Systems and methods for active particle separation

a technology of active particle and filter, applied in magnetic separation, enzymology, instruments, etc., can solve the problem of increasing the pressure drop across the filter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

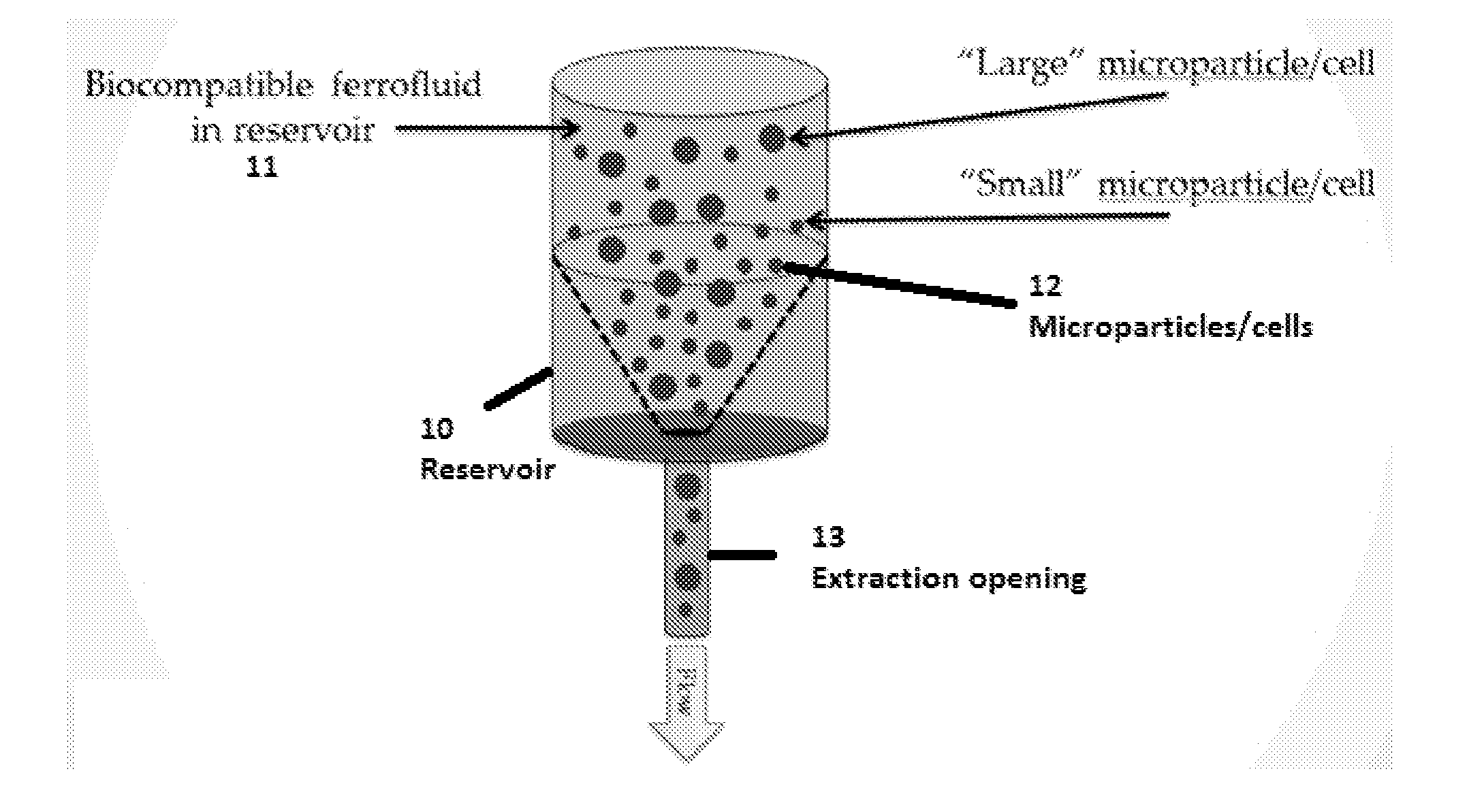

[0063]As shown in FIG. 1, a reservoir 10 containing a ferrofluid 11 (which in some embodiments is biocompatible) and a mixture of microparticles / cells 12 having different sizes (in some embodiments). In FIG. 1, no external forces are applied to the fluid, reservoir and / or particles, and ignoring buoyancy issues, a random mixture of particles may flow through an extraction opening 13 of the reservoir.

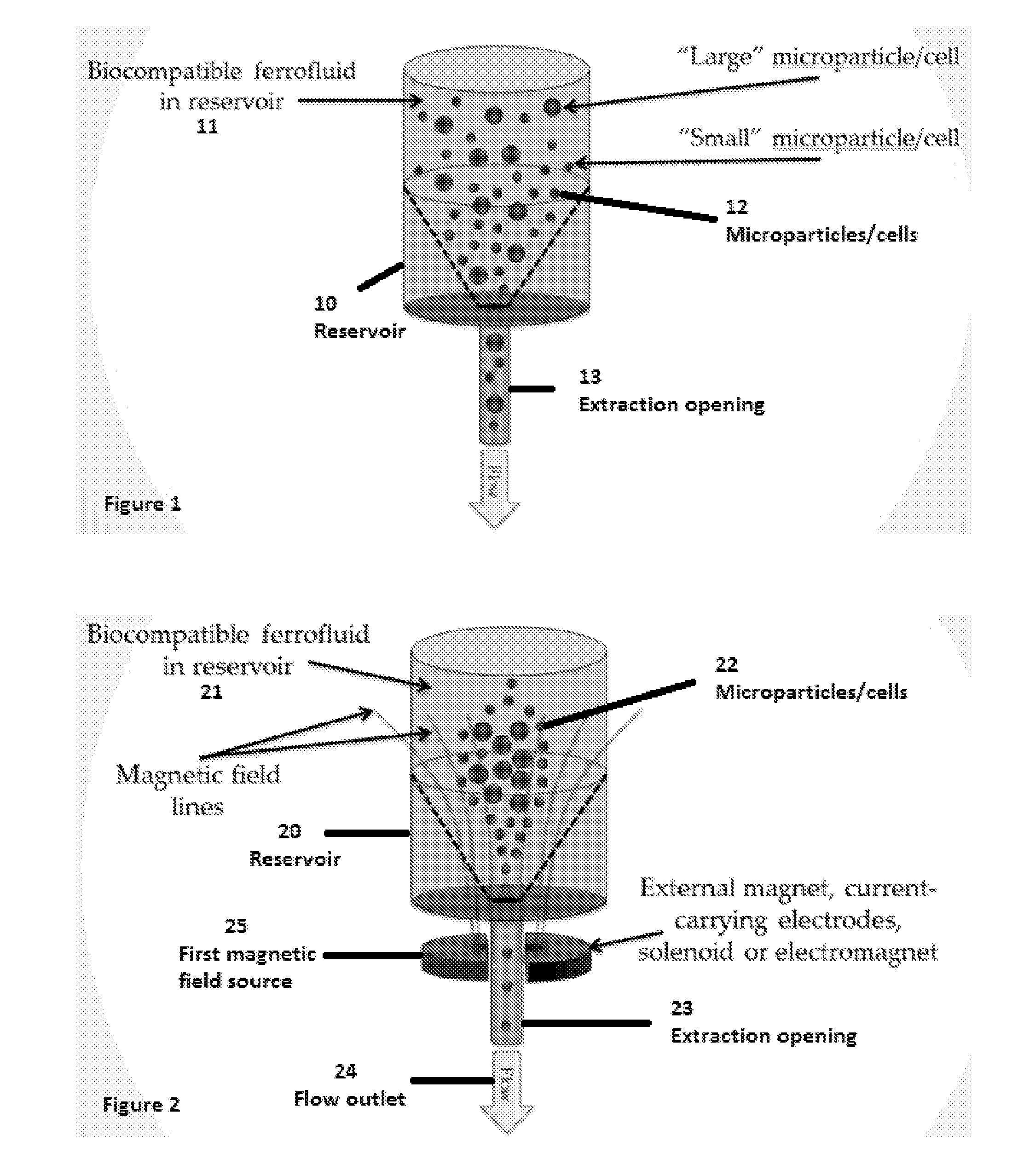

[0064]FIG. 2 illustrates some embodiments, where a reservoir 20 containing a ferrofluid 21 with a mixture of microparticles 22 of different sizes, and includes at least one magnetic source 25 for applying a magnetic field to the ferrofluid 21, which may be arranged either internal or external to the reservoir 20. The particles 22 include biological cells and moieties. The magnetic field may be configured to exert one or more forces on the ferrofluid 21 and may be generated via, for example, one or more: external magnets, current-carrying electrodes, solenoid, and electromagnets. In one e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore sizes | aaaaa | aaaaa |

| pore sizes | aaaaa | aaaaa |

| pore sizes | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com