Track-module bogie-suspension system

a bogie suspension and track module technology, applied in the field of track modules, can solve the problem that none of the prior art systems includes all elements, and achieve the effects of reducing contact forces, reducing load per axle, and high load-supporting capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

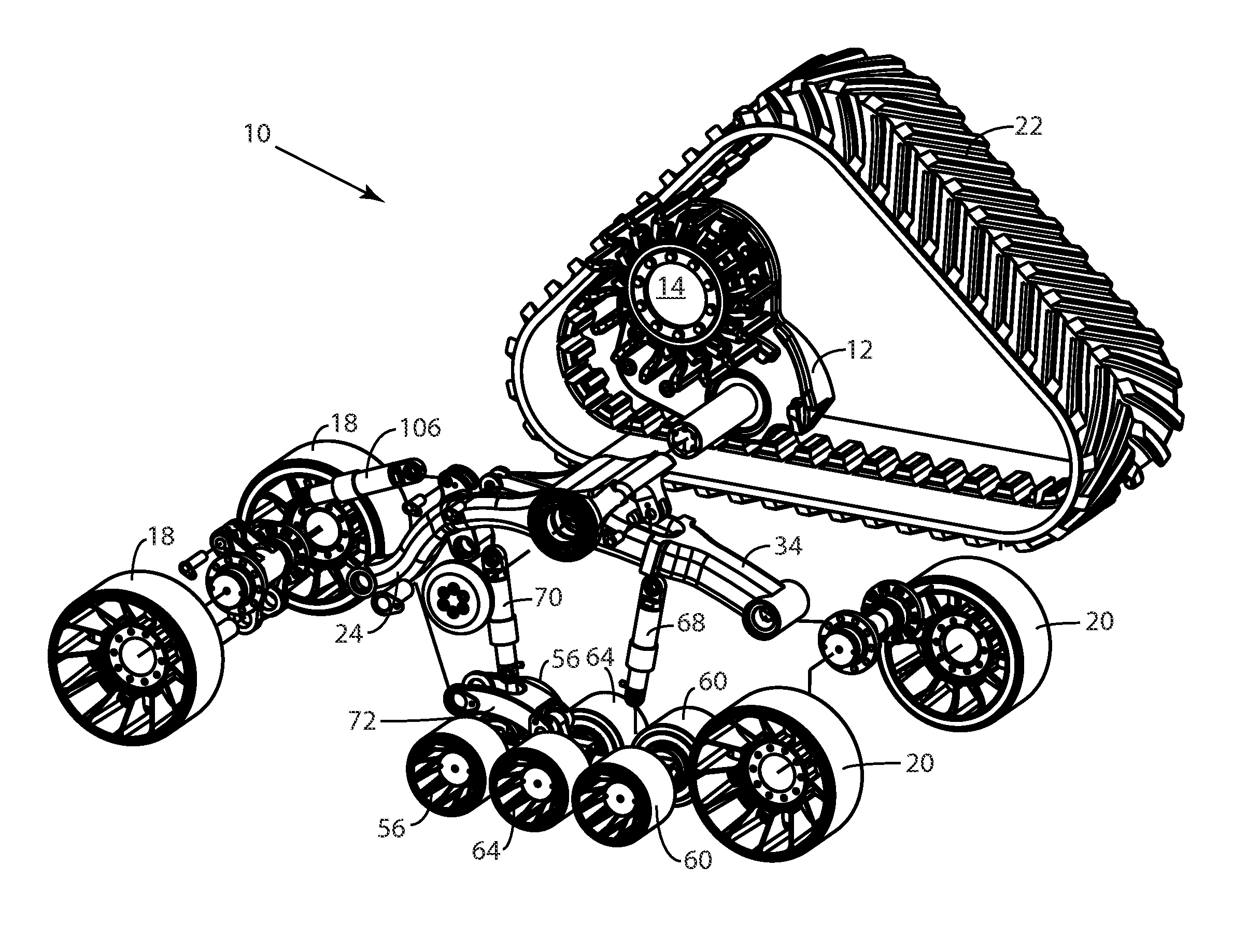

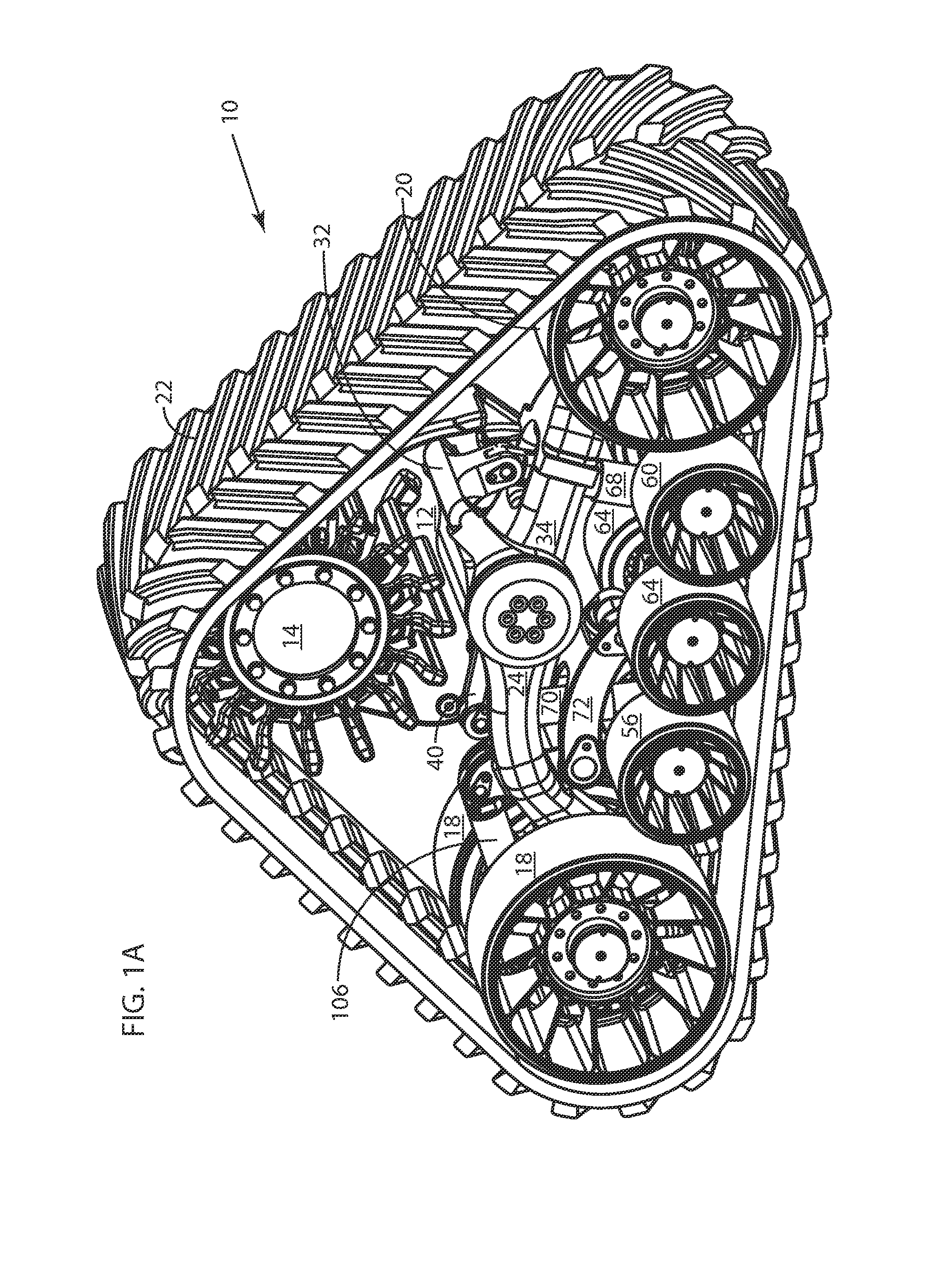

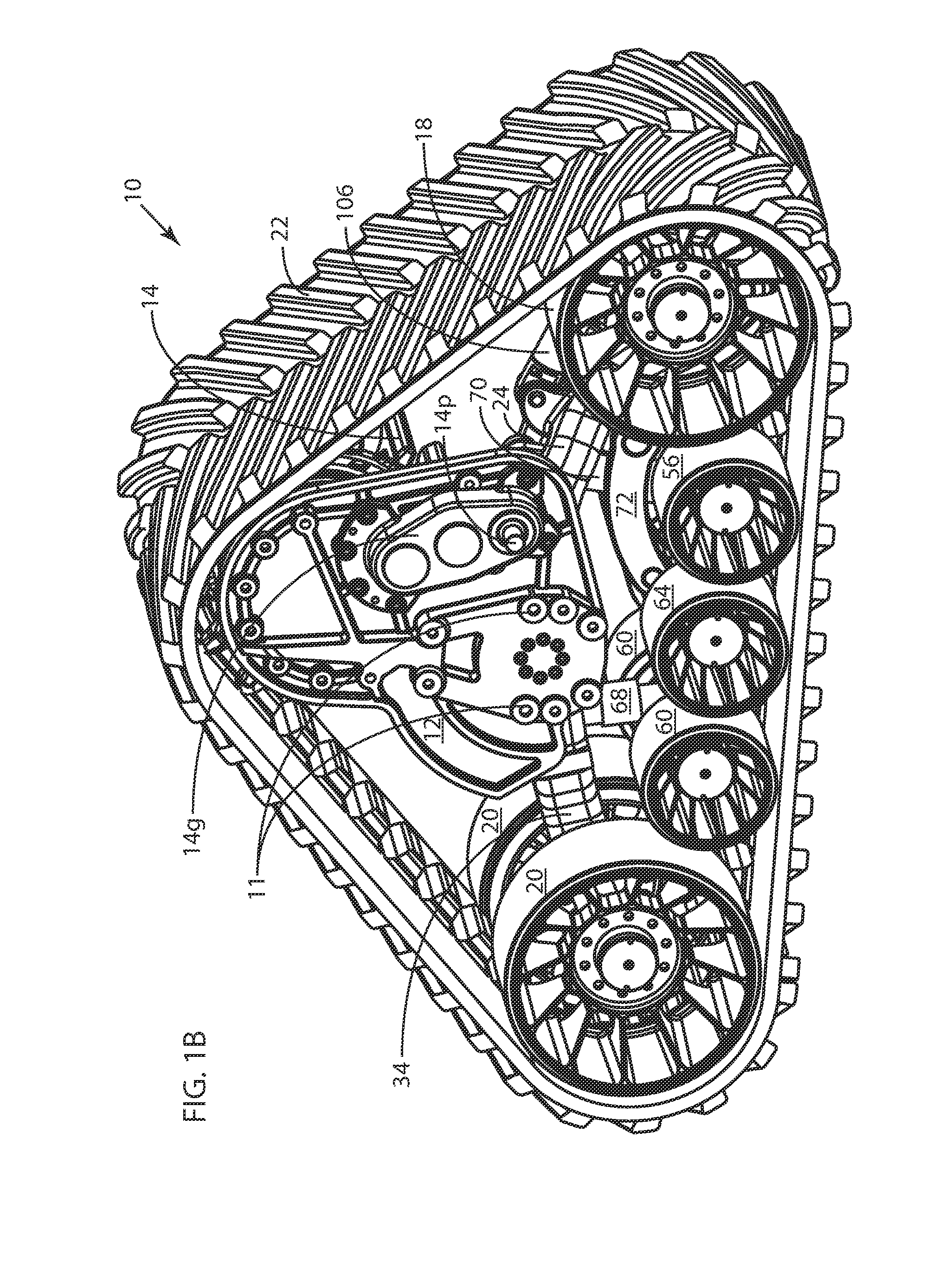

embodiment 10

[0064]Bogie wheels 56 are leading bogie wheels, bogie wheels 60 are trailing bogie wheels, and bogie wheels 64 are middle bogie wheels. Bogie wheels 56, 60 and 64 are part of a bogie assembly 46. Embodiment 10 also includes a leading suspension arm 24, a trailing suspension arm 34, a leading suspension element 68, a trailing suspension element 70, and a tensioning element 106. Leading suspension element 68 includes upper end 68U and a lower end 68L, and trailing suspension element 70 includes an upper end 70U and a lower end 70L. The upper-end and lower-end nomenclature and reference number usage is specifically shown in FIGS. 4 and 18-19 and discussed with respect to the embodiment of FIGS. 18-19.

[0065]The direction of forward travel of the track module of embodiment 10 (and other similar embodiments presented herein) is defined by leading idler wheels 18 being ahead of trailing idler wheels 20. FIG. 4 includes an arrow 122 indicating the direction of travel applicable to all embod...

embodiment 200

[0107]Track-module embodiment 200 differs from all of the previously-described embodiments of track-module apparatus in that movements of leading suspension element upper end 68U at first suspension joint 82p and trailing suspension element upper end 70U at second suspension joint 86p are interdependent. Such interdependence is brought about by track-module apparatus 200 including unitary leading and trailing idler arms 202 (unitary structure 202). The unitary character of such arm structure is indicated by reference number 202 on both leading and trailing portions of unitary structure 202. As best seen in FIG. 18, the leading and trailing portions of the unitary structure 202 are rigidly connected to form a single structure with leading and trailing portions rotatably attached to frame 12 at suspension-arm axis 44. Since first suspension joint 82p and second suspension joint 86p are on opposite sides of unitary structure 202 with respect to suspension arm axis 44, upward movement o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com