After market installable closed loop humidifier system and kit utilizing high efficiency furnace condensate water or city water inlet for humidifying an enclosed space

a closed-loop humidifier and open-loop technology, which is applied in air humidification systems, lighting and heating apparatus, heating types, etc., can solve the problems of wasting ninety-two percent of the provided water, and wasting twenty-four gallons of water. , to achieve the effect of reducing water and sewer costs, reducing power requirements, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]As previously described, the present invention provides a retrofit kit and assembly for use with an existing furnace / humidifier installation. In particular, the present invention provides closed loop and recyclable resupply of a volume of water to the furnace mounted humidifier for providing humidification of an internal space.

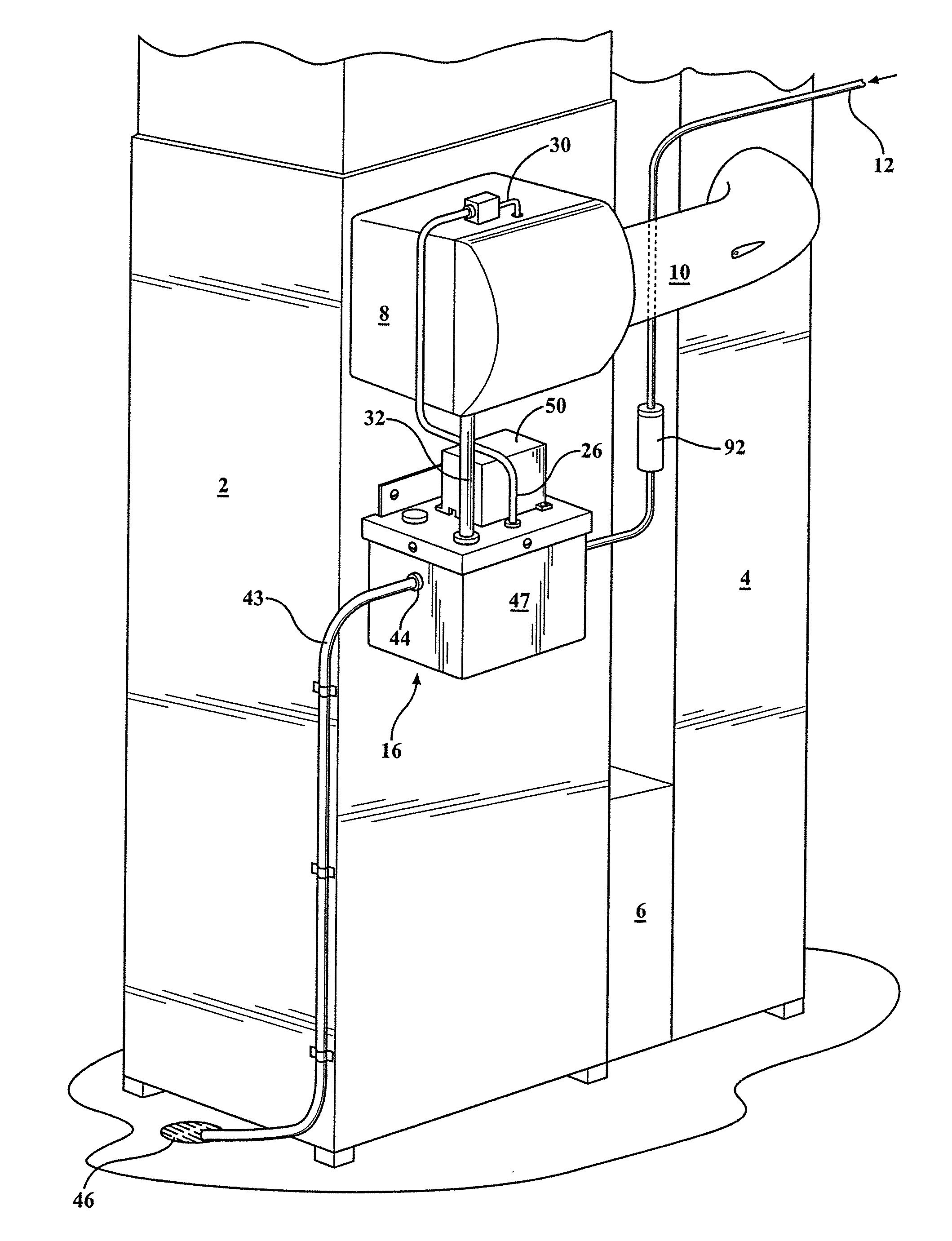

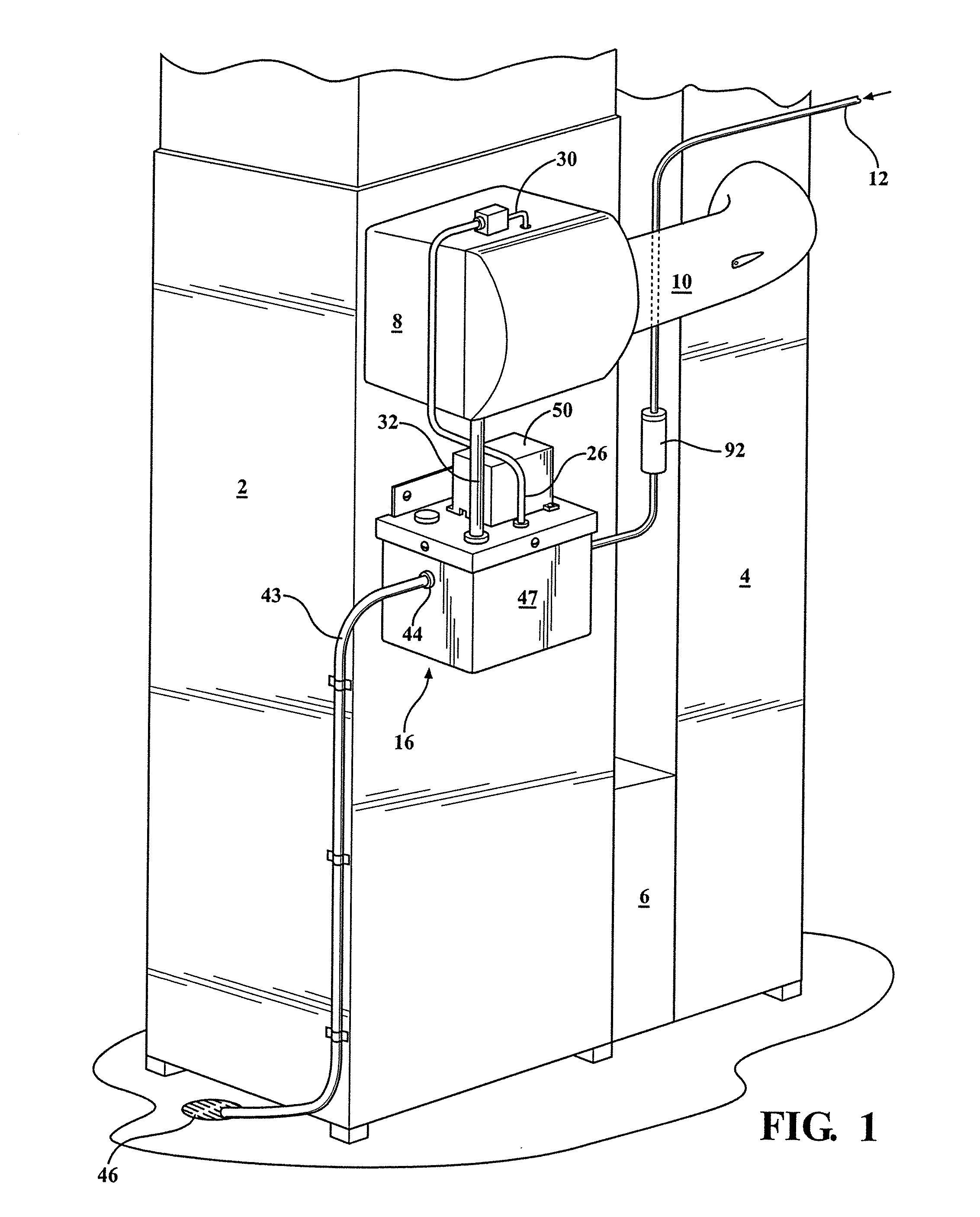

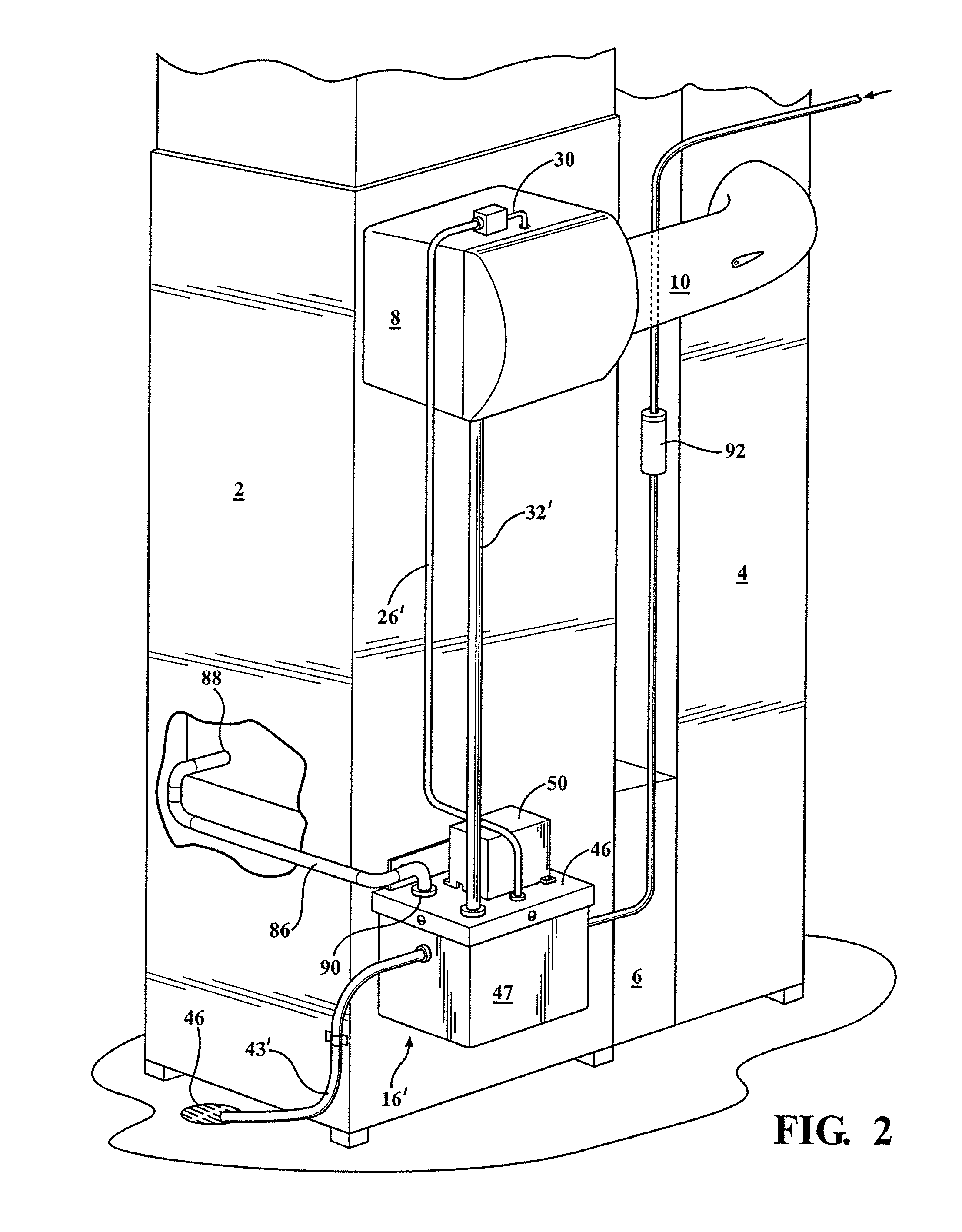

[0026]As will be subsequently described with reference to illustrations, the closed loop system can primarily (typically exclusively) operate using the aqueous condensate outlet generated by the normal operation of a high efficiently furnace (this generally represented by three dimensional housing 2 connected to a heated air exhaust 4 via an electrostatic cleaner assembly 6). Also depicted at 8 is a humidifier assembly mounted to an exterior location of the furnace housing and for providing a humidified airflow into the furnace housing 2 for combination with the furnace airflow.

[0027]Viewing FIGS. 1 and 4 in combination, a first variant of the closed loo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com