Dyeing method of denim yarns and fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

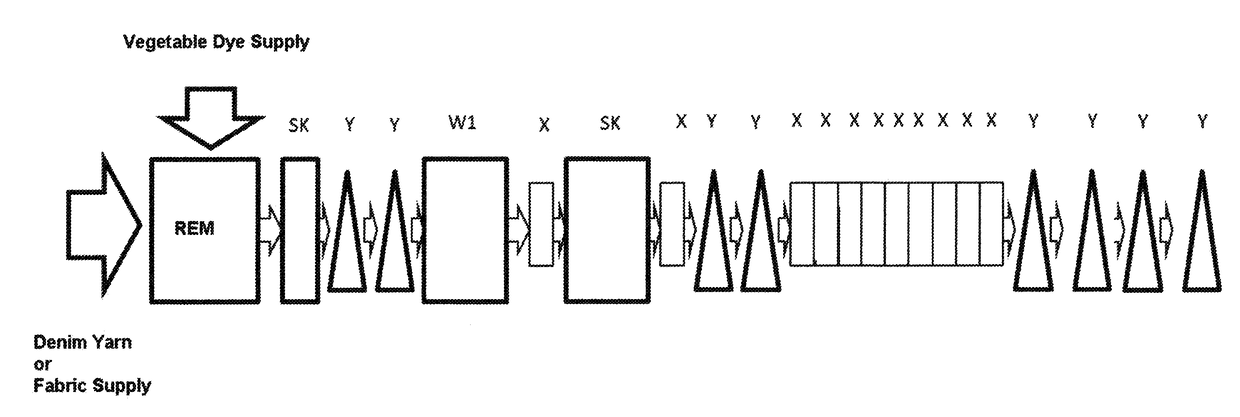

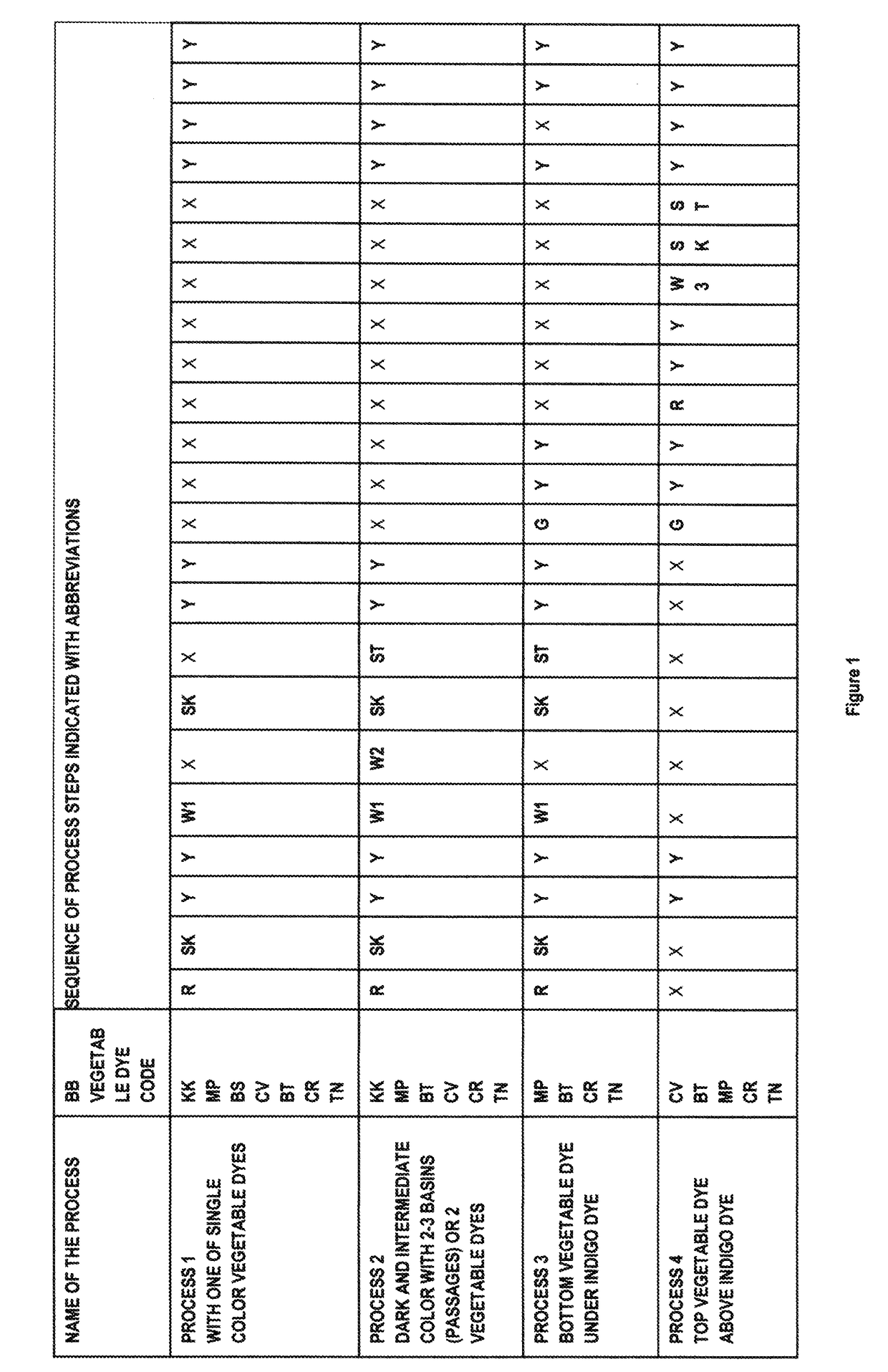

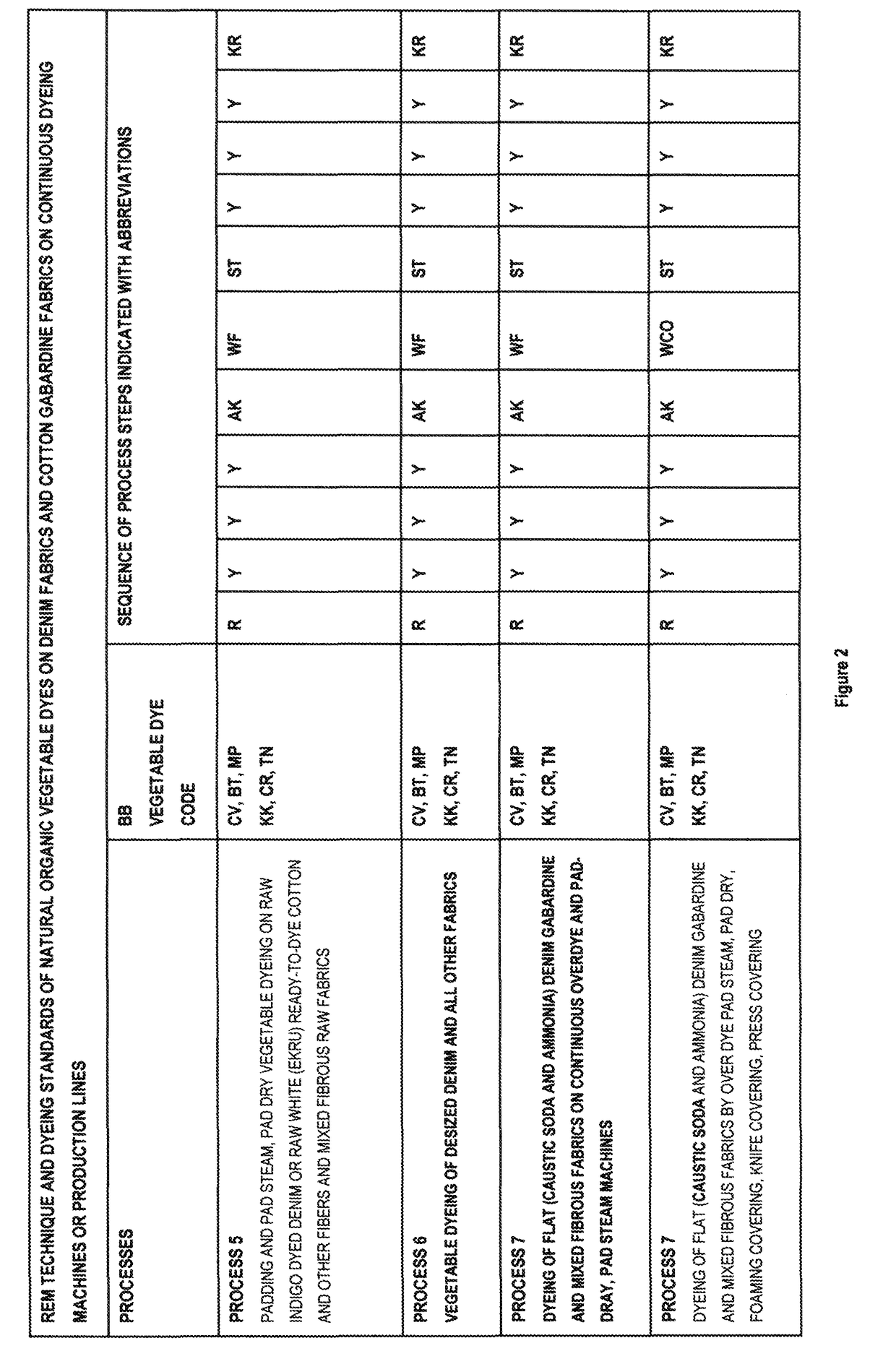

[0098]In order to provide a better understanding of the production process according to the present invention, it will be referred to the prior art. According to the prior art, cotton fiber is a vegetable natural fiber and cannot form stable bonds by reacting with vegetable dyes. In order to eliminate this drawback, the so-called REM technique is carried out prior to vegetable dyeing process. The process step designated as REM or “R”, allows to increase the distance (gap) between the fibers and to provide a catalyst effect in the binding reaction between the dye molecules and the cotton molecules so that the dyeing efficiency is increased at least three fold. The development of this technique, in turn, paved the way to use vegetable dyes in mass production with competitive costs and qualities. Here below, both the process steps, and the raw materials (or materials) used in the process will be referred to with abbreviations.

[0099]Using this REM technique (R), it is now possible to ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com