Borehole inspecting and testing device and method of using the same

a technology of borehole and inspection device, which is applied in the direction of borehole/well accessories, survey, construction, etc., can solve the problems of saving significant amounts of money in the overall cost of the pile, and achieve the effects of saving more money, increasing the design load, and reducing the safety margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

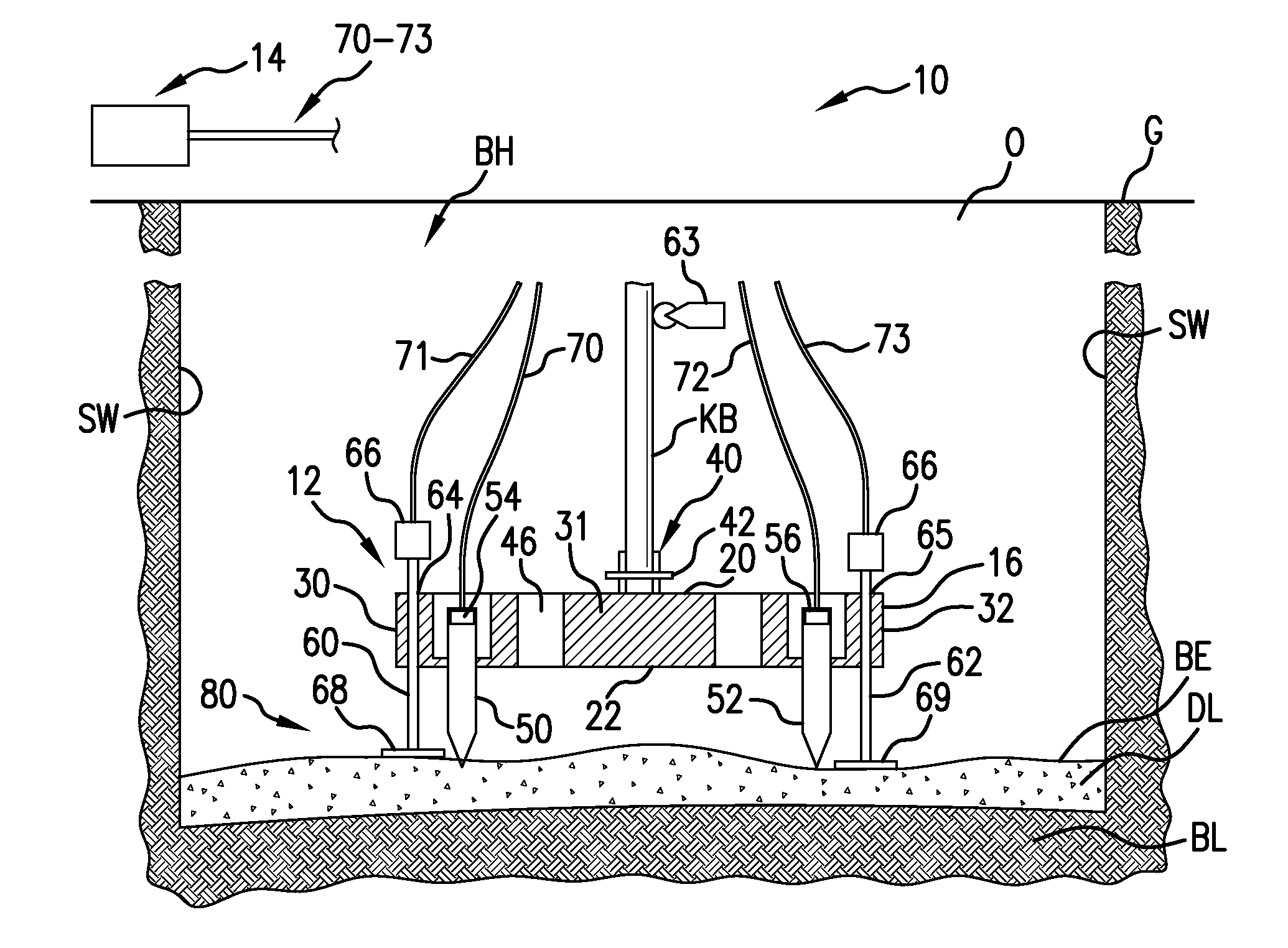

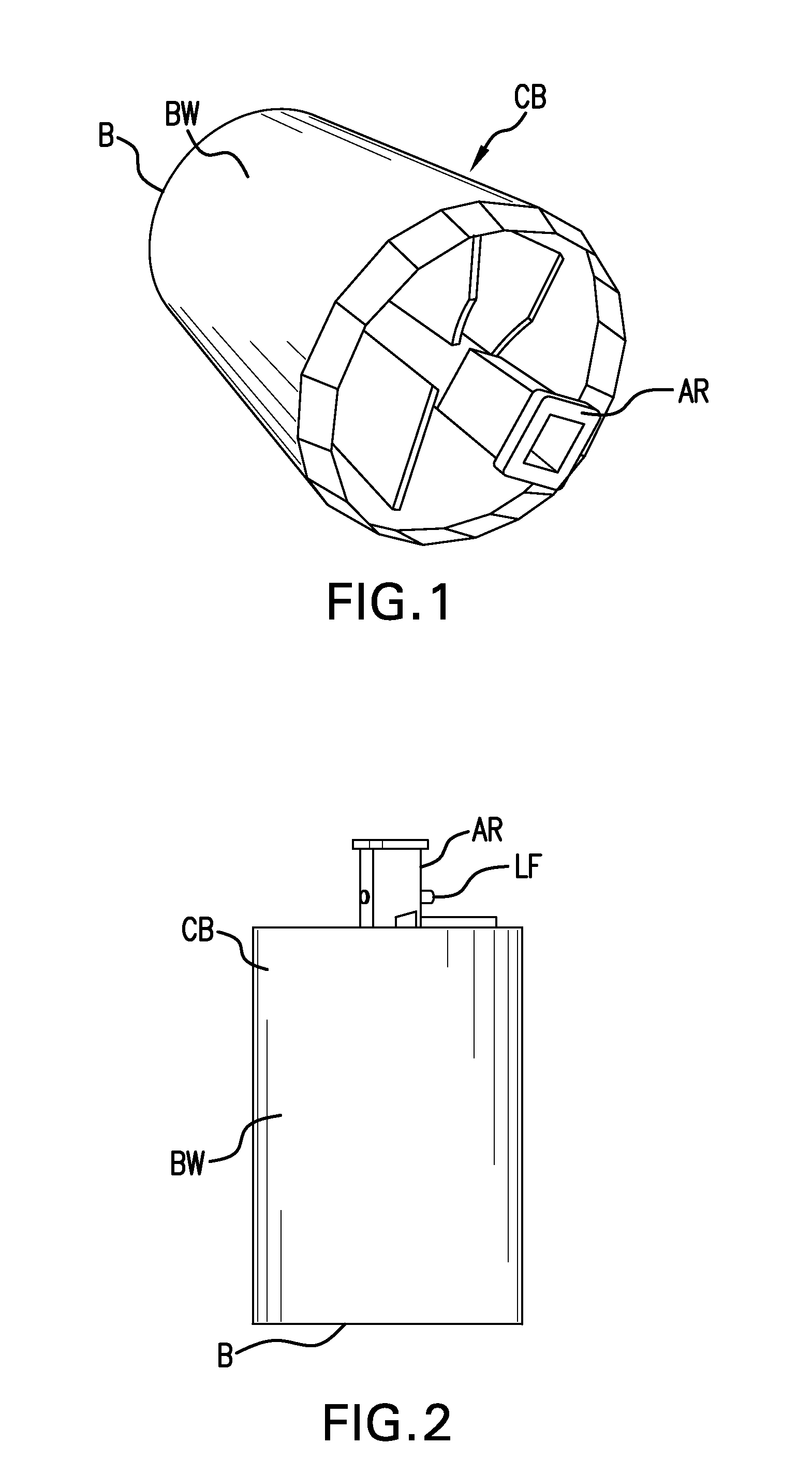

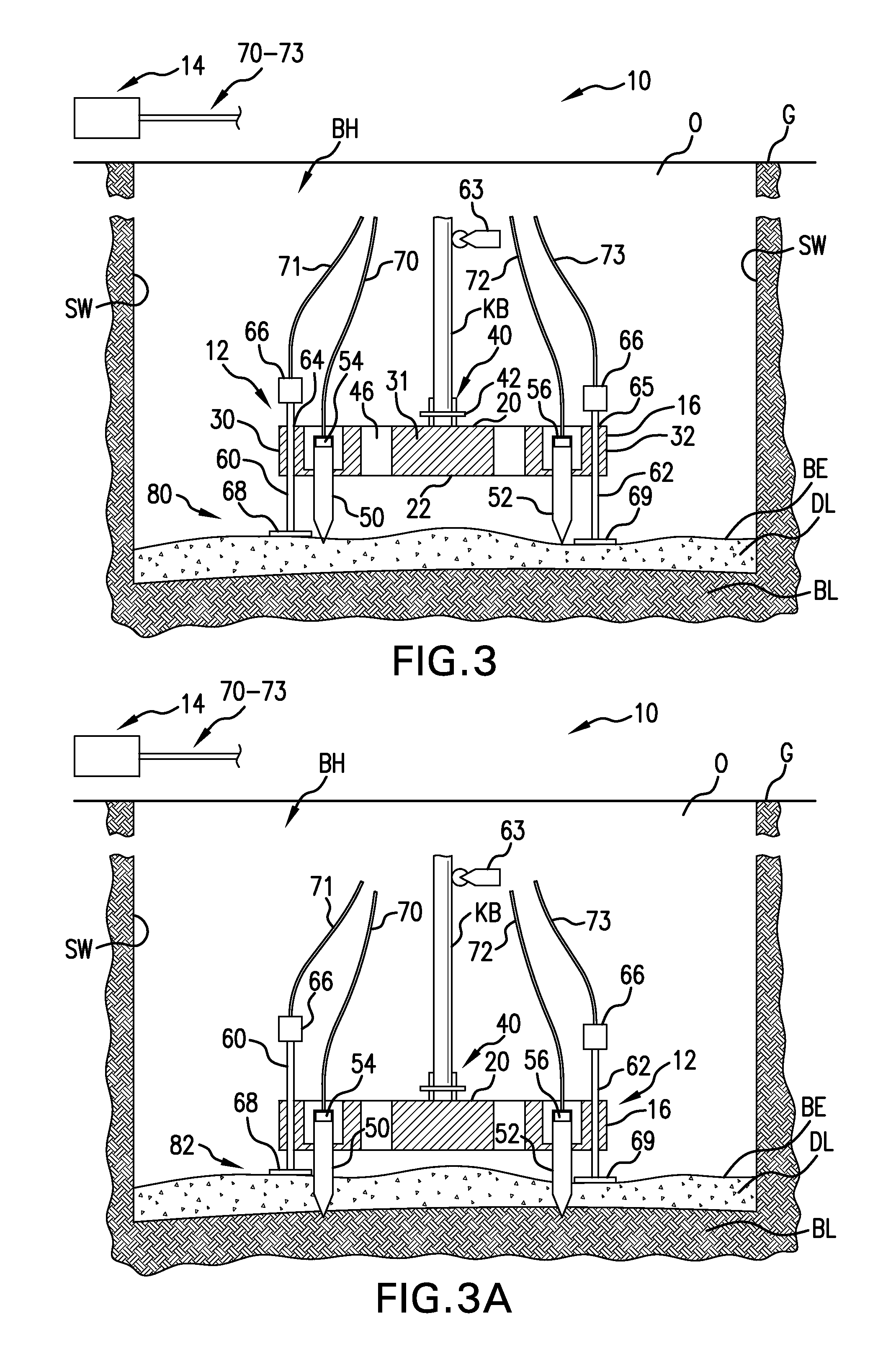

[0049]Referring now to the drawings wherein the showings are for the purpose of illustrating preferred and alternative embodiments of the invention only and not for the purpose of limiting the same, FIGS. 1 and 2 show a prior art clean out bucket CB which includes a mounting arrangement AR configured to selectively secure the bucket to a drilling mast, drillstem or Kelly bar (not shown in these figures). These masts have a square cross-sectional configuration wherein the mounting arrangement can be sized to slide over the mast and includes a locking features LF to secure the bucket relative to the mast. However, any attachment configuration could be used without detracting from the invention of this application. By including a square configuration, the mast can impart a rotational force on the bucket. The bucket further includes one or more side walls BW and a bottom B having a blade and a blade opening (both not shown). In operation the bucket is rotated such that the blade directs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com