Filter Element of a Filter for Filtering Fluids, and Filter

a filter element and filter fluid technology, applied in the field of filter element of a filter for filtering fluid, can solve the problem of increasing the load limit of the filter element, and achieve the optimal connection of the sides, the optimal shape of the fold, and the optimal load capacity of the filter element.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

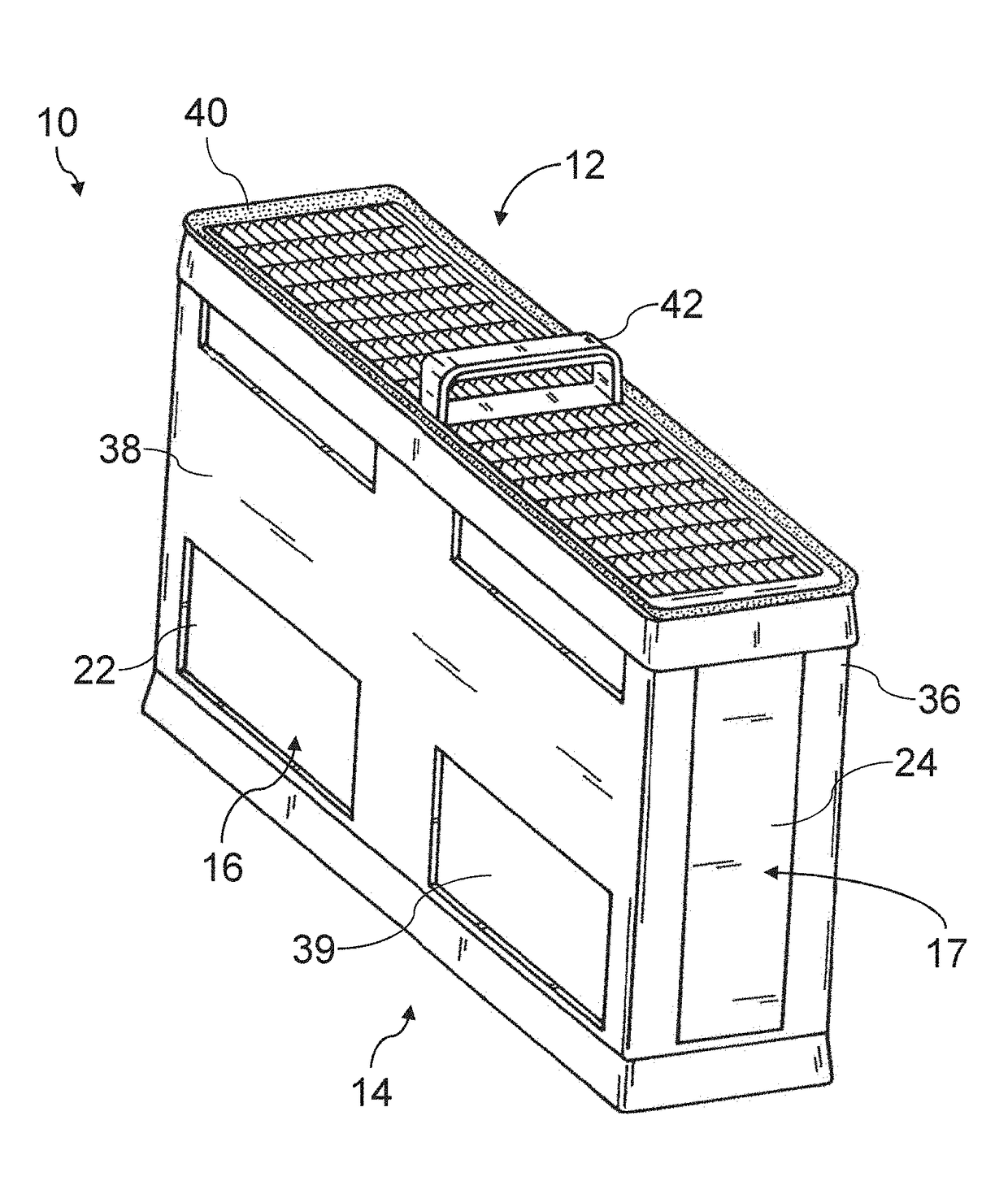

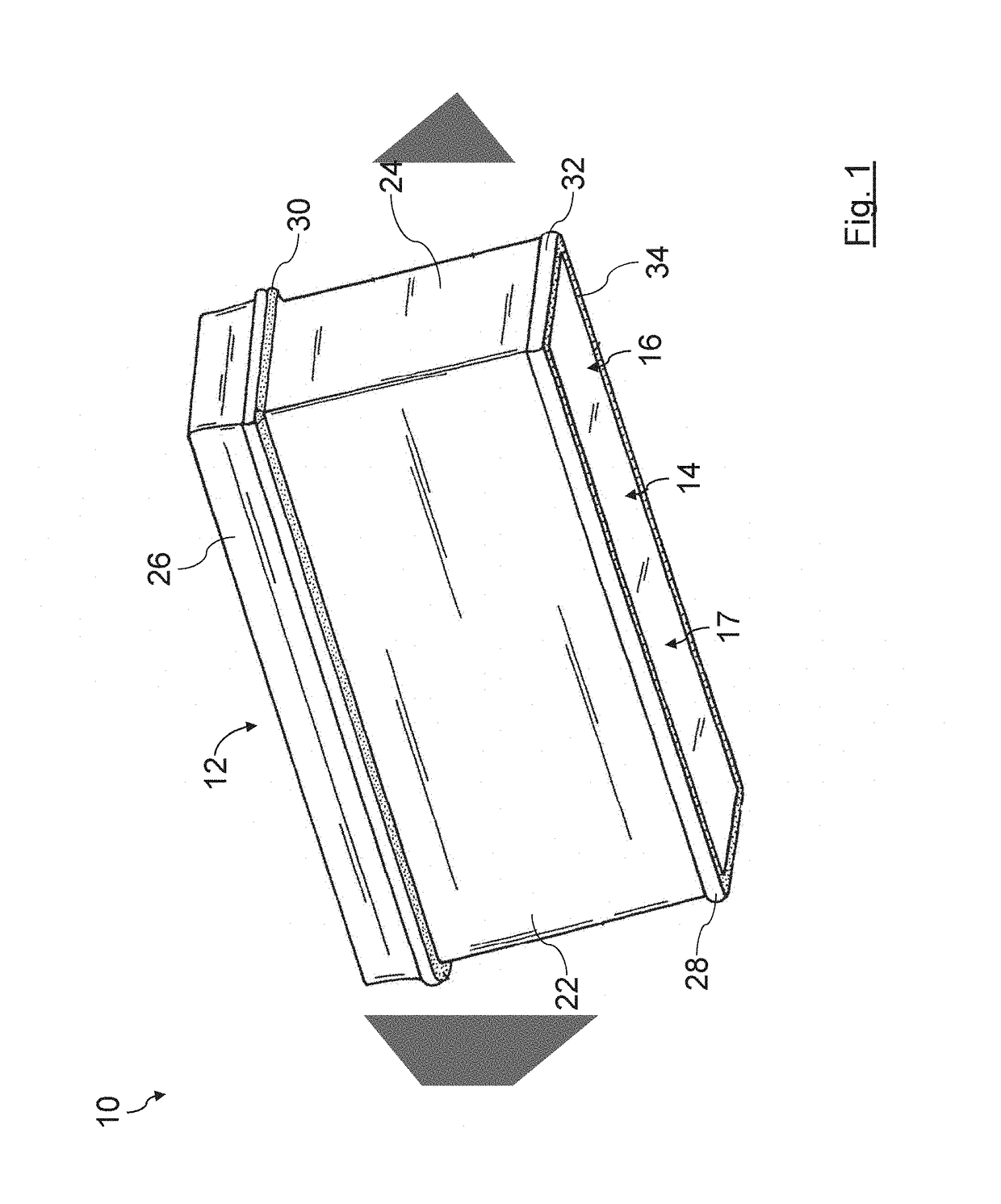

[0033]In FIG. 1, a filter element 10 according to a first embodiment is shown. The filter element can be mounted in a filter housing, not shown, of a filter for a fluid. With the filter element 10 gaseous or liquid fluids can be filtered. For example, such a filter element 10 can be used in an air filter of an internal combustion engine of a motor vehicle.

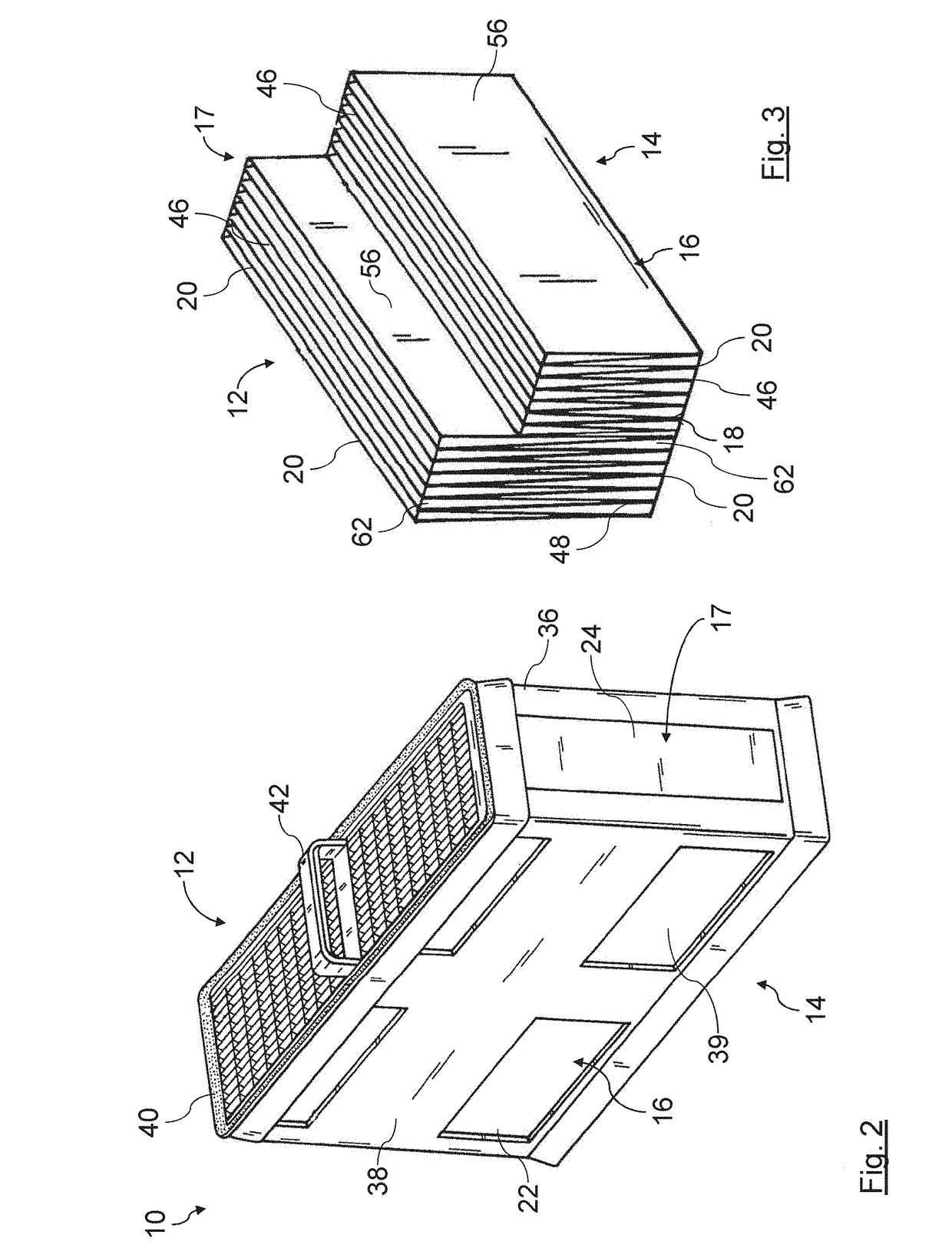

[0034]The filter element 10 has an inflow side 12 at the raw fluid side and an outflow side 14 at the clean fluid side. The filter element 10 comprises a filter bellows 17 of filter medium 16 that is zigzag-folded multiple times. A detail of the filter bellows 17 is shown in FIG. 3. Folds 18 of the filter medium 16 extend between the inflow side 12 and the outflow side 14. A fold peak 20 of a fold 18 is positioned at the inflow side 12 and at the outflow side 14, respectively. Lateral surfaces 22 of the filter element 10 that cannot be flowed through are surrounded by a polyester nonwoven which is provided on the side that is facin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com