A method for large-scale production of high-purity porcine pseudorabies virus

A porcine pseudorabies virus and high-purity technology, which is applied in the field of large-scale production of high-purity porcine pseudorabies virus, can solve the problems of increased residual concentration of harmful substances, increased effective antigen content of vaccines, safety of vaccine products, etc. Effects of vaccine side reactions, reduction of antigen loss, and good promotion prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. Hollow fiber column clarification process

[0044] 1 system pretreatment

[0045] 1.1 Install the 0.2μm, 0.45μm, and 0.65μm hollow fiber columns into the hollow fiber column control equipment respectively, connect the corresponding pipelines, and soak the hollow fiber columns with sterile injection water for 10 minutes after assembly.

[0046] 1.2 System Integrity Detection

[0047] The pressure hold method checks the integrity of the system.

[0048] 1.3 System processing

[0049] Cleaning and sterilization: Use sterile 0.5mol / L NaOH solution to sterilize the system for 30 minutes, then clean the system with sterile water for injection to remove residual alkali solution until the pH is 7.0;

[0050] 1.4 Detection of water flux

[0051] Use sterile water for injection to pass through at the specified pump speed, and calculate the water flux of the hollow fiber column at the corresponding temperature.

[0052] 1.5 hollow fiber column balance

[0053] Equilibrate...

Embodiment 2

[0061] 1. Hollow fiber column ultrafiltration concentration process

[0062] 1 system pretreatment

[0063] 1.1 Install the 300KD, 500KD, and 750KD hollow fiber columns into the hollow fiber column control equipment respectively, and connect the phase

[0064] Appropriate pipelines, after assembly, soak the hollow fiber column with sterile water for injection circulation for 10 minutes.

[0065] 1.2 System Integrity Detection

[0066] The pressure hold method checks the integrity of the system.

[0067] 1.3 System processing

[0068] Cleaning and sterilization: Use sterile 0.5mol / L NaOH solution to sterilize the system for 30 minutes. Then clean the system with sterile water for injection to wash away the residual alkali solution until the pH is 7.0.

[0069] 1.4 Detection of water flux

[0070] Use sterile water for injection to pass through at the specified pump speed, and calculate the water flux of the hollow fiber column at the corresponding temperature.

[0071] 1...

Embodiment 3

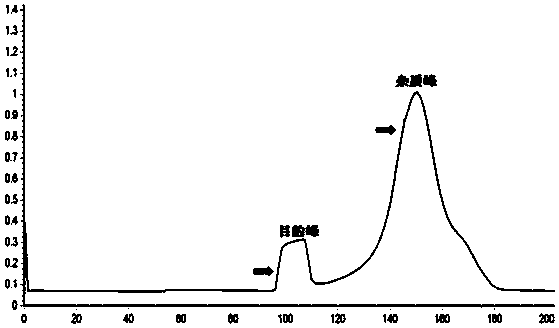

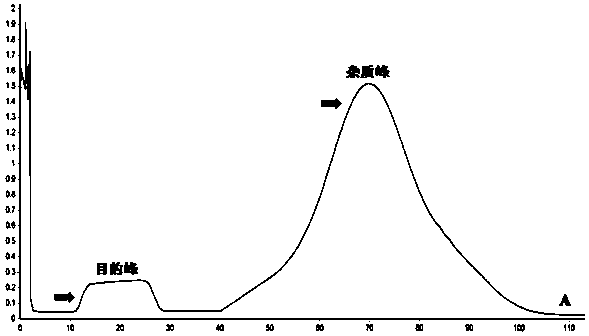

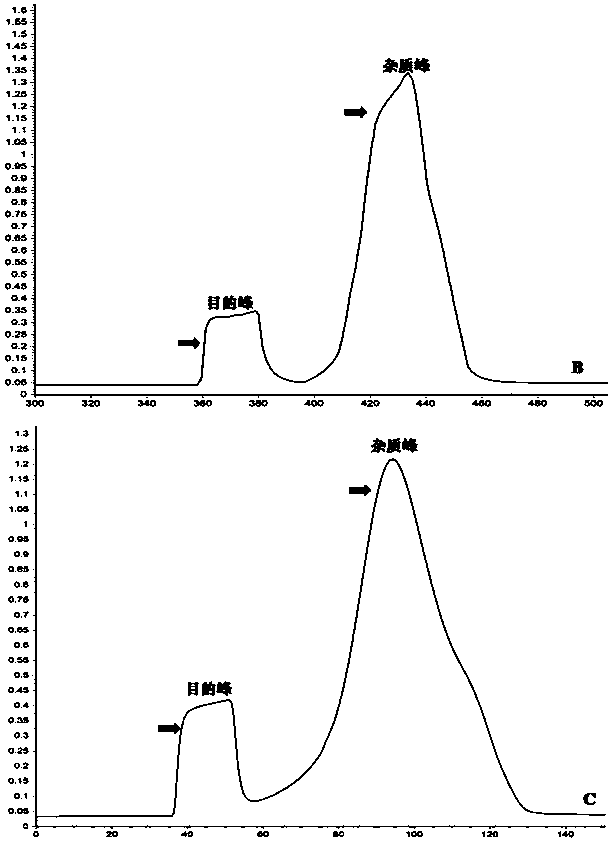

[0078] Embodiment 3 molecular sieve gel chromatography process

[0079] 1 system pretreatment

[0080] 1.1 Install the 4FF molecular sieve prepacked column in place and measure the column efficiency.

[0081] 1.2 Treat 2 column volumes (CV) of the molecular sieve gel chromatography column with sterile 0.5mol / L NaOH, then wash with sterile injection water to pH 7.0, and then equilibrate the ion exchange column with 0.01mol / L PBS solution to reach the conductivity The column rate is consistent before and after the column (the conductivity before and after the column is 15.69ms / cm), the pH is stable at 7.0, and the UV 280 The baseline is stable.

[0082] 2 Purification process

[0083] Load the concentrated virus sample, set the linear flow rate of the sample to 30cm / h, and control the pressure to less than 2.0bar. The loading volume is 5%, 10%, and 15% of the column volume. After loading the sample, start to elute the protein with 0.01mol / L PBS solution, and wait until the U...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com