Anode construction and method for deploying anode construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

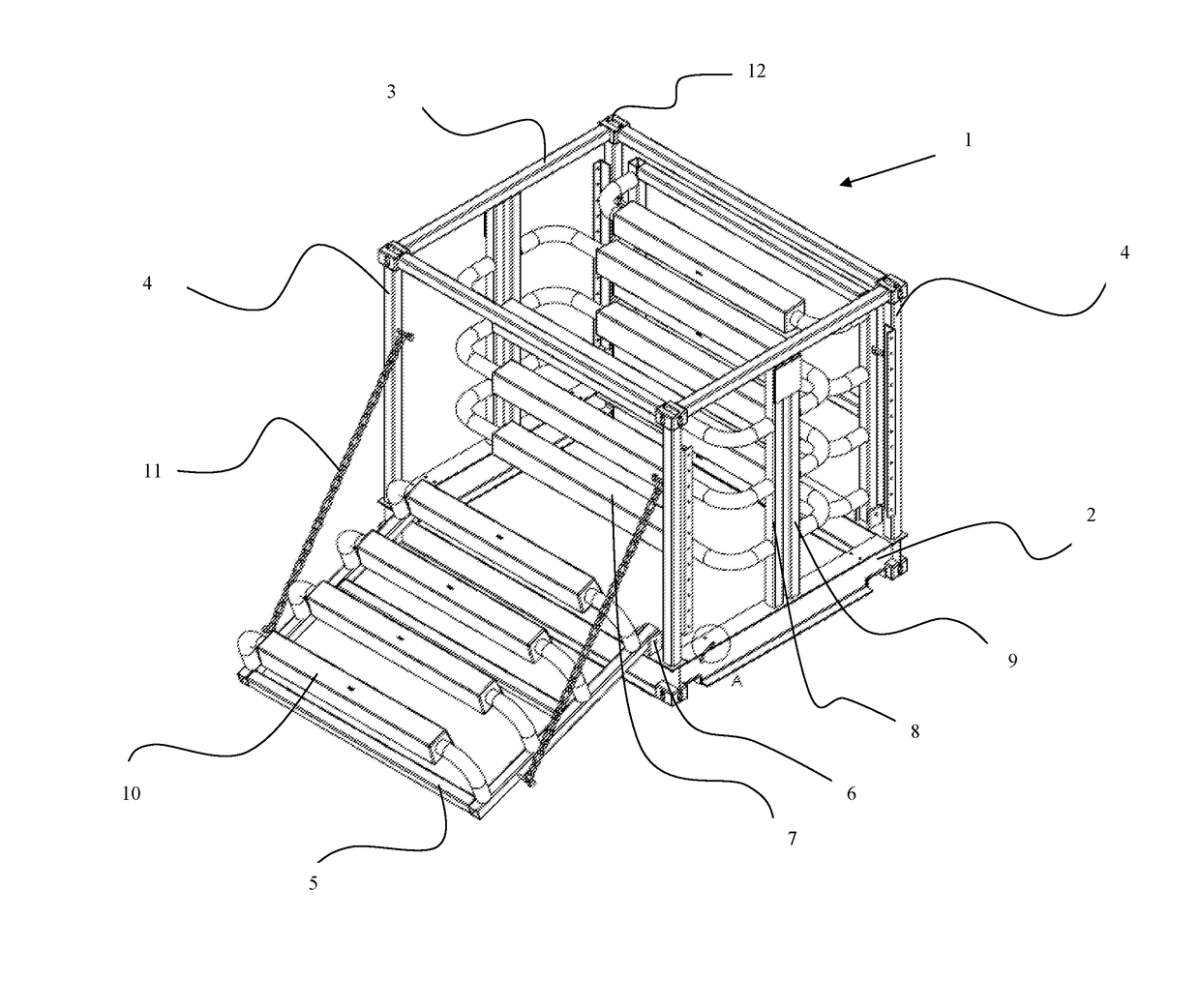

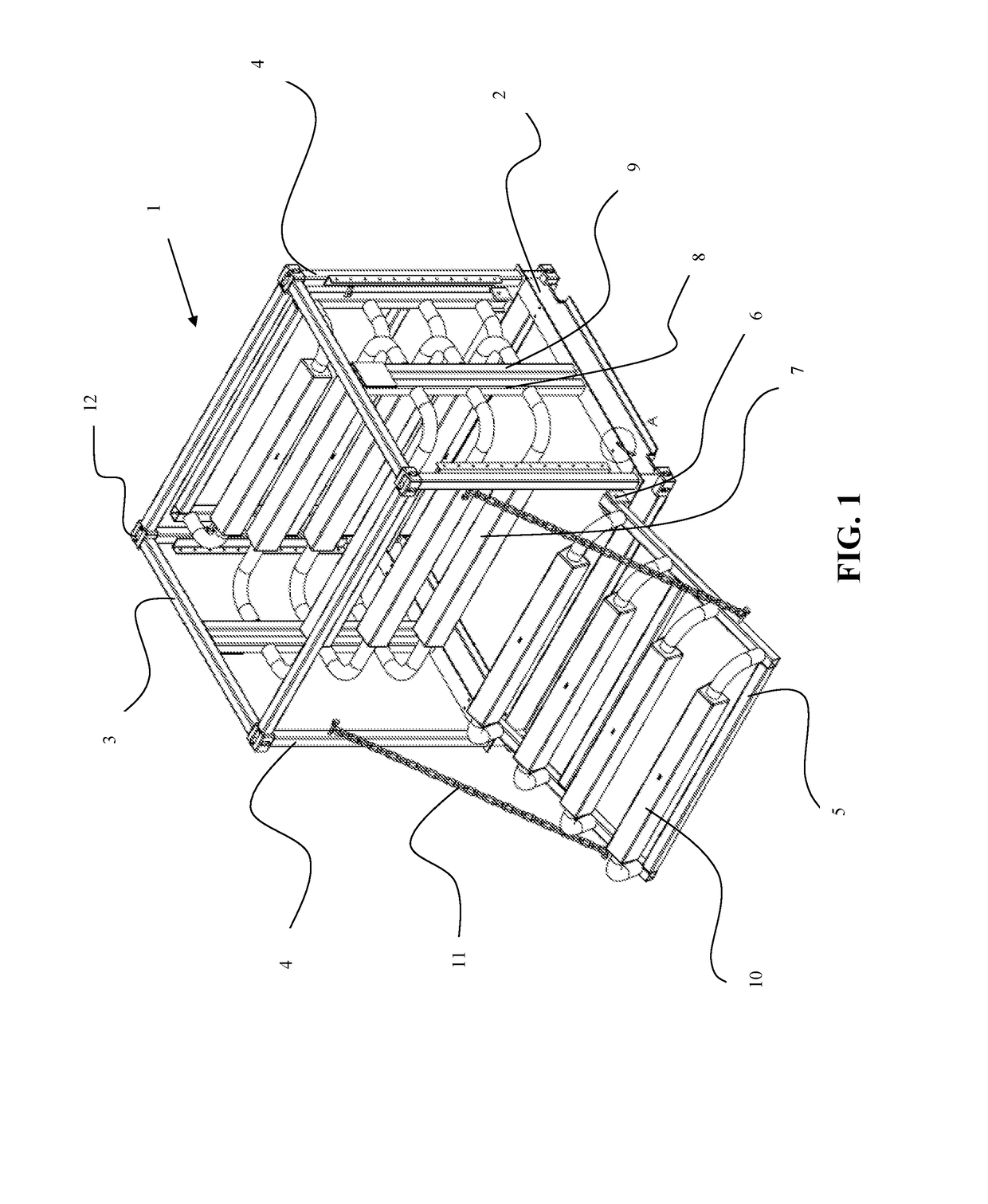

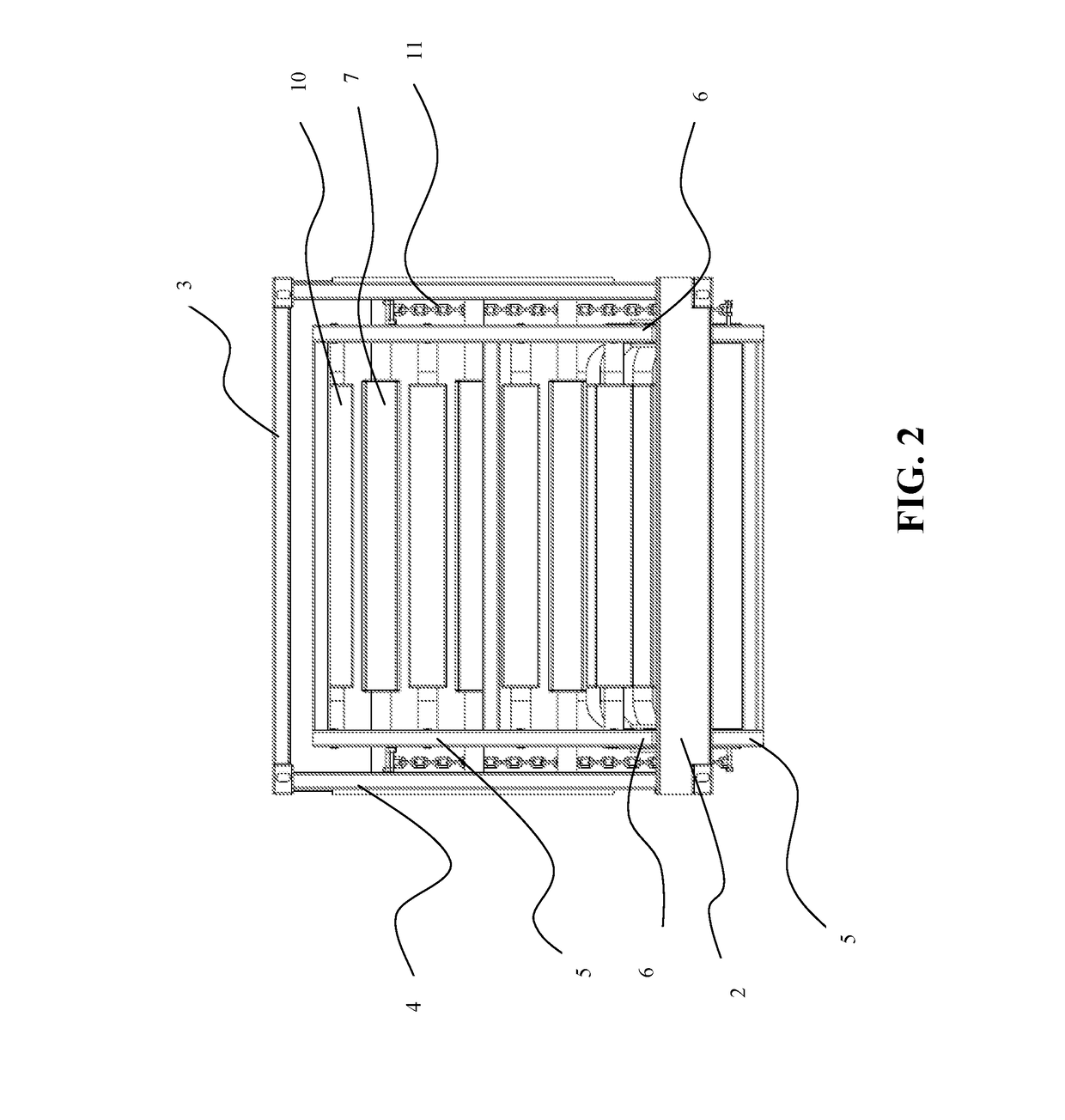

[0038]From FIG. 1 the anode construction 1 according to the invention appears in a perspective view. The construction comprises a frame with a rectangular bottom part 2 and a rectangular top part 3 and at four perpendicular corner posts 4 extending between the bottom part 2 and the top part 3. Between the corner posts 4 the frame defines two opposed side areas and two opposed end areas. At the end areas and between the top part and the bottom part, stationary anode carrier elements 8,9 are provided. The stationary anode carrier elements 8,9 carry six anode elements 7, three towards each side area. At each side area and connected to the bottom part 2 a pivotable side part 5 is provided, connected to the bottom part 2 through hinges 6 at each side of the pivotable side part 5. Each pivotable side part 5 carries four anode elements 10. In order to control the pivoting position chains 11 are provided between the pivotable side part 5 and the corner posts 4. This mainly serves the purpos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com