Aircraft structure and method of manufacture

a technology of aircraft and manufacturing methods, applied in the direction of air braking surfaces, wing adjustments, aircraft assembly, etc., can solve the problems of high manufacturing cost, large number of bespoke parts required, and difficult assembly of moving aerodynamic aircraft structures, etc., to achieve easy assembly, improve structural efficiency, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

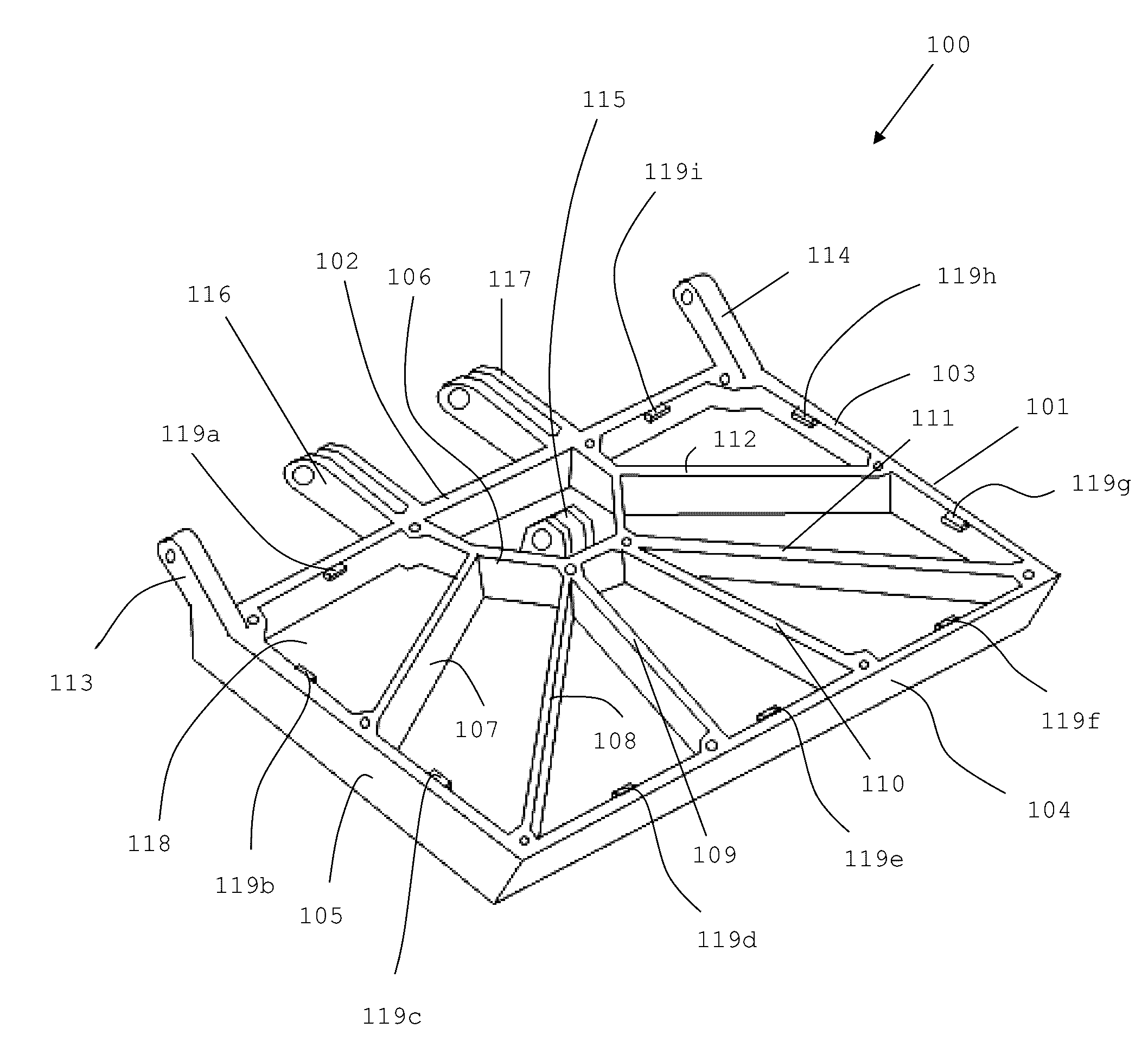

[0047]FIG. 1 shows a perspective view of a common structural module 100 for part of a spoiler. The common structural module 100 is intended to be used for all spoilers on an aircraft, with each spoiler having a different surface component (described later) attached to the common structural module 100.

[0048]The common structural module 100 comprises a rectangular box frame 101 with two short sides 103, 105 and two long sides 102, 104. Along the middle of one of the long sides 102 is a semi-circular frame 106 inside the box frame 101.

[0049]There are six struts 107, 108, 109, 110, 111, 112 radiating out from the semi-circular frame 106 to the insides of the sides 103, 104, 105 of the box frame 101. First strut 107 extends to approximately halfway along short side 105, second strut 108 extends to the corner of short side 105 and long side 104, third strut 109 extends to approximately a quarter of the way along the length of long side 104 from the corner with short side 105, fourth strut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com