Puming system

a pumping system and pumping tube technology, applied in the direction of pump control, flexible member pump, positive displacement liquid engine, etc., can solve the problems of limiting the rate at which the bladder in each vessel is filled with water, reducing the efficiency of pumping, and reducing the cost of vessels to manufacture, so as to facilitate the assembly of the pumping apparatus and achieve the effect of smooth operation and equal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

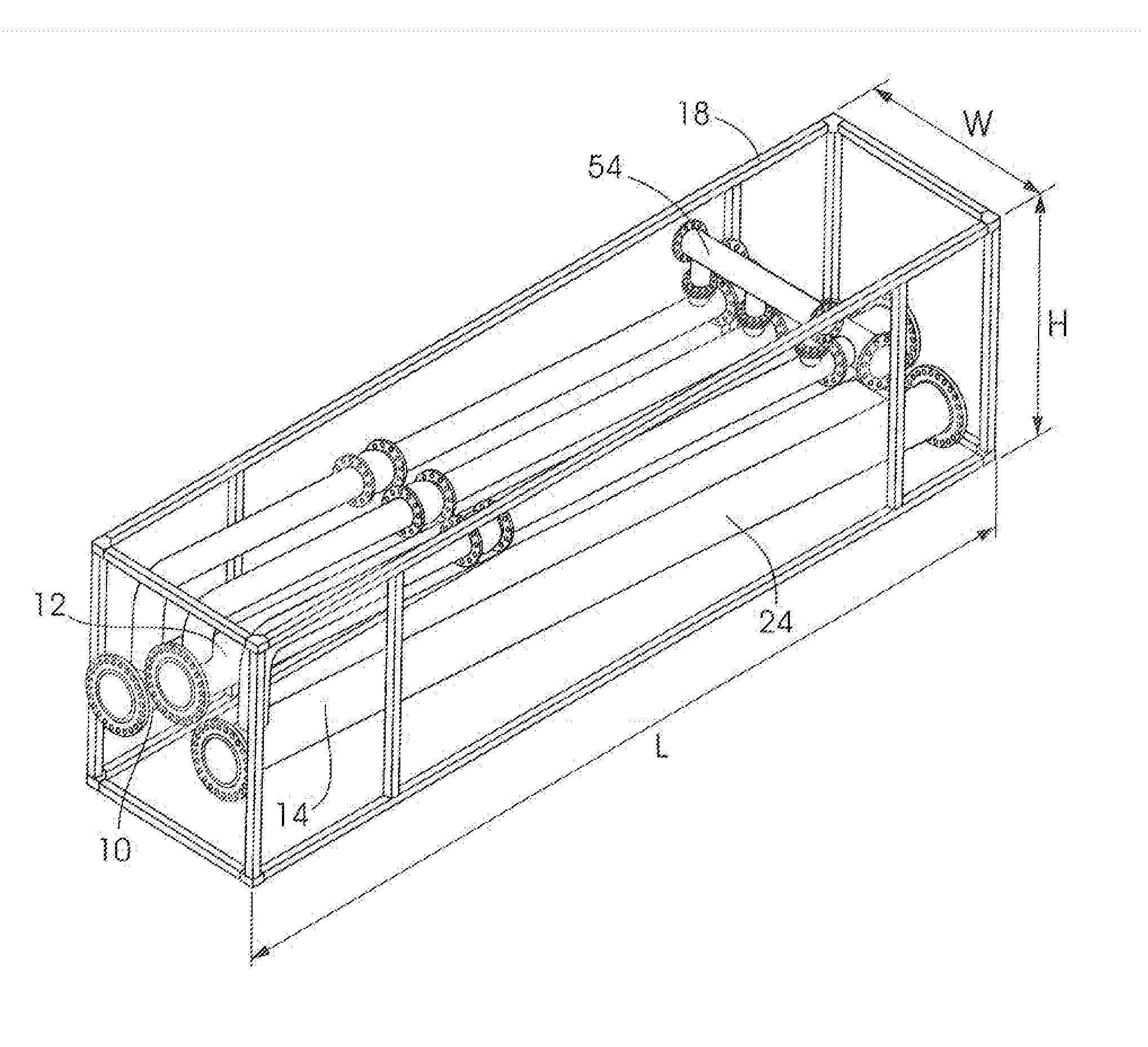

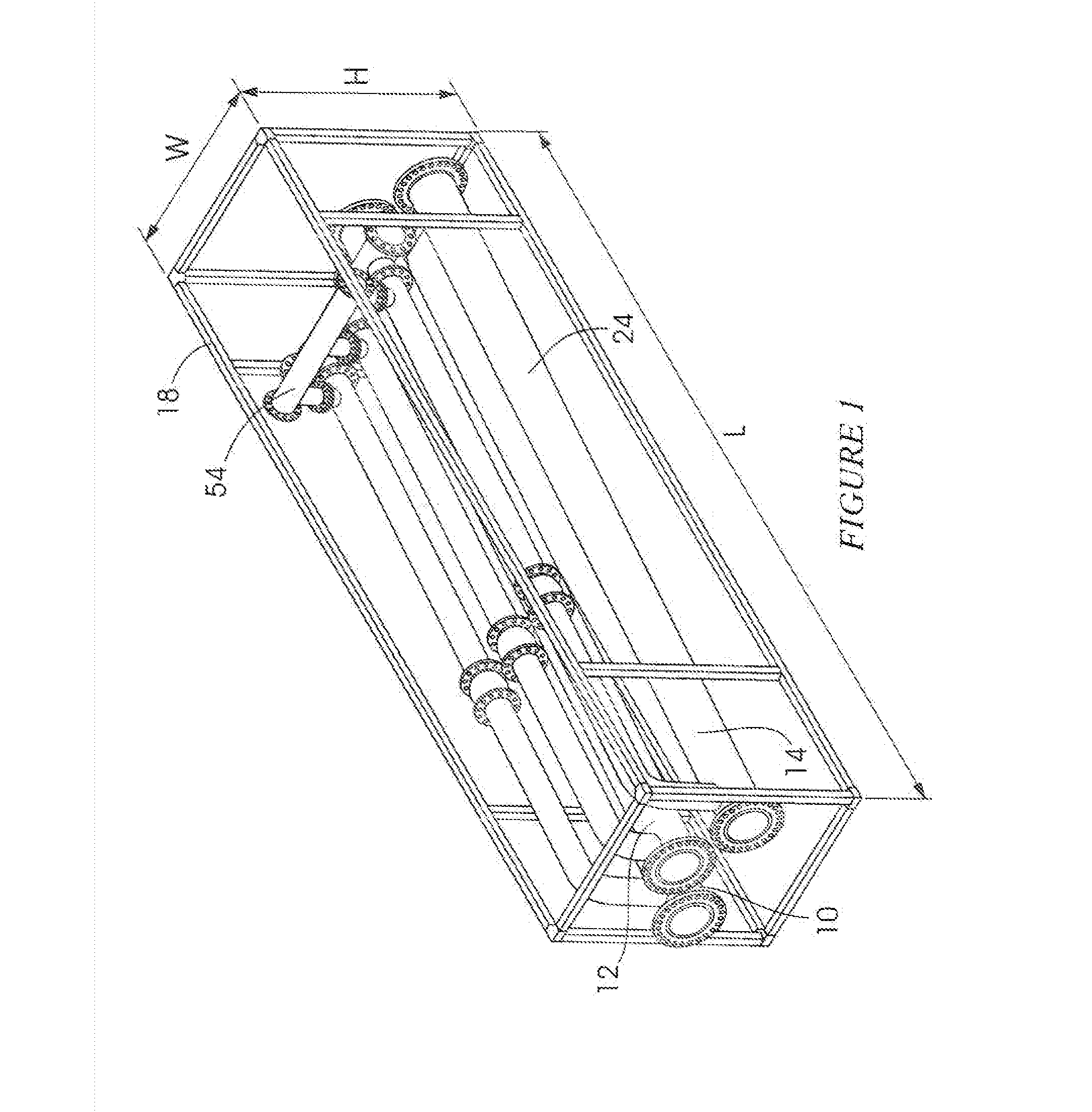

[0067]FIGS. 1 to 4 are different views of three pump units 10, 12 and 14 respectively which are mounted to supporting structure 18.

[0068]The supporting structure is shown in skeletal form. Typically the supporting structure is embodied in, or constituted by, a conventional transport container i.e. the structure 18 has a length L, a height H and a width W (FIG. 1) which conform to the dimensions of a conventional container. Sides of the supporting structure are not closed—this facilitates access to equipment mounted to the structure.

[0069]The construction of the unit 14 only is described hereinafter. The units 10 and 12 are similar to the unit 14.

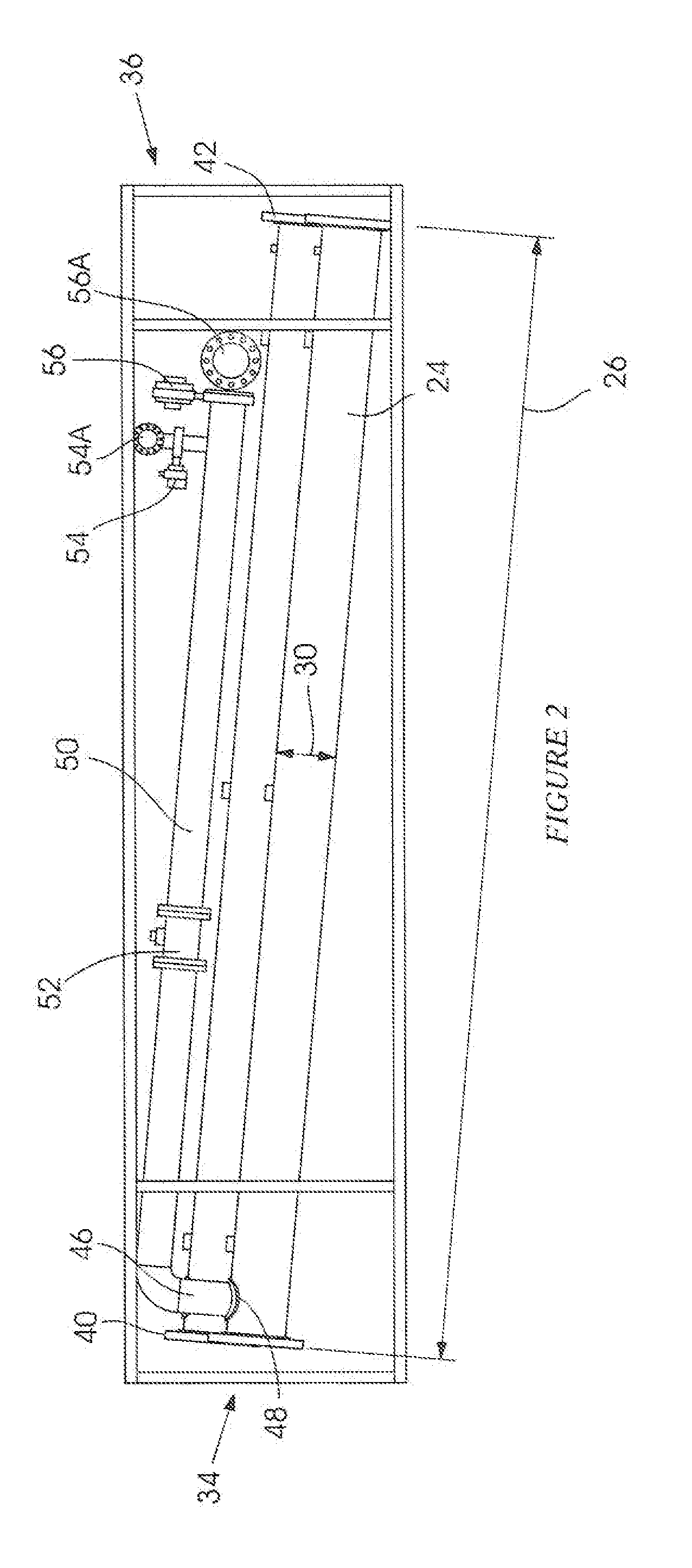

[0070]The unit 14 includes an elongate tubular housing 24 in the form of a pipe which is made to a suitable specification and which has a length 26 and a diameter 30. The pipe 24 has a first end 34 and an opposing second end 36. Each end is provided with a respective flange 40, 42.

[0071]Near the first end 34 (FIG. 2) the pipe 24 is formed wi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap