Image forming method

a technology of image forming and seal base material, which is applied in the directions of duplicating/marking methods, thermography, printing, etc., can solve the problems of insufficient study of aspects, the difficulty of gluing the seal base material on the transfer image-receiving material without crinkling,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0069]Next, the present invention will be described in more detail by way of examples.

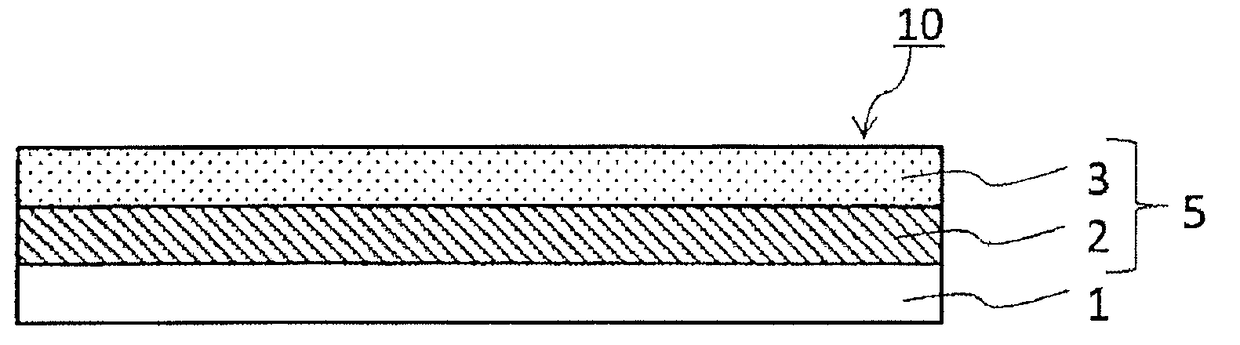

[0070]As a release sheet, a polyethylene terephthalate film having a thickness of 100 μm was used, an adhesive layer having a thickness of 25 μm and a seal base material containing the film shown in the following Table 1 were provided in this order on the release sheet. By repeating this procedure, the decorative seals of Examples 1 to 10 and Comparative Examples 1 to 3 were prepared. The elongation percentage in the table is the elongation percentage determined by the test method in conformity with JIS-K-7127: 1999.

TABLE 1FilmElongationMaterialpercentageThicknessExample 1Polyvinyl187%50 μmchlorideExample 2Polyvinyl208%50 μmchlorideExample 3Polyvinyl225%50 μmchlorideExample 4Polyvinyl255%50 μmchlorideExample 5Polyvinyl150%50 μmchlorideExample 6Polyvinyl400%50 μmchlorideExample 7Polyvinyl225%20 μmchlorideExample 8Polyvinyl225%60 μmchlorideExample 9Polyvinyl225%100 μm chlorideExample 10Polyvinyl225%1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation percentage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com