Nanotube application deposition system for forming low defect nanotube fabrics

a nanotube and application deposition system technology, applied in the field of nanotube solution, nanotube film or fabric formation, can solve the problems that the solution made from raw nanotubes cannot be used in a semiconductor fabrication plant, negatively affecting the electrical properties of the nanotube film or fabric, etc., and achieves the effect of low impurity and defect levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

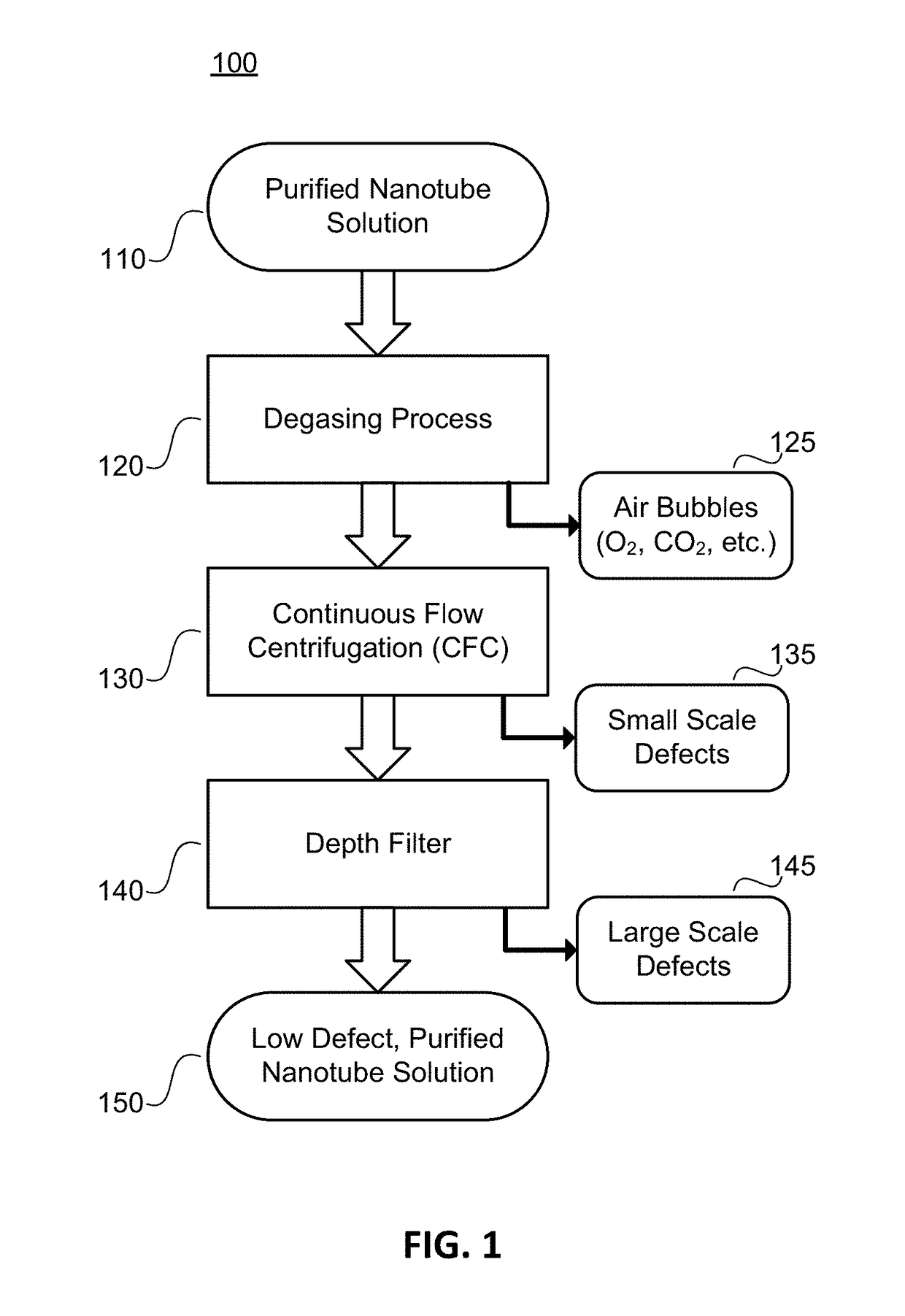

[0043]The present disclosure teaches methods for forming low defect nanotube application solutions that can be, in turn, used to provide nanotube fabrics with very low levels of both impurities and defects. As will be described in detail below, one or more defect reduction processes can be used to remove air bubbles, small scale defects, and large scale defects from a nanotube application solution and prevent defects from being transferred in a nanotube fabric formed from such a solution. According to the methods of the present disclosure, defect reduction processes include: a degassing process, a continuous flow centrifugation (CFC) process, a bulk centrifugation process, and processing through a depth filter. In one aspect of the present disclosure a degassing process is used to remove dissolved gases (such as O2 or CO2) from a suspension of nanotubes. In certain applications, the presence of air bubbles within a suspension of nanotubes can facilitate nanotube elements “clumping” ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com