Use of a mixture of carbon dioxide and nitrogen as an inerting and flow medium in powder injection systems for pulverized coal gasification under pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

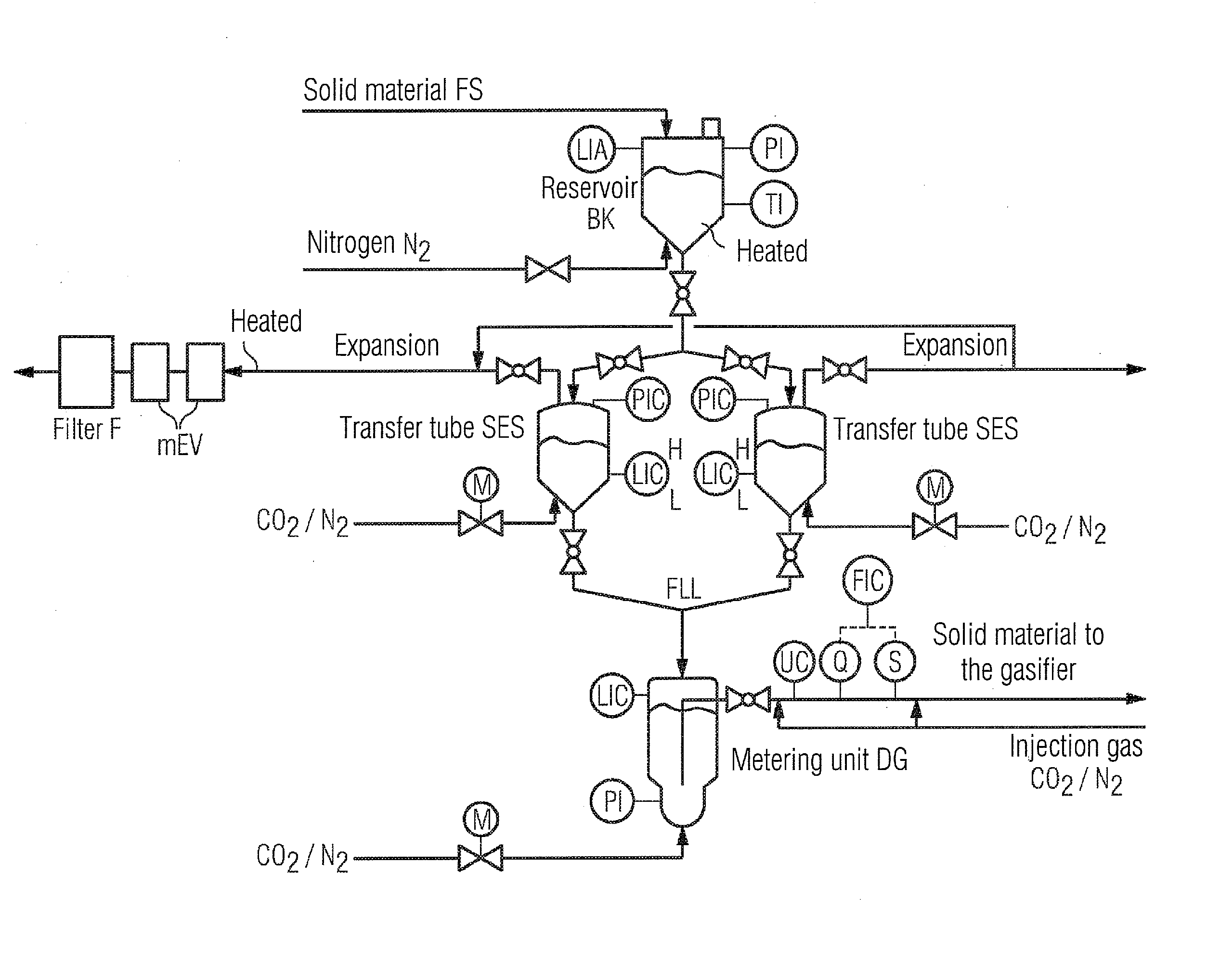

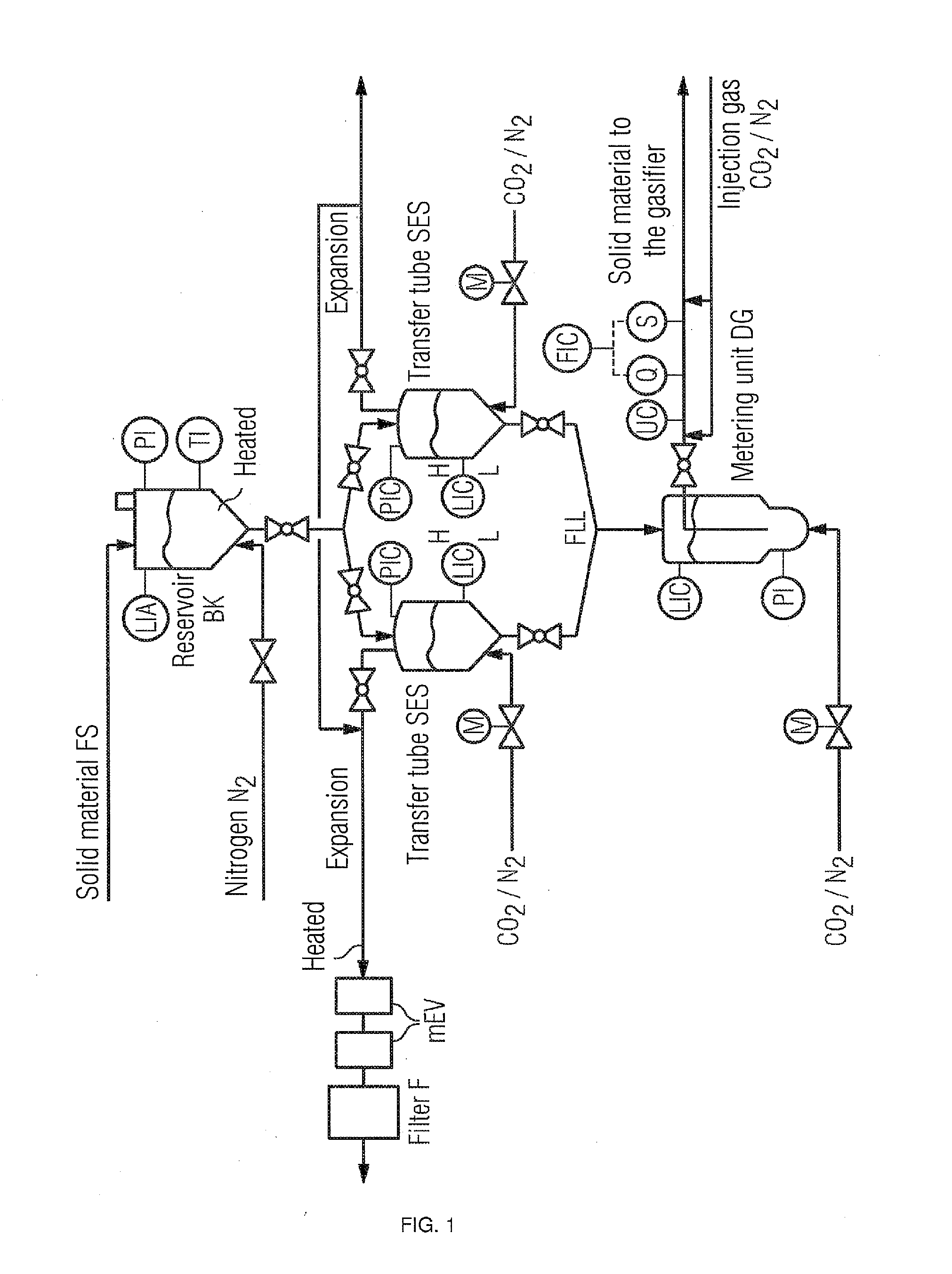

[0011]A reservoir BK under ambient pressure and able to be heated up for supply of solid material FS, such as pulverized coal for example, is able to be supplied with heated nitrogen N2 as an inerting and dispersal medium. The solid material is able to be fed via a flow device to one or more powder injection transfer tubes SES which are at a high operating pressure of for example 40 bar. The powder injection transfer tube is able to be fed a nitrogen N2 / carbon dioxide CO2 mixture as an inerting and flow medium with a temperature above the boundary to the two-phase region at high operating pressure. In the upper area of the powder injection transfer tube the expansion gas is drained away, expanded via a multi-stage pressure relief facility mEV to ambient pressure and dedusted in a following filter F at ambient pressure. The solid material is transferred from the powder injection transfer tubes into the metering vessel DG by gravity flow via a suitably dimensioned downpipe. Between tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com