Continuous flow centrifugal device

A technology of centrifugal device and body, applied in centrifuges and other directions, can solve problems such as generation of debris and contamination of raw liquid, and achieve the effects of improving safety, reducing waste, and reducing the probability of debris contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

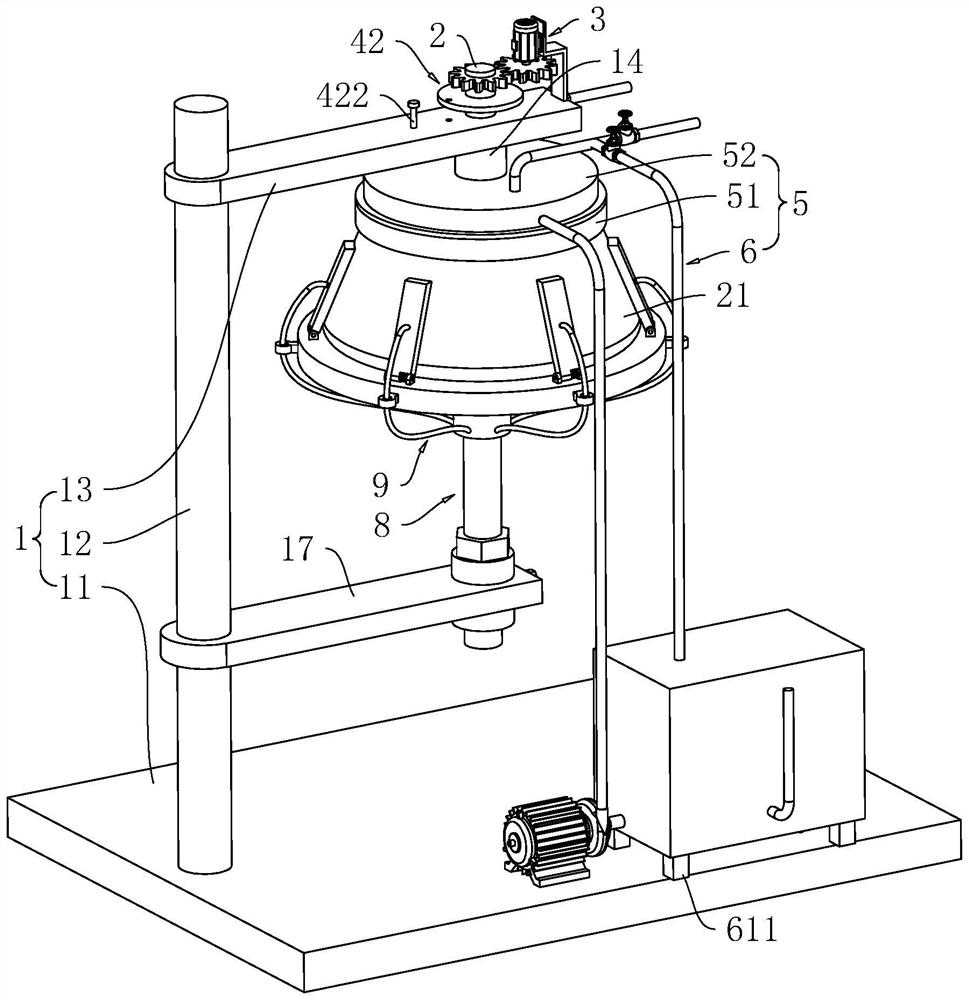

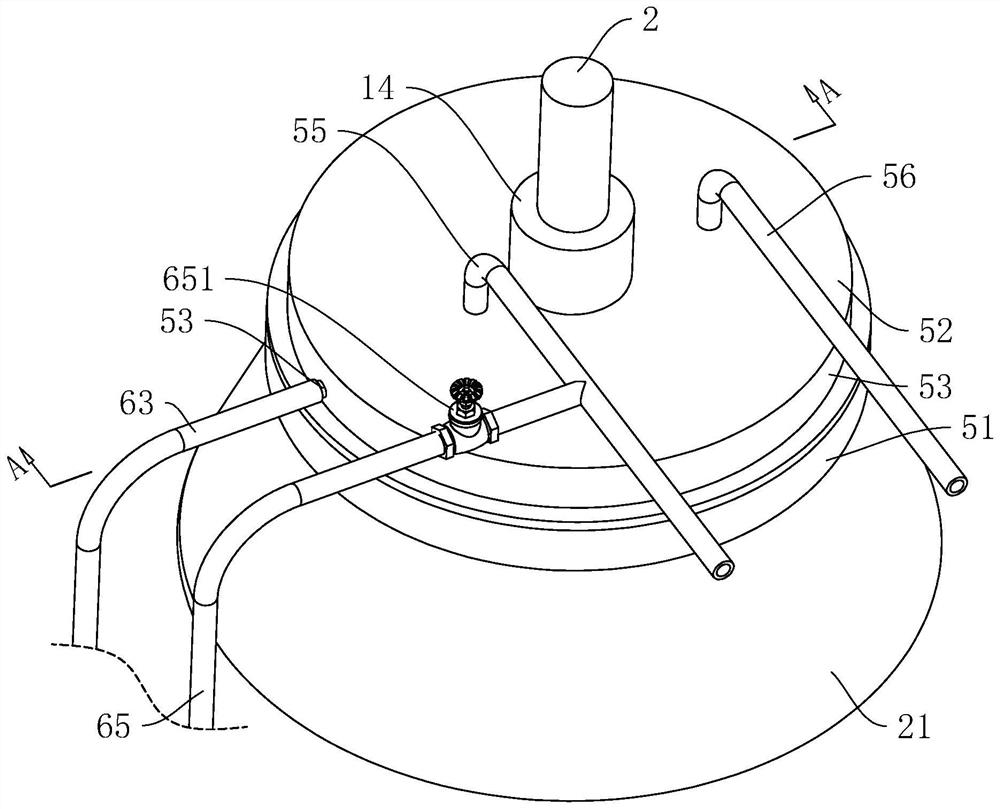

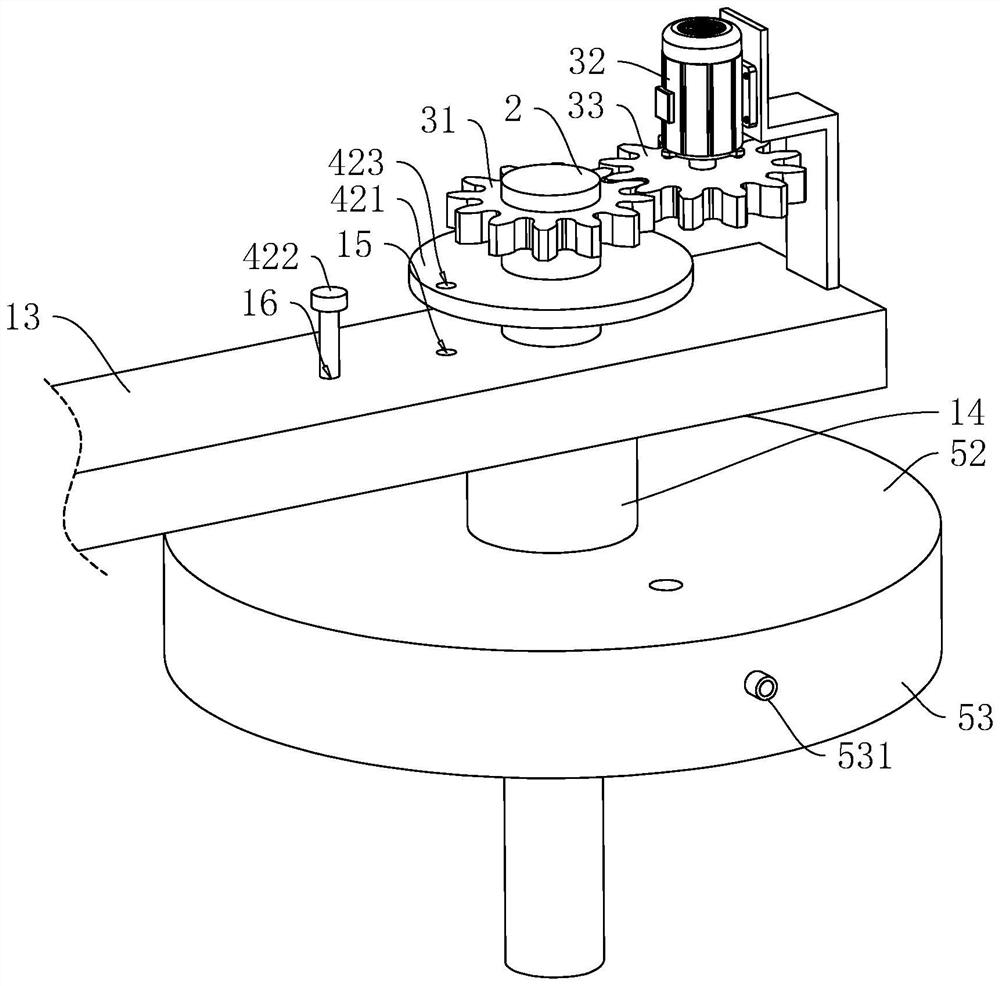

[0069] Below in conjunction with accompanying drawing 1-8, the present application is described in further detail.

[0070] The embodiment of the present application discloses a continuous flow centrifugal device.

[0071] refer to figure 1 , the continuous flow centrifugal device includes a body 1, a rotating shaft 2 mounted on the body 1, a rotating bowl 21 is detachably arranged on the rotating shaft 2 through a connecting assembly 4 for separating the stock solution, and the body 1 is provided with a driving rotating bowl 21 to rotate The driving device 3, the body 1 is provided with a sealing device 5 for sealing the rotating bowl 21 and a supporting device 8 for supporting the rotating bowl 21.

[0072] refer to figure 1 and figure 2 , the body 1 includes a machine platform 11, a support rod 12 and a mounting plate 13, the support rod 12 is fixedly mounted on the upper surface of the machine platform 11 and is in a vertical state, one end of the mounting plate 13 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com