Method of setting flying height and flying height setting device

a technology of magnetic recording head and setting device, which is applied in the direction of combination recording, data recording, instruments, etc., can solve the problems of difficult to precisely detect touch down relative to the magnetic recording medium of damage to the thermally-assisted magnetic recording head and the magnetic recording medium,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

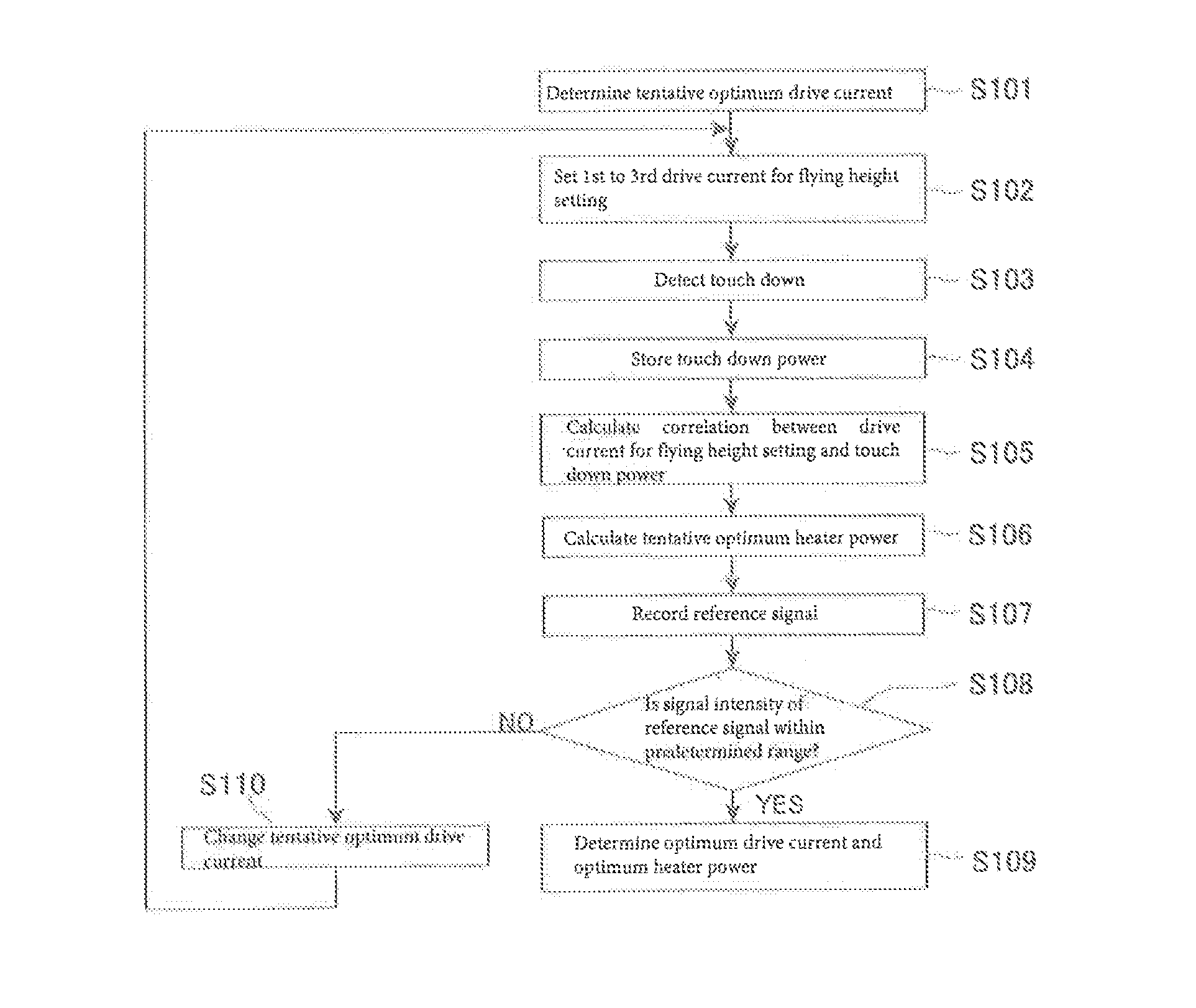

[0135]The thermally-assisted magnetic disk device having a configuration shown in FIGS. 1 to 6 was prepared, and the tentative optimum drive current LDI0 of the laser diode 60 in the thermally-assisted magnetic recording head 1 was determined. The tentative optimum drive current LDI0 was determined to 35 mA, which would be greater than a threshold current Ith (=15.5 mA) to start the laser oscillation in the laser diode 60.

[0136]Then, based on the formulae below, the 1st to 3rd drive currents for flying height setting LDI1 to LDI3, which would be 50%, 60% and 70% of the tentative optimum drive current LDI0, were calculated and set.

LDI1=(LDI0−Ith)×0.5+Ith=25.25 mA

LDI2=(LDI0−Ith)×0.6+Ith=27.20 mA

LDI3=(LDI0−Ith)×0.7+Ith=29.15 mA

[0137]The 1st to 3rd drive currents for flying height setting LDI1 to LDI3 were supplied to the laser diode 60, respectively; the heater power HTP was supplied to the heater part HT, a write current IW (=65 mA) was supplied to the writing coil 22e, and while the ...

experimental example 1

Measurement of Protrusion Shape Profile of Medium Opposed Surface (Head Part End Surface) in Thermally-Assisted Magnetic Recording Head

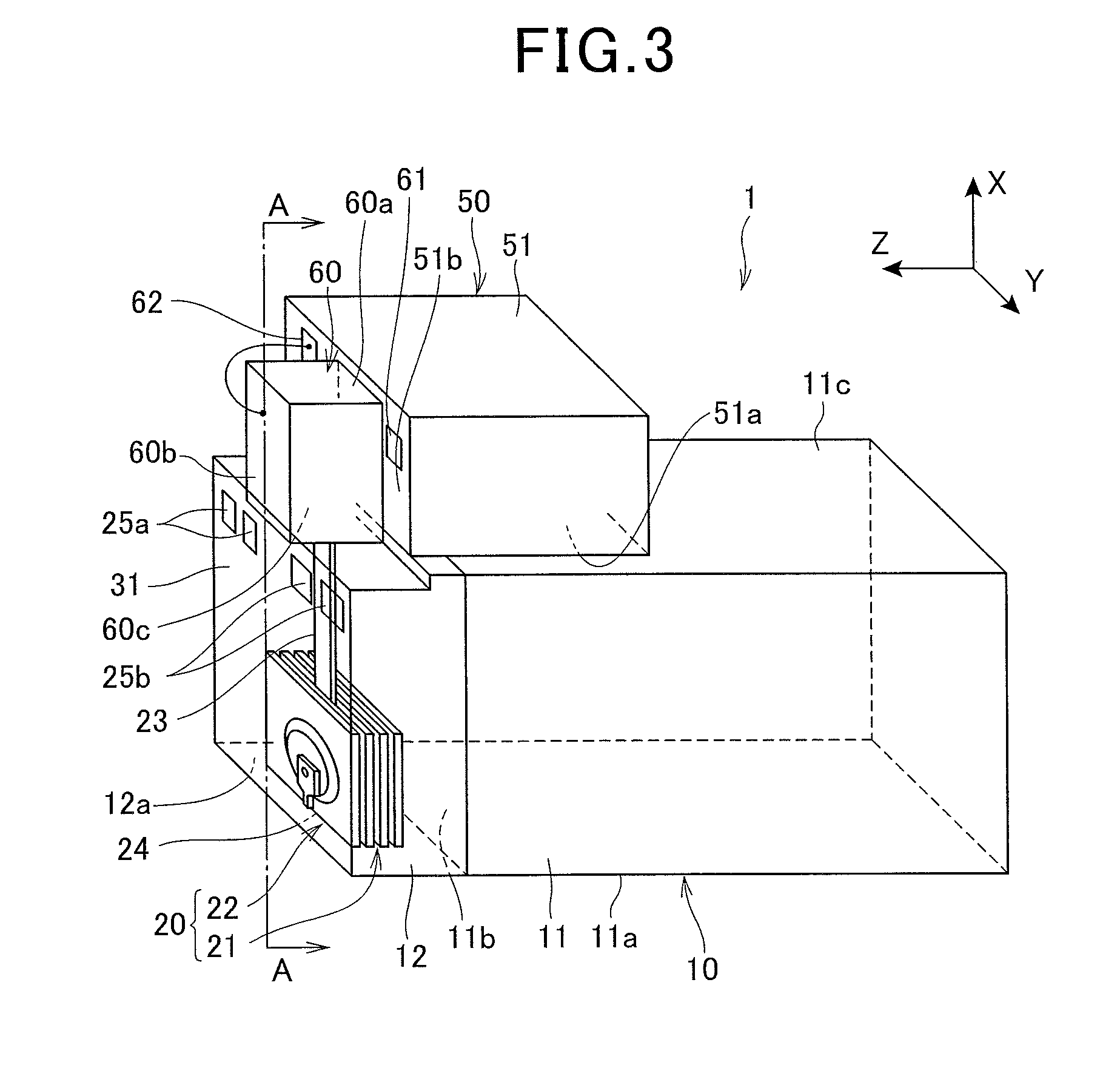

[0143]For the protrusion shape of the head part end surface 12a in the thermally-assisted magnetic recording head 1 in Example 1, a simulation analysis experiment was conducted.

[0144]This simulation analysis experiment was conducted using a finite element method.

[0145]In the present experimental example, a model where the waveguide 23 in the thermally-assisted magnetic recording head 1, the dielectric layer 32f contacting the side surface 23c of the waveguide 23 and the plasmon-generator 24 were made from TaOX, SiOX and Au, respectively, was adopted.

[0146]Further, in the model, width of the magnetic pole 22f in the track width direction (Y-axis direction), width of the waveguide 23 in the track width direction (Y-axis direction), height of the magnetic pole 22f in the Z-axis direction and height of the waveguide 23 in the Z-axis direction were set to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com