Rotary engine having two rotors with intersecting pathways

a technology of rotors and paths, applied in the field of engine efficiency enhancement, can solve the problems of relatively inefficient conventional engines, loss of energy from combustion of air/fuel mixture, and relatively complex structure of engines, and achieve the effects of enhancing engine efficiency, enhancing engine efficiency, and prolonging strok

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

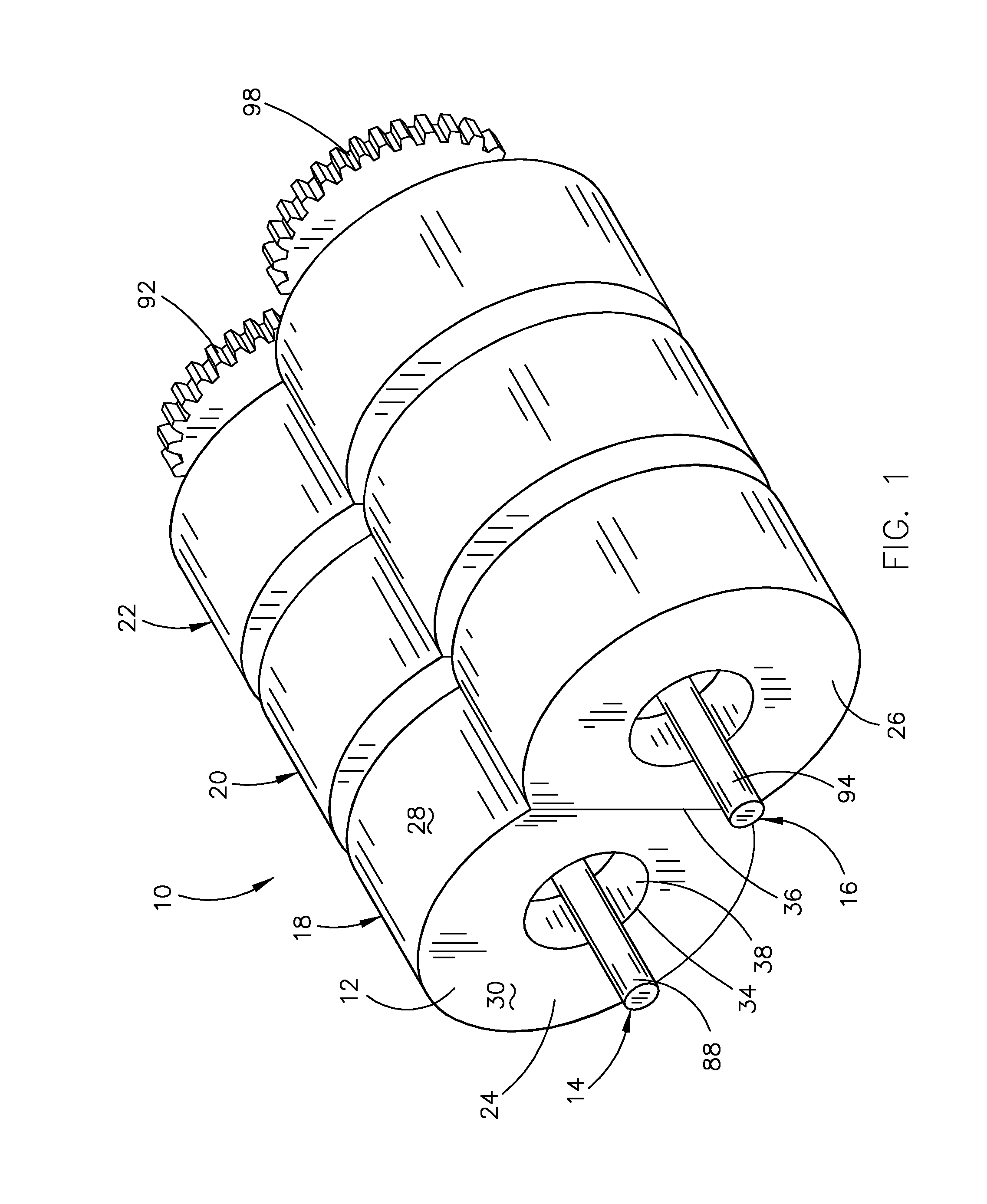

[0030]The present invention is directed to an engine with first and second rotors that rotate in a direction that does not oppose the expansion of a combusted air / fuel mixture within the combustion chambers to thereby enhance the engine's efficiency. While the invention will be described in detail below with reference to exemplary embodiments of an engine intended to be mounted within a vehicle, it should be understood that the invention is not limited to the specific structural configurations of these embodiments or to the particular application within a vehicle. For example, the engine could have other structural configurations and could be used in other applications, such as engines for electric generators or lawn and garden equipment. In addition, although the exemplary embodiments are described as embodying several different inventive features, one skilled in the art will appreciate that any one of these features could be implemented without the others in accordance with the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com