Film bag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

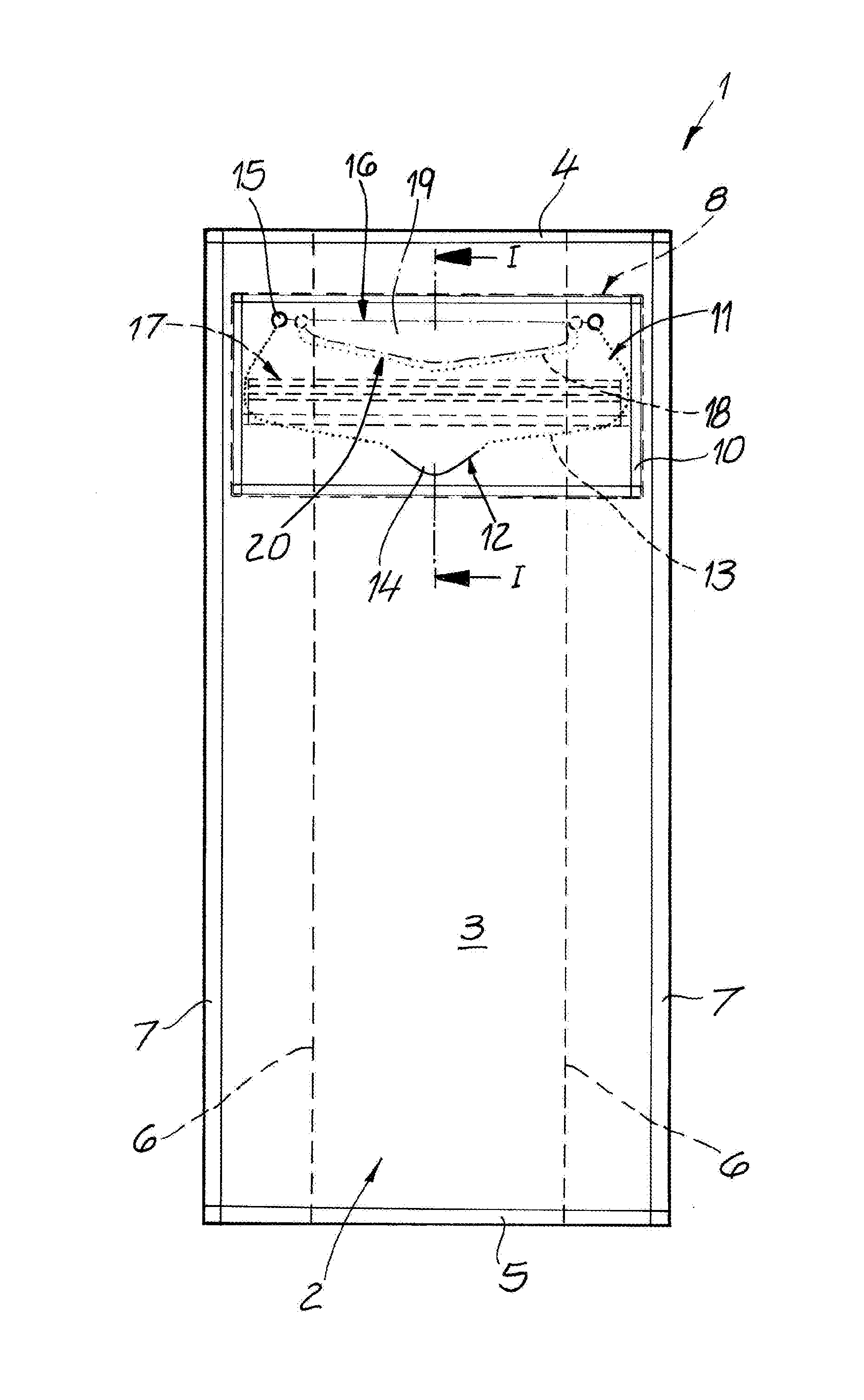

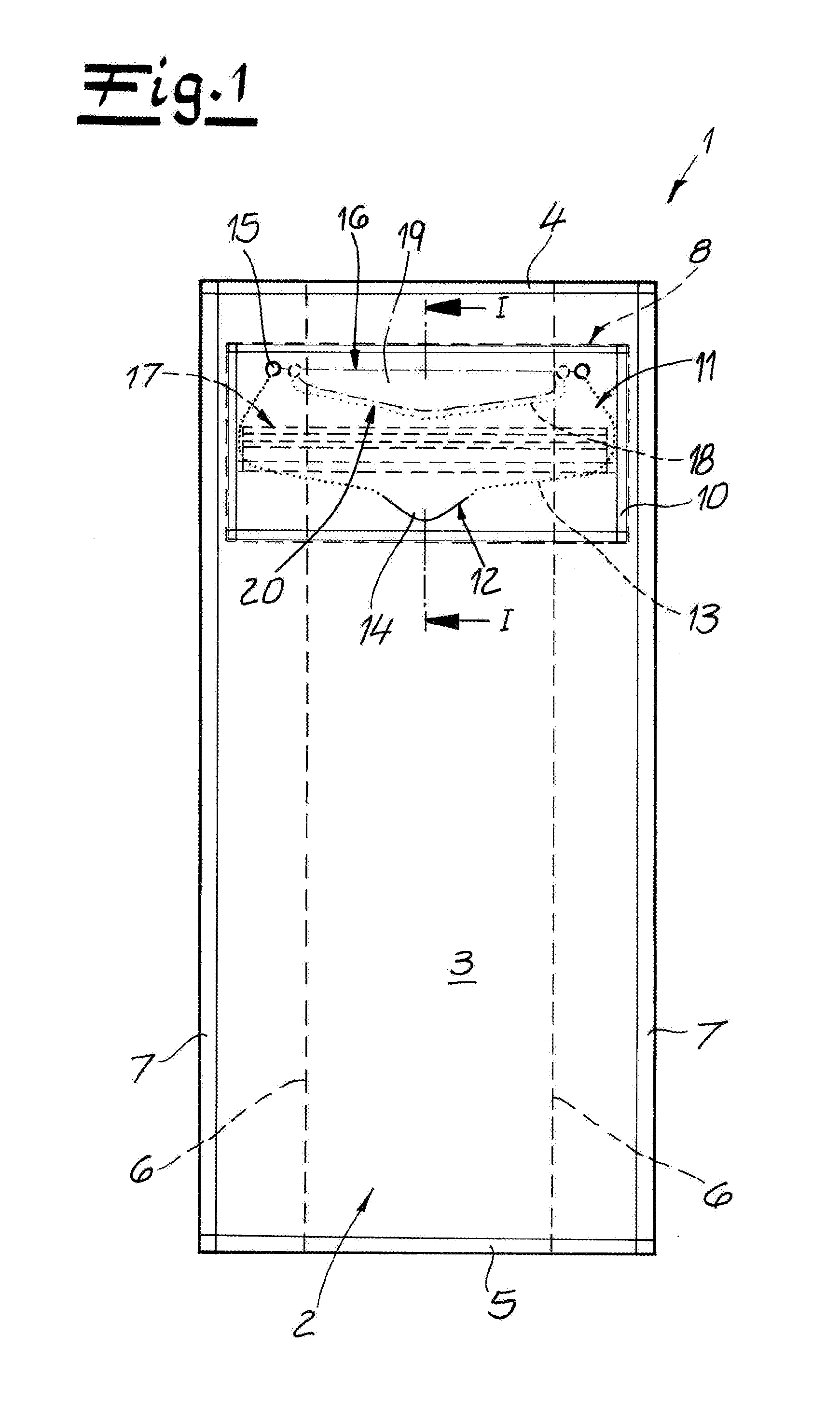

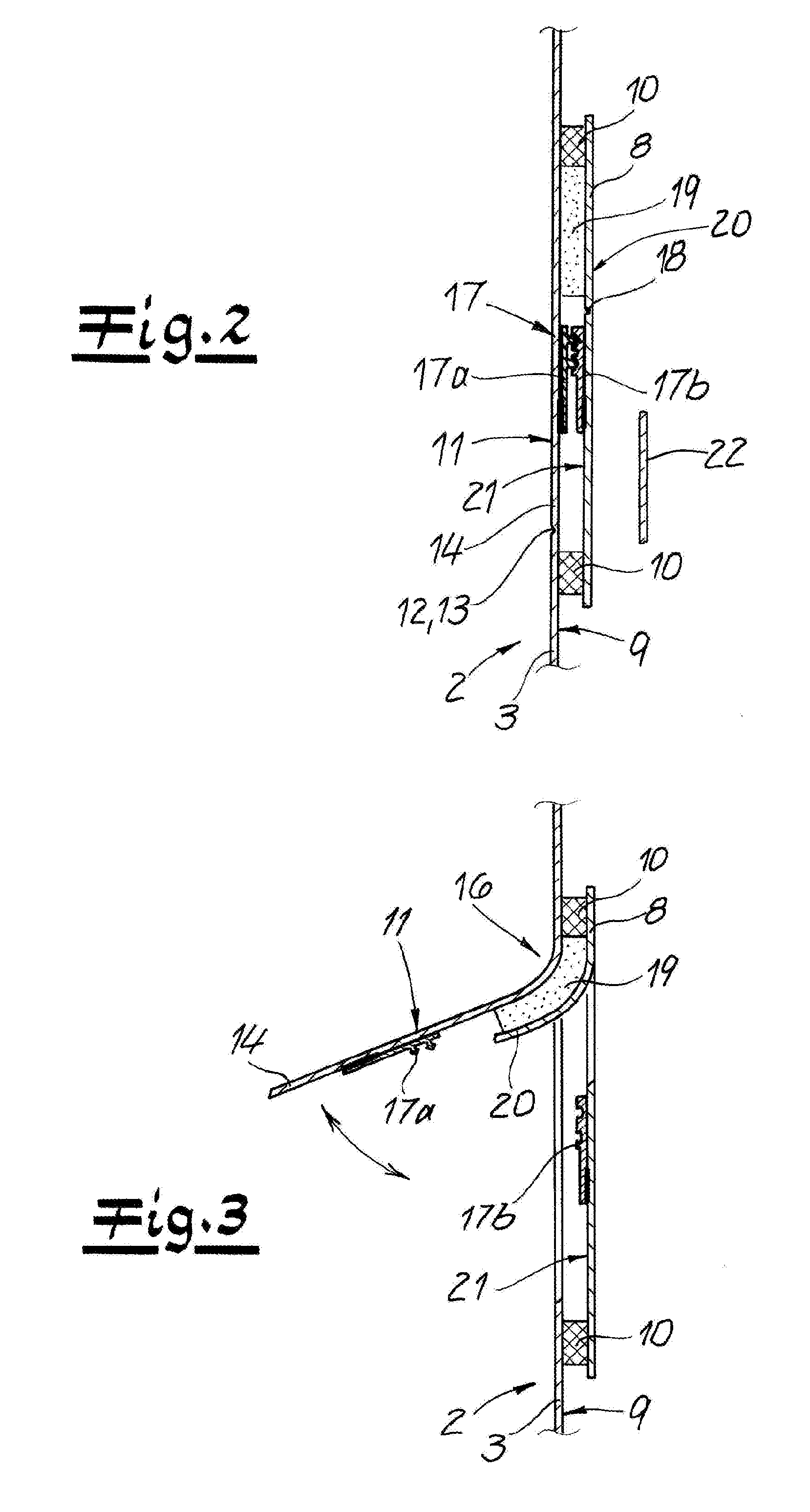

[0026]As seen in FIG. 1 a film bag 1 according to the invention has a front panel 2 with a front face 3 and a geometrically similar opposite back panel 22 with a back face and only shown partially in FIG. 2. The front panel 2 and back panel 22 are joined directly by parallel top bottom welds 4 and 5. Side gussets with fold lines 6 shown by a dashed line are folded between side edges of the panels 3 and 22 and secured thereto by side or longitudinal welds 7.

[0027]According to the invention, a rectangular inner cover patch 8 is connected to an inner face 9 of the front panel 3 by a continuous rectangular frame weld 10. The frame weld 10 is formed thermally.

[0028]A flap 11 is formed by a cut line 12 and two adjoining weakening lines 13 in the material of the front panel 2 surrounded by the frame weld 10. The full cut 12 defines a grip tab 14 of the flap 11 whereas the rest of the flap 11 is defined by the weakening lines 13 formed by rows of perforations. The ends of the weakening line...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesivity | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Weldability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com