A kind of n-type topcon battery with double-sided aluminum paste electrodes and preparation method thereof

An N-type, battery technology, applied in the field of solar cells, can solve the problems of increasing the diffusion length of carriers, reducing the cost of battery production, and low photoelectric conversion efficiency, and achieving the effects of reducing laser damage, improving Voc, and improving battery efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the N-type Topcon battery with double-sided aluminum paste electrodes, the preparation process is: texture → B diffusion → BSG removal → alkali polishing → back LPCVD deposition tunnel oxide layer and polysilicon layer → back P diffusion → removal PSG → dewinding plating → front AlO x layers and SiN x h y Layer Deposition → Backside SiN x h y Deposition → front / back UV laser ablation → screen printing. Including the following specific preparation steps:

[0041] A. Preparation of N-type double-sided cells before metallization, using N-type single crystal silicon wafers as the substrate, and the front side of the N-type silicon wafers are sequentially diffused by B to form a P-type doped region layer, deposited by PECVD with a thickness of 2-15nm AlO x layer and SiN with a thickness of 50-100 nm x h y layer, on the back of the N-type silicon wafer, a tunnel oxide layer with a thickness of 1-8mm is deposited sequentially by LPCVD, and an ...

Embodiment 1

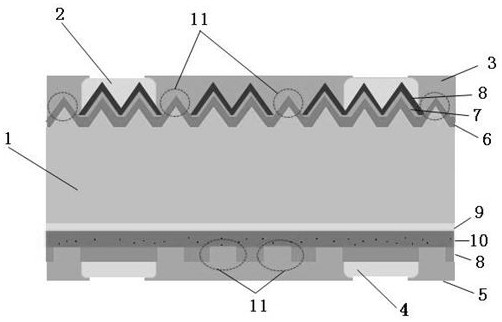

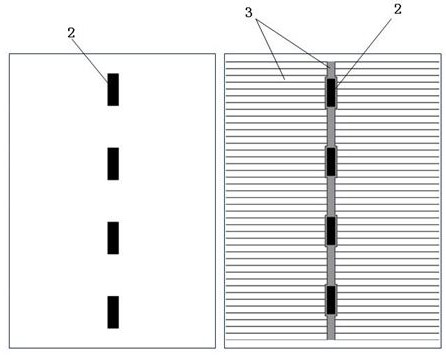

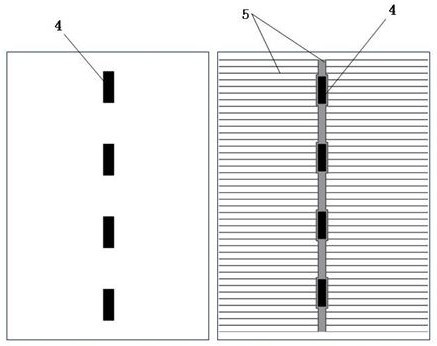

[0046] An N-type Topcon battery with double-sided aluminum paste electrodes, including an N-type substrate 1, the front of the N-type substrate 1 is sequentially provided with a P-type doped region layer 6, AlO x Layer 7 and SiN x h y layer 8, the back of the N-type substrate 1 is sequentially provided with a tunnel oxide layer 9, an N-type doped polysilicon layer 10 and SiN x h y Layer 8, the front side of the SiN x h y Layer 8 is provided with front silver main grid 2 and front aluminum fine grid 3, and the SiN x h y The back silver main grid 4 and the rear aluminum fine grid 5 are arranged on the layer 8 .

[0047] The thickness of the front silver busbar 2 is smaller than the thickness of the front aluminum fine grid 3, the front silver busbar 2 is distributed in the front aluminum fine grid 3, the thickness of the rear silver busbar 4 is smaller than the thickness of the rear aluminum fine grid 5, and the back silver busbar 4 are distributed in the back aluminum fi...

Embodiment 2

[0054] An N-type Topcon battery with double-sided aluminum paste electrodes, including an N-type substrate 1, the front of the N-type substrate 1 is sequentially provided with a P-type doped region layer 6, AlO x Layer 7 and SiN x h y layer 8, the back of the N-type substrate 1 is sequentially provided with a tunnel oxide layer 9, an N-type doped polysilicon layer 10 and SiN x h y Layer 8, the front side of the SiN x h y Layer 8 is provided with front silver main grid 2 and front aluminum fine grid 3, and the SiN x h y The back silver main grid 4 and the rear aluminum fine grid 5 are arranged on the layer 8 .

[0055] The thickness of the front silver busbar 2 is smaller than the thickness of the front aluminum fine grid 3, the front silver busbar 2 is distributed in the front aluminum fine grid 3, the thickness of the rear silver busbar 4 is smaller than the thickness of the rear aluminum fine grid 5, and the back silver busbar 4 are distributed in the back aluminum fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com