An aluminum alloy and the preparation process thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

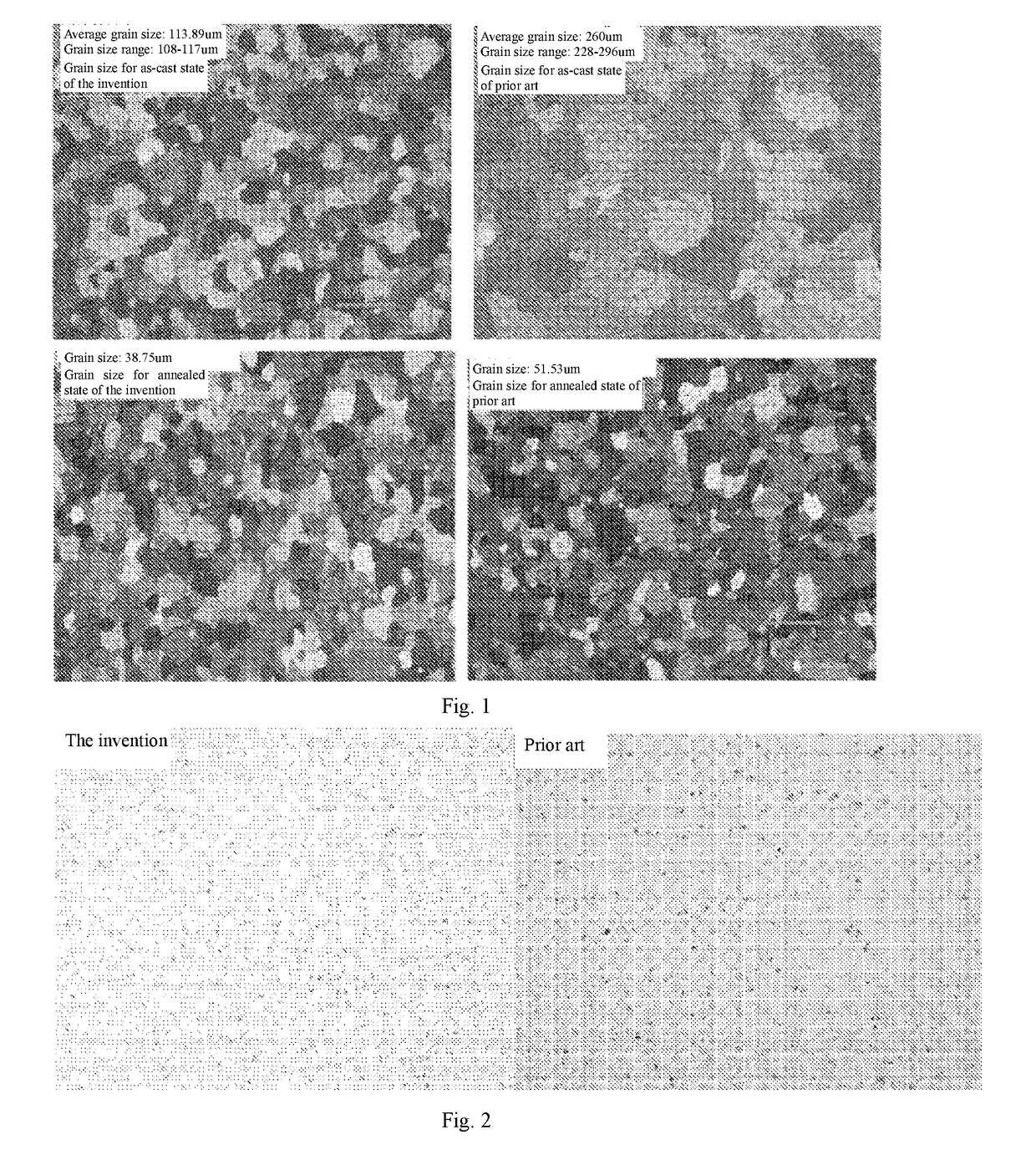

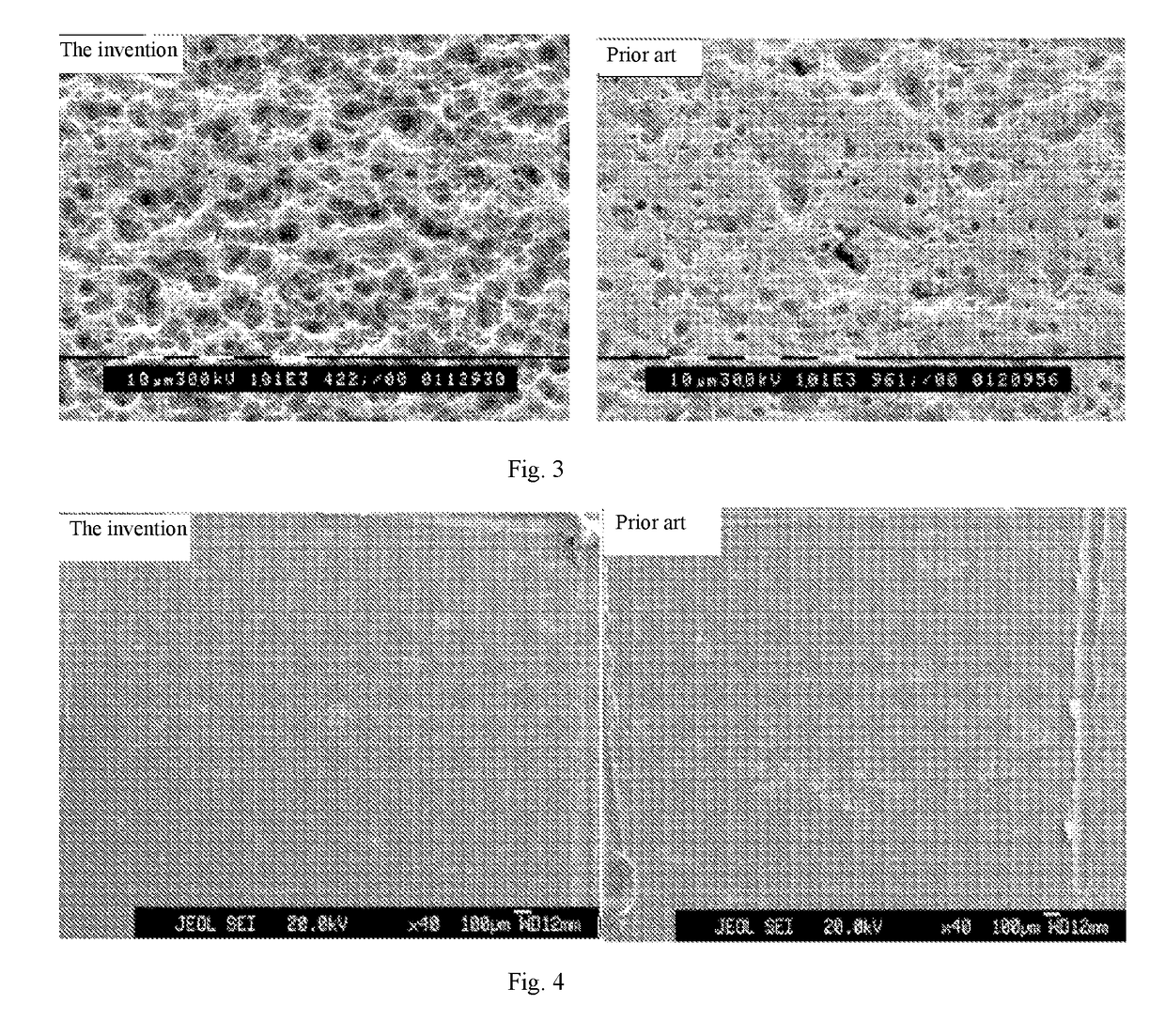

Method used

Image

Examples

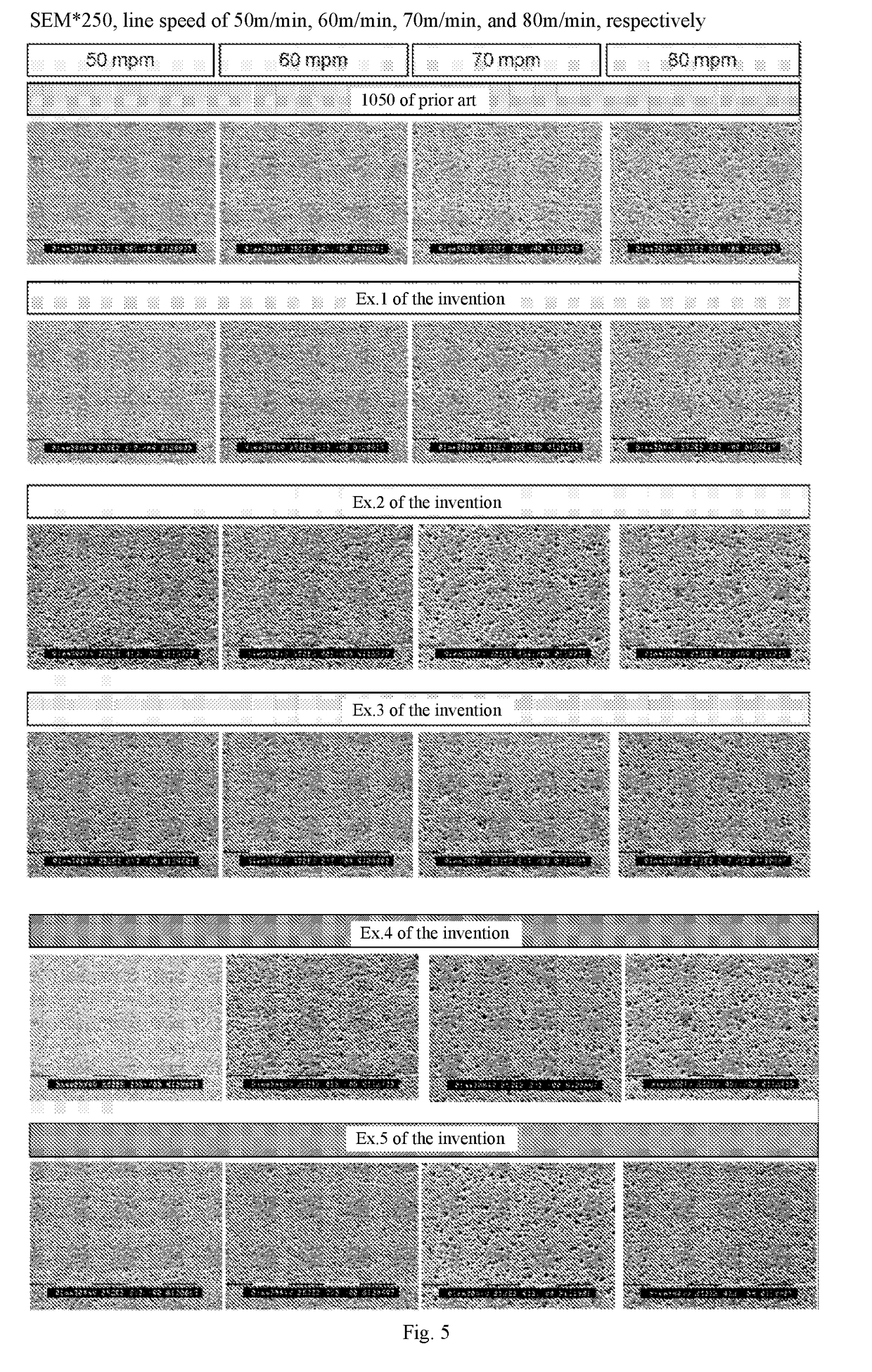

example 1

[0088]An aluminium alloy strip according to the present invention was produced according to the process illustrated below, referring to the example formulation as shown in Table 1:[0089](1) providing materials of: 108000 kg of 99.7 aluminium ingot (containing 40 kg of Si, 194 kg of Fe, 1.1 kg of Mg, 0.5 kg of Cu), 15 kg of AlSi20 alloy, 230 kg of 80Fe agent, 63.5 kg of Mg ingot, and 7.6 kg of AlCu50 alloy; adding into a remelting furnace having a remelting temperature of 750 degrees centigrade, refining, inclusion removing, stirring, and analyzing and regulating the components, the composition listed in Table 1, adding into a stewing furnace, stewing, refining, degassing, inclusion removing, adding Al-5Ti-1B rods (1.2˜1.4 kg / t molten aluminium) and casting into a cast ingot in a casting machine at a casting temperature of 705 degrees centigrade;[0090](2) controlling the holding temperature for hot rolling at 580 degrees centigrade, for holding the metal for 2 hours;[0091](3) hot rol...

example 2

[0095]An aluminium alloy strip according to the present invention was produced according to the process illustrated below, referring to the example formulation as shown in Table 1:[0096](1) providing materials of: 104000 kg of 99.7 aluminium ingot (containing 52 kg of Si, 198 kg of Fe, 1.5 kg of Mg), 156 kg of AlSi20 alloy, 220 kg of 80Fe agent, 102 kg of Mg ingot, and 8.3 kg of AlCu50 alloy; adding into a remelting furnace having a remelting temperature of 750 degrees centigrade, refining, inclusion removing, stirring, and analyzing and regulating the components, the composition listed in Table 1, adding into a stewing furnace, stewing, refining, degassing, inclusion removing, adding Al-5Ti-1B wires (1.2˜1.4 kg / t molten aluminium) and casting into a cast ingot in a casting machine at a casting temperature of 705 degrees centigrade;[0097](2) controlling the holding temperature for hot rolling at 550 degrees centigrade, for holding the metal for 2 hours;[0098](3) hot rolling with an ...

example 3

[0102]An aluminium alloy strip according to the present invention was produced according to the process illustrated below, referring to the example formulation as shown in Table 1:[0103](1) providing materials of: 116000 kg of 99.7 aluminium ingot (containing 58 kg of Si, 224 kg of Fe, 1.2 kg of Mg, 1.6 kg of Cu), 116 kg of AlSi20 alloy, 184 kg of 80Fe agent, 91.6 kg of Mg ingot, and 15.3 kg of AlCu50 alloy; adding into a remelting furnace having a remelting temperature of 770 degrees centigrade, refining, inclusion removing, stirring, and analyzing and regulating the components, the composition listed in Table 1, adding into a stewing furnace, stewing, refining, degassing, inclusion removing, adding Al-5Ti-1B wires (1.2˜1.4 kg / t molten aluminium) and casting into a cast ingot in a casting machine at a casting temperature of 720 degrees centigrade;[0104](2) controlling the holding temperature for hot rolling at 520 degrees centigrade, for holding the metal for 4 hours;[0105](3) hot ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap