Self-Removing Plug for Pressure Isolation in Tubing of Well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

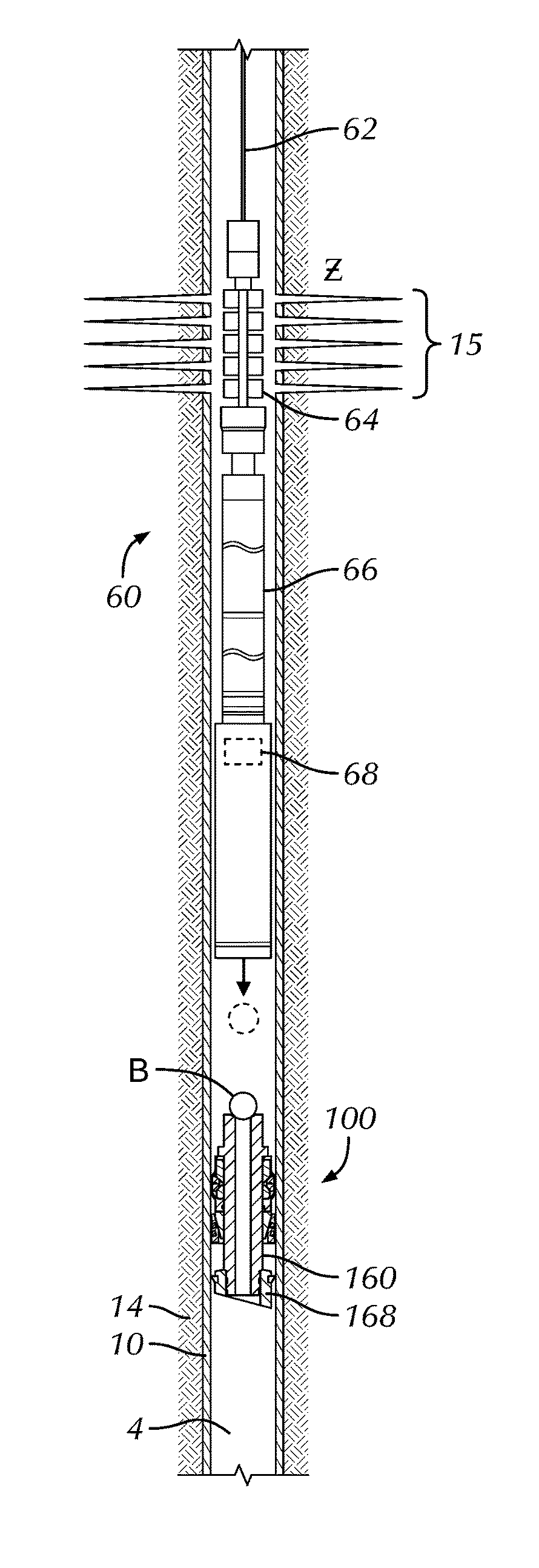

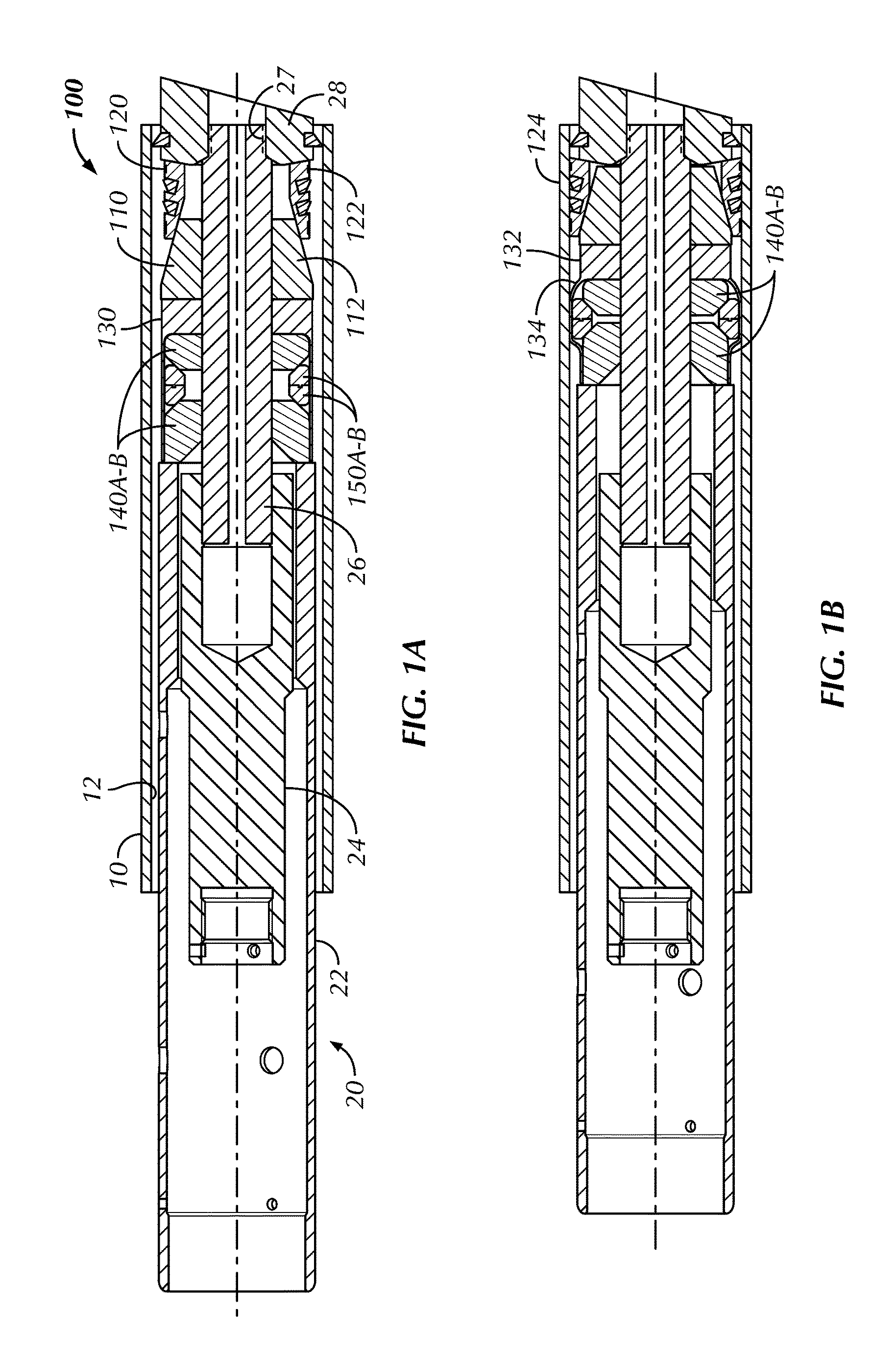

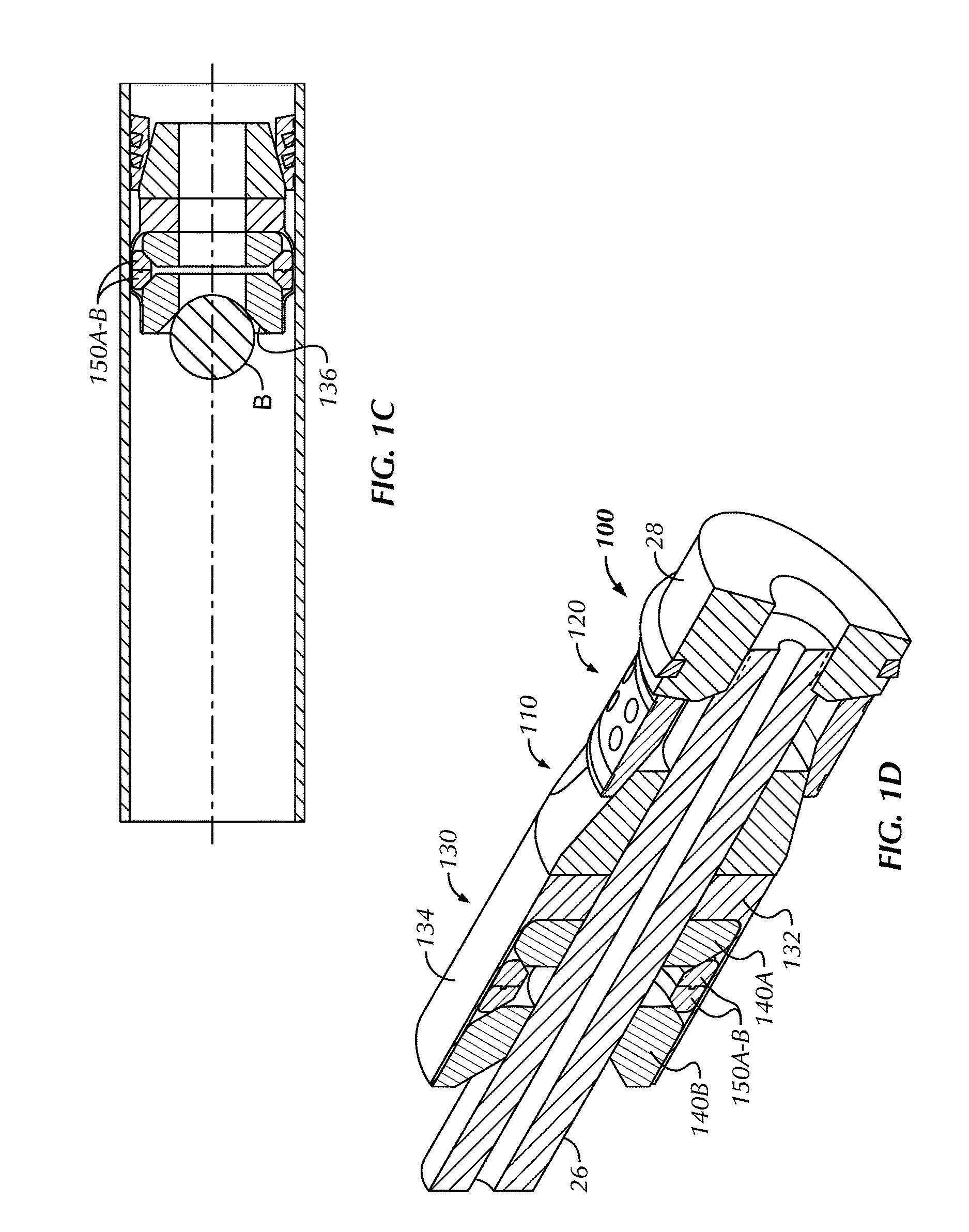

[0067]FIGS. 1A-1C illustrate cross-sectional views of a first self-removing plug 100 according to the present disclosure during stages of setting in tubing, such as cemented casing 10. FIG. 1D illustrates a perspective view of the first self-removing plug 100 in cross-section. The plug 100 includes a cone 110, a slip 120, and a seal element (having a sealing sleeve or sheath 130, body rings 140A-B, and expansion element or rings 150A-B).

[0068]This plug 100 (as well as the other plugs disclosed herein) is self-removing. For example, the various components of this plug 100 and the others disclosed herein can be composed of a dissolvable material. In one embodiment, such a dissolvable material can include a reactive metal, such as a magnesium alloy. One particular magnesium alloy is SoluMag™ available from Magnesium Elektron Alloys. Other reactive metals, such as calcium, magnesium, aluminum, can be used and can include alloying elements of calcium, magnesium, aluminum, lithium, galliu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com