Polysaccharide fibers and method for producing same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

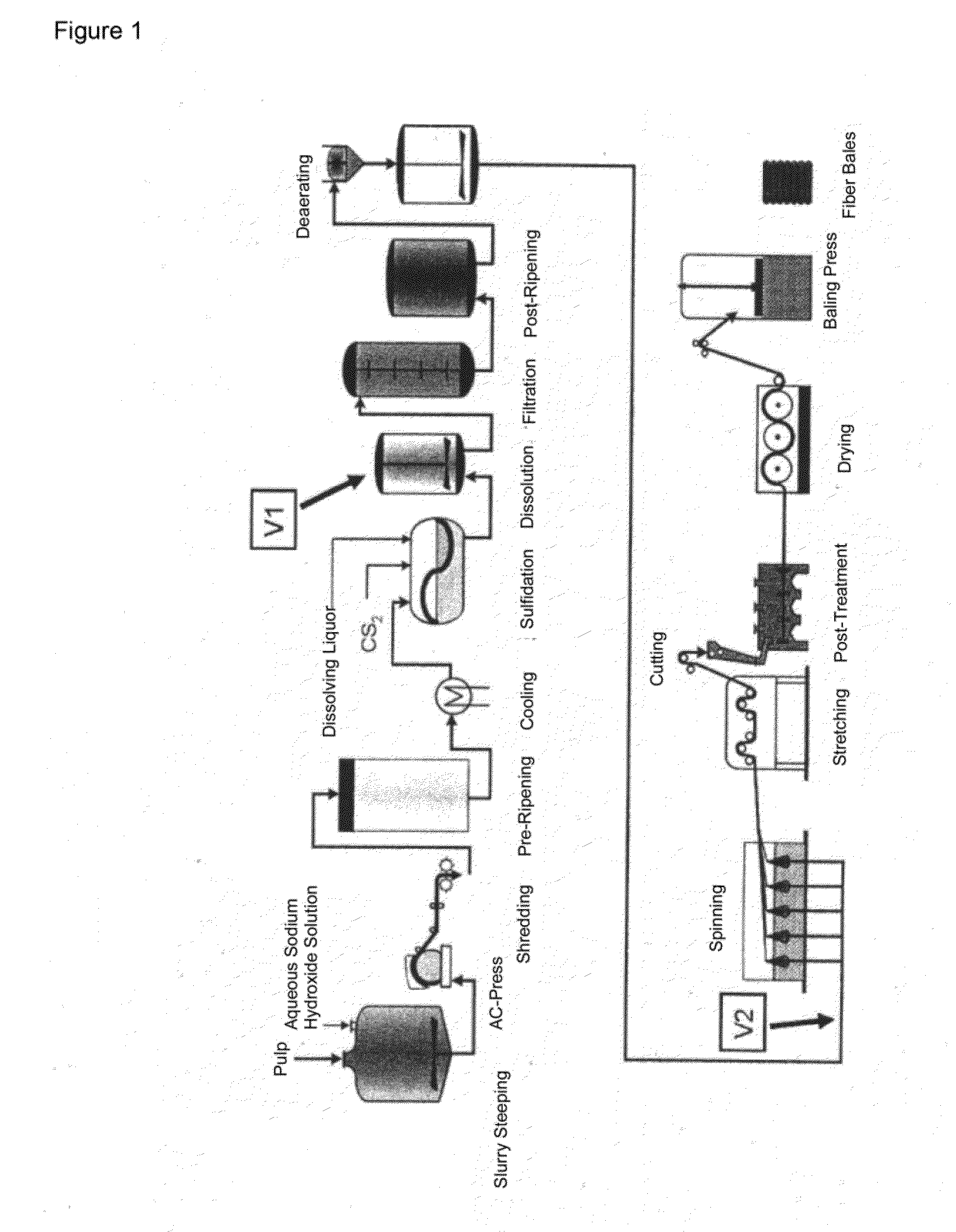

Method used

Image

Examples

example 1

[0033]A viscose xanthogenate containing 29.8% by weight of cellulose, 14.9% by weight of alkali, and 8% by weight of sulfur was reacted in a dissolving unit with a first dissolving liquor containing 4.5% by weight of NaOH and then with a second dissolving liquor containing 9% by weight of α(1→3)-glucan and 4.5% by weight of NaOH and finally with water. The viscose obtained in this way contains 9% by weight of fiber-forming material, 5.20% by weight of alkali, and 2.4% by weight of sulfur (calculated under the assumption that there are 100% by weight of cellulose as a fiber-forming material), with a ripeness index of 14 Hottenroth and a falling ball viscosity of 80 seconds (determined according to the Zellcheming Leaflet III / 5 / E). Viscose solutions with 10 and 25% of α(1→3)-glucan were prepared. These glucan quantities were related to the proportion of the α(1→3)-glucan in the fiber-forming substance. These viscose types contain 2.2% by weight of sulfur (10% by weight of glucan and 9...

example 2

[0036]A viscose containing 8.70% by weight of cellulose, 5.20% by weight of alkali, and 2.3% by weight of sulfur, with a ripeness index of 15 Hottenroth and a falling ball viscosity of 75 seconds (determined according to the Zellcheming Leaflet III / 5 / E), was, by means of a spinneret, extruded into a regeneration bath containing 100 g / l of sulfuric acid, 310 g / l of sodium sulfate, and 15 g / l of zinc sulfate. The spinneret had 1053 perforations with a diameter of 50 μm. 0.5% by weight of a nitrogen-containing auxiliary agent were added to the viscose spinning solution. In order to achieve adequate fiber strength, stretching by approx. 75% was carried out in the second bath (92° C., 15 g / l of H2SO4). The draw-off velocity was 50 m / min.

[0037]By using a positive displacement pump, various weight / weight percentages of a α(1→3)-glucan solution (prepared with 5% by weight of NaOH, 8% by weight of α(1→3)-glucan) were added to the viscose solution upstream from the spinneret, and fibers havin...

example 3

[0040]A modal viscose containing 6.0% by weight of cellulose, 6.20% by weight of alkali, and 1.8% by weight of sulfur, with a gamma value of 65 and a falling ball viscosity of 130 seconds (determined according to the Zellcheming Leaflet III / 5 / E) was, by means of a spinneret, extruded into a regeneration bath containing 72 g / l of sulfuric acid, 115 g / l of sodium sulfate, and 55 g / l of zinc sulfate. The spinneret had 1053 perforations with a diameter of 45 μm. 2.5% by weight of a nitrogen-containing auxiliary agent were added to the viscose spinning solution. In order to achieve adequate fiber strength, stretching by approx. 115% was carried out in the second bath (92° C., 15 g / l of H2SO4). The draw-off velocity was 50 m / min.

[0041]By using a positive displacement pump, various weight / weight percentages of a α(1→3)-glucan solution (prepared with 5% by weight of NaOH, 4.5% by weight of α(1→3)-glucan) were added to the viscose solution upstream from the spinneret, and fibers having 5 and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com