Non-adhesive false eyelash system and method

a false eyelash and non-adhesive technology, applied in the field of false eyelashes, can solve the problems of eyelash hairs that cannot be reused, cannot be applied again, and cannot be applied to the same eyelash, etc., and achieve the effect of convenient removal and reapplying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

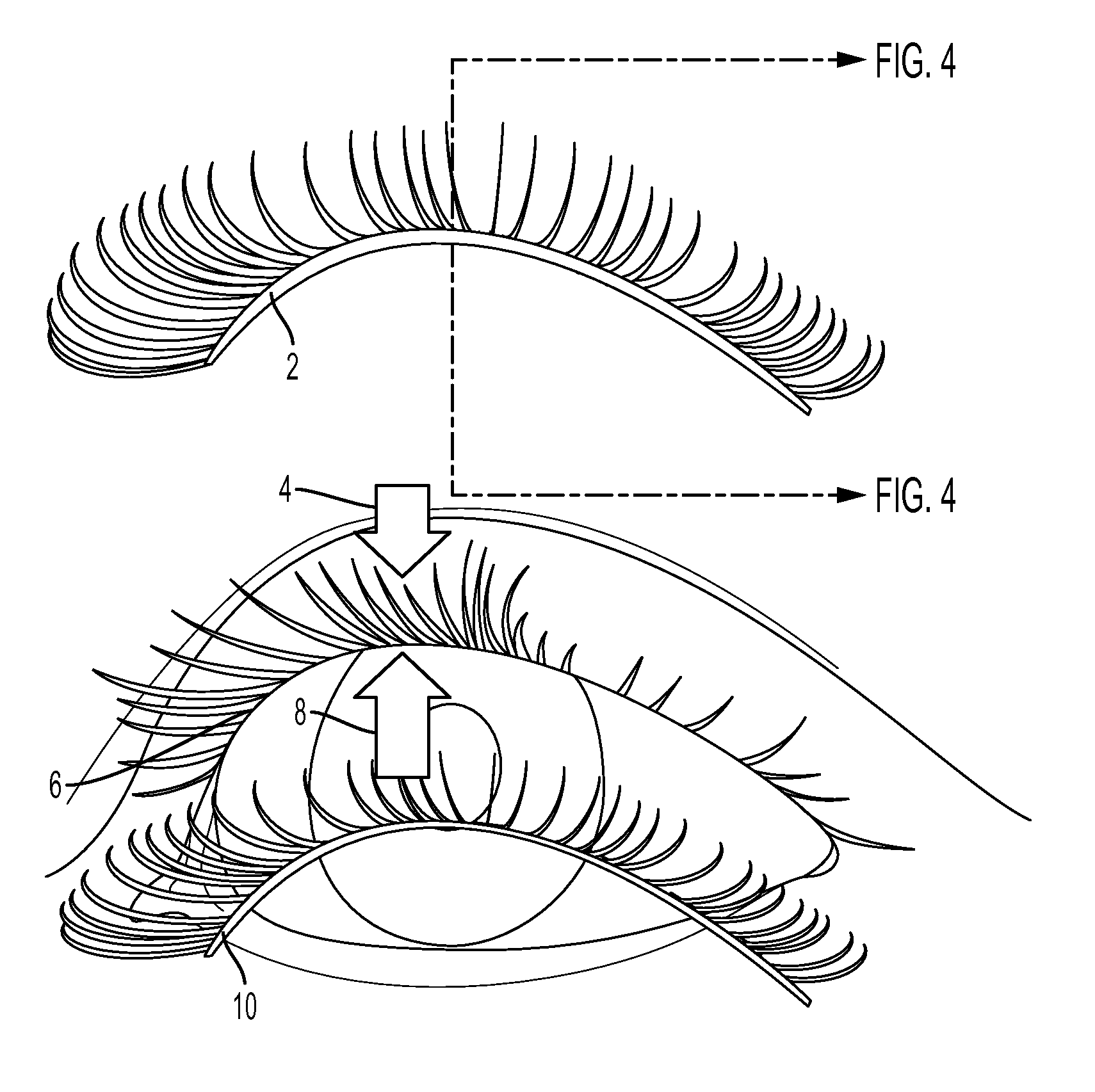

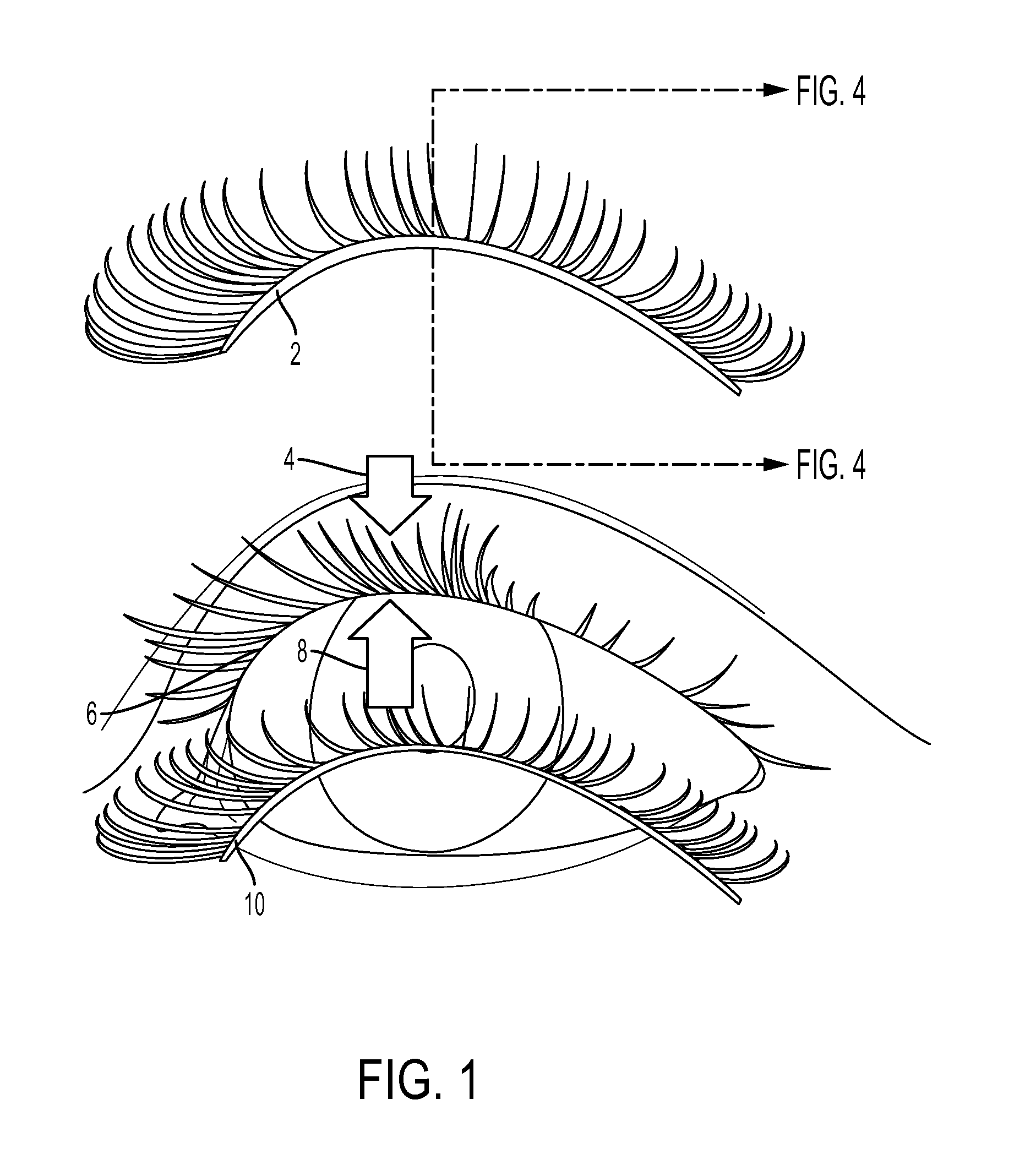

[0028]Referring first to FIG. 1 of the drawings, shown therein is a frontal view of a human eye in which a magnetic embodiment of the false eyelash of the present invention is about to be installed on the upper eyelash (6) of the wearer. The upper eyelash assembly (2) and lower eyelash assembly (10) are in position, respectively above and below the upper eyelash (6) of the wearer. In order to apply the false eyelash, the upper eyelash assembly (2) is moved in a downward direction (4) towards the wearers upper eyelash (6) while the lower eyelash assembly (10) is moved in an upward direction (8) towards the towards the wearer's upper eyelash (6). As the upper and lower assemblies (2,10) approach each other, magnetic force urges them towards each other “sandwiching” the wearer's upper eyelash (6).

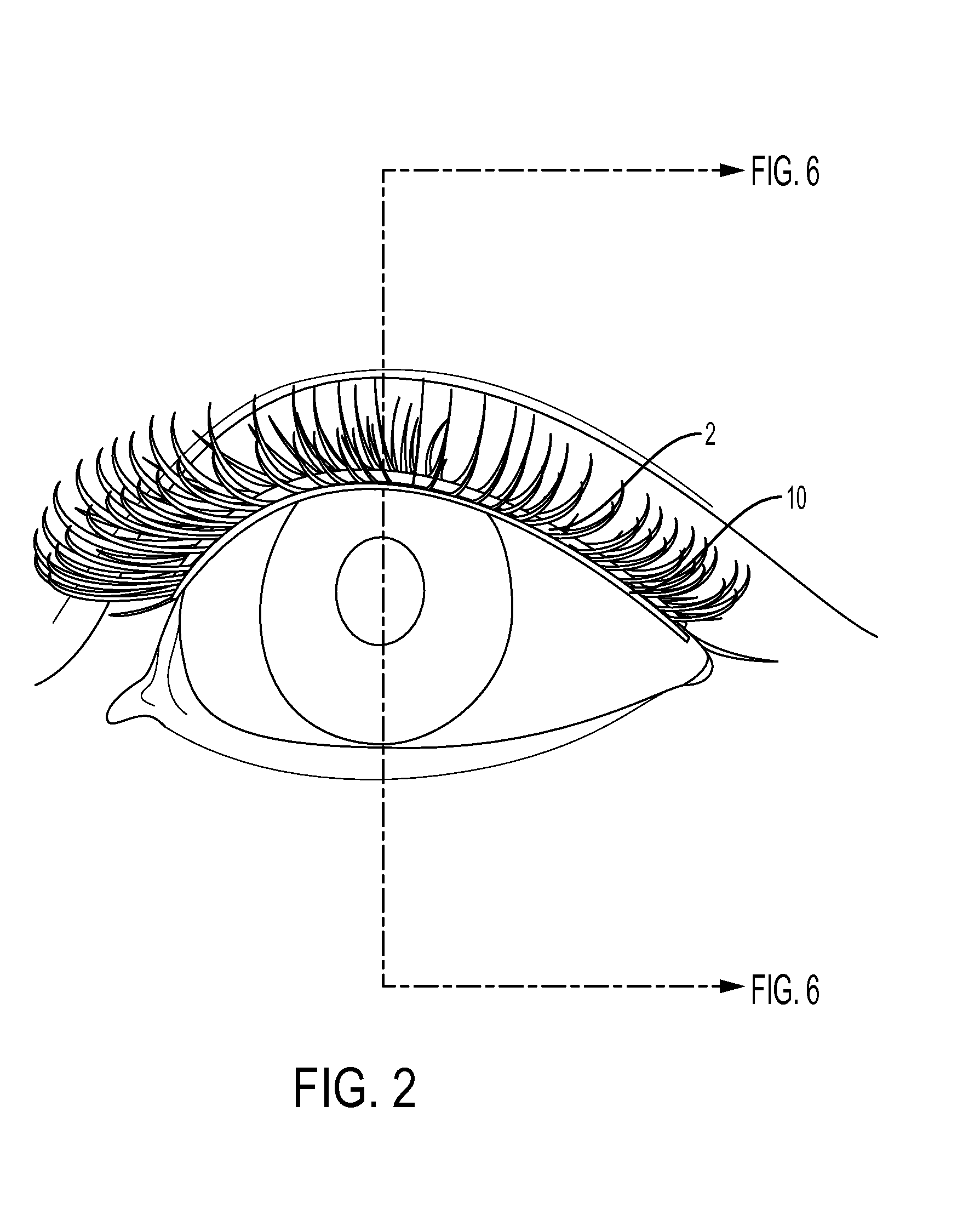

[0029]FIG. 2 shows the upper and lower eyelash assemblies (2,10) magnetically engaged with each other and installed on the wearer's upper eyelash (6). The assemblies are retained on the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com