Vaporisable material

a technology of vaporizers and liquids, applied in the field of vaporizers, can solve the problems of unreliable flavour/taste delivery to users, devices not always popular with consumers,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

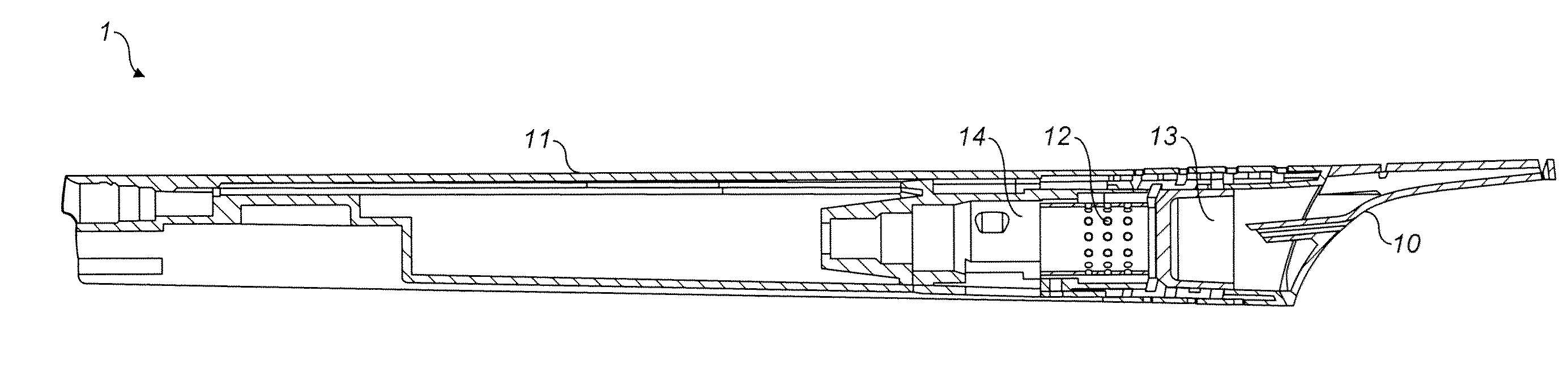

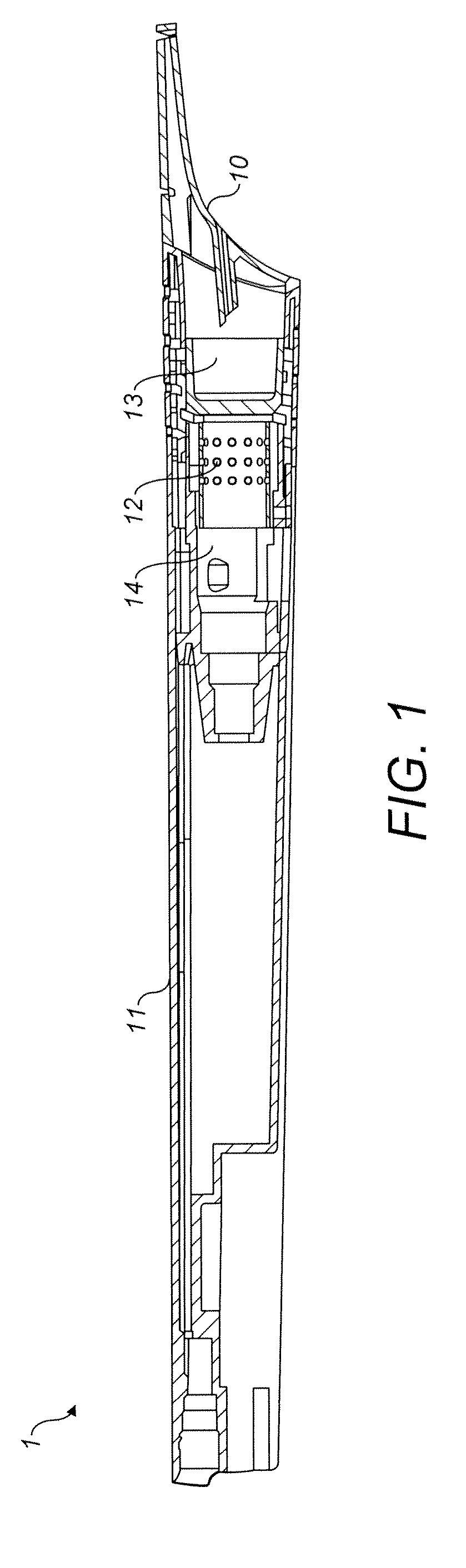

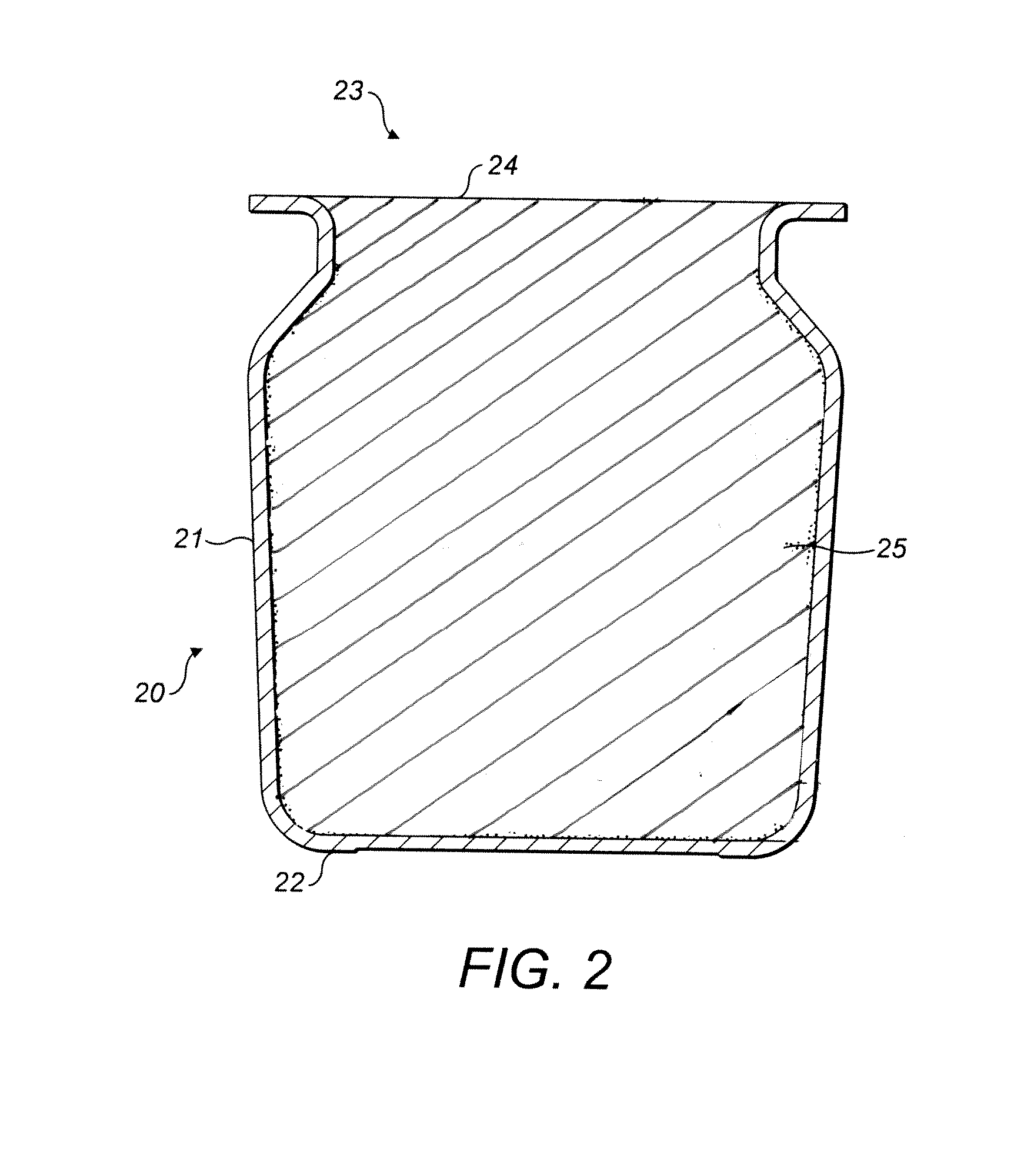

Image

Examples

Embodiment Construction

[0011]As used herein, the term “moisture content” refers to the amount of moisture (i.e. water) present in a given material, e.g. vaporisable material, including plant material such as tobacco.

[0012]As used herein, the term “vaporisable” has its usual meaning in the art, referring to a material that is capable of being converted to from a solid or liquid state to a gaseous state upon heating.

[0013]Moisture content is an important parameter of the chemical composition of vaporisable materials, and in particular of the plant material such as tobacco. The moisture content of vaporisable materials, and the components of vaporisable materials, may affect various properties of the material, including:[0014]Ease of particle size reduction, with drier materials being easier to mill into fine powders;[0015]Texture and density, with wetter materials being of higher density and more sticky; and[0016]Efficiency of vapour production upon heating, since the moisture content affects the time and e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com