Absorbent paper product and method for manufacturing such absorbent paper product

a technology of absorbent paper and absorbent fiber, which is applied in the field of absorbent fiber products, can solve the problems of fibrous fibers with a relatively stiff outer appearance, manufacturing costs, negative consumer perception, etc., and achieve the effect of less harmonic and increasing the soft and absorbent perception of users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

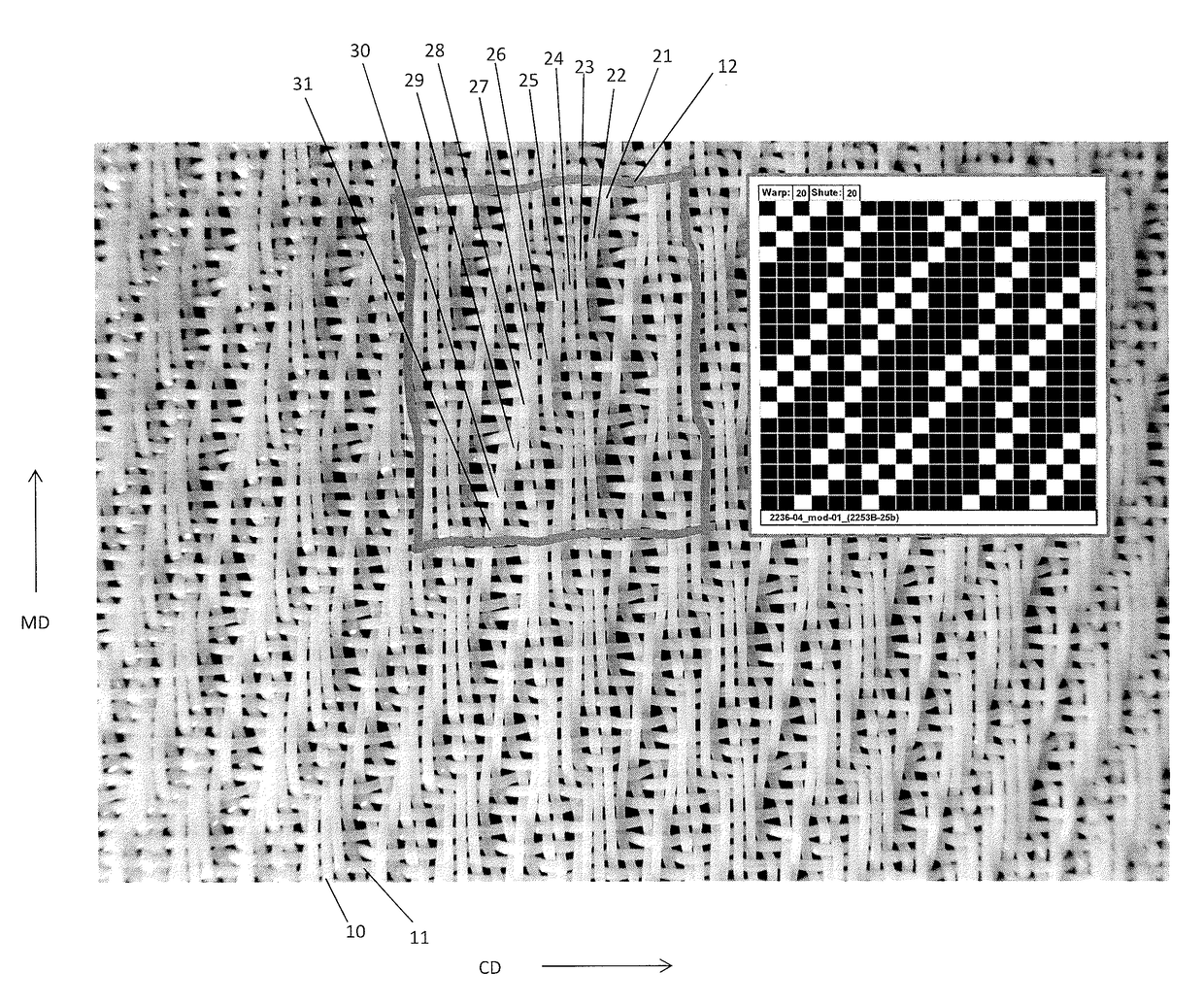

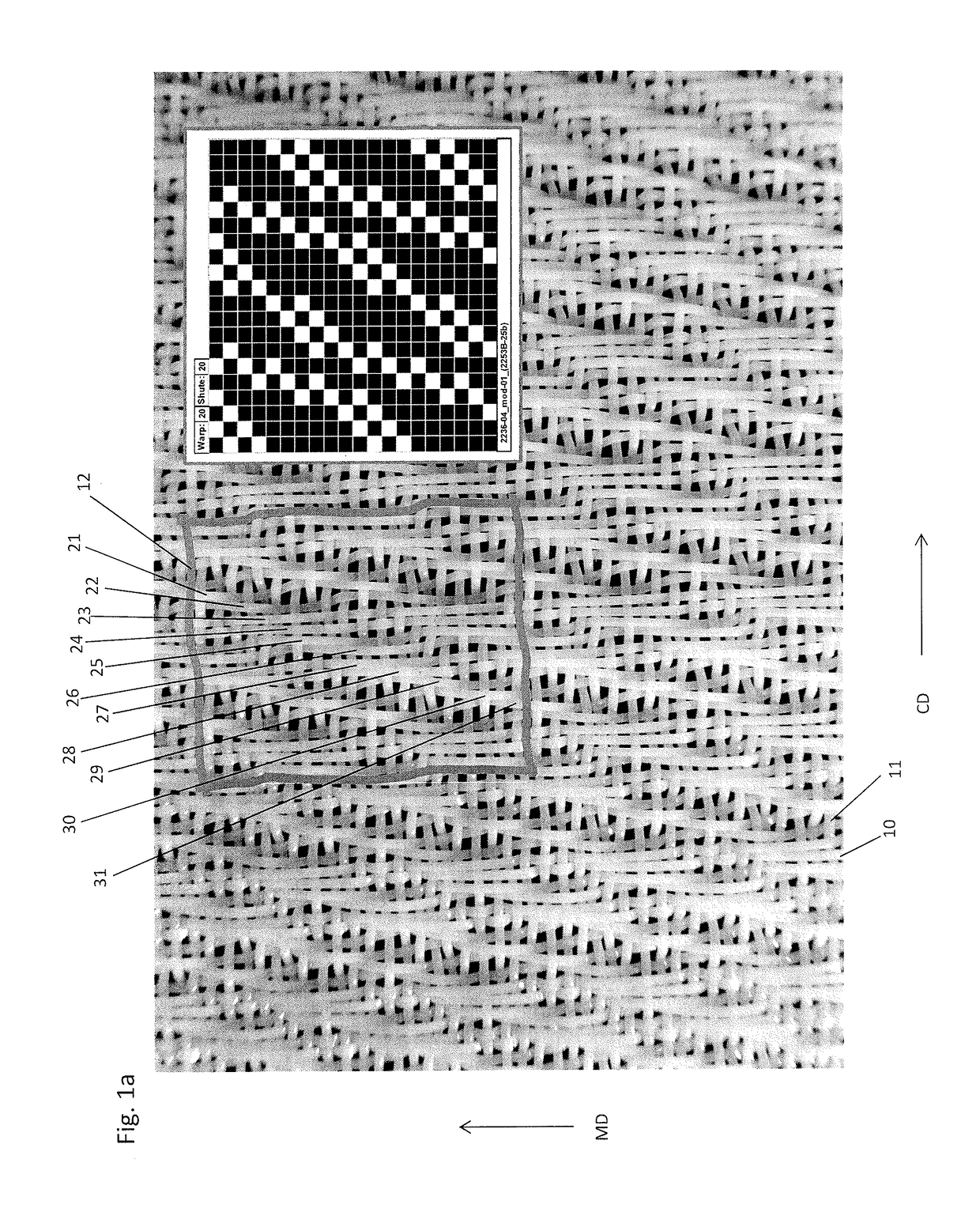

[0076]The fabric, a portion of which is shown in FIG. 1a in a plan view may, according to an embodiment, be a through-air drying fabric. FIG. 1a shows the paper side of the fabric. The fabric is constituted by a plurality of parallel warp yarns 10 extending parallel to the machine direction MD and a plurality of weft yarns 11 substantially extending parallel to the cross-machine direction CD. The warp yarns 10 and the weft yarns 11 are interwoven, wherein warp yarns 10 alternatively float over weft yarns 11 in the machine direction and weft yarns 11 alternatively float over warp yarns 10 in the cross-machine direction. The fabric shown in FIG. 1a has a pattern repeat as indicated by the square 12.

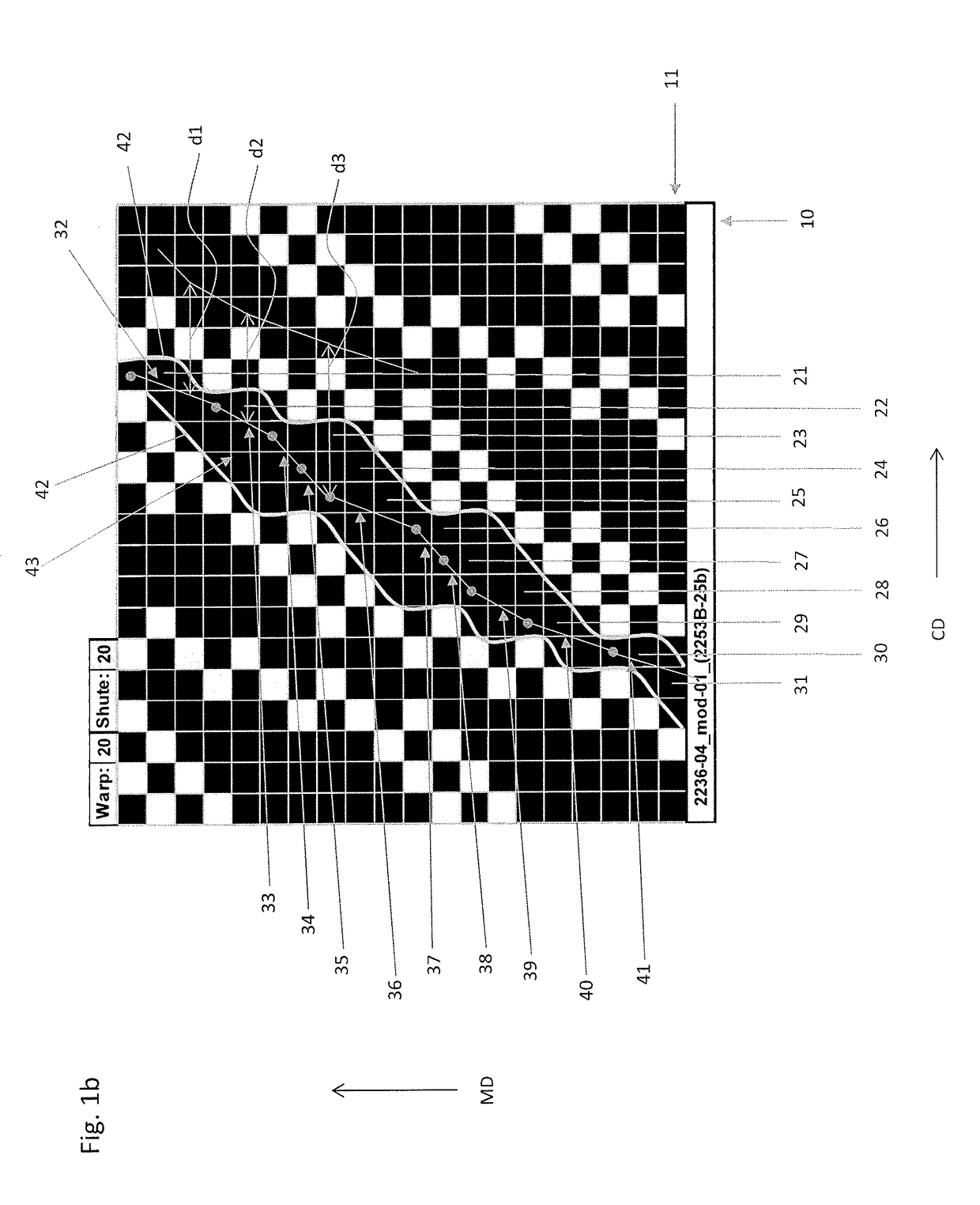

[0077]The pattern repeat 12 includes a first group of warp knuckles 21 to 31. These warp knuckles 21 to 31, which float over a certain number of weft yarns 11 are formed by a plurality of directly adjacent warp yarns 10 with no other warp yarn 10 inbetween. Further, directly adjacent warp k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com