Twist-base mount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

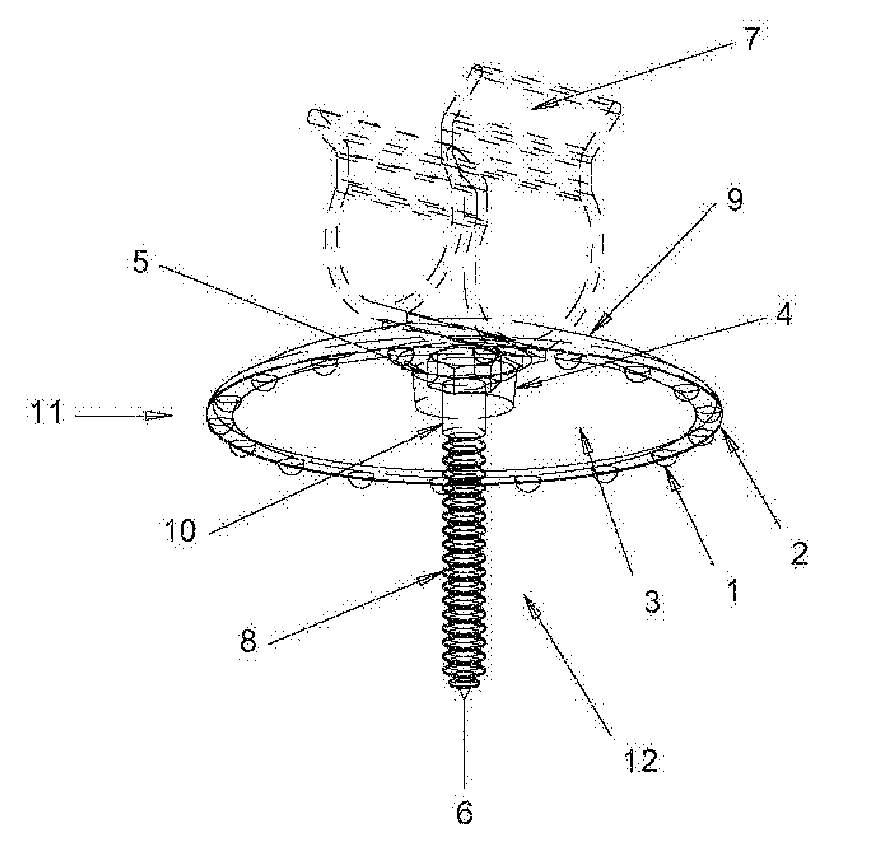

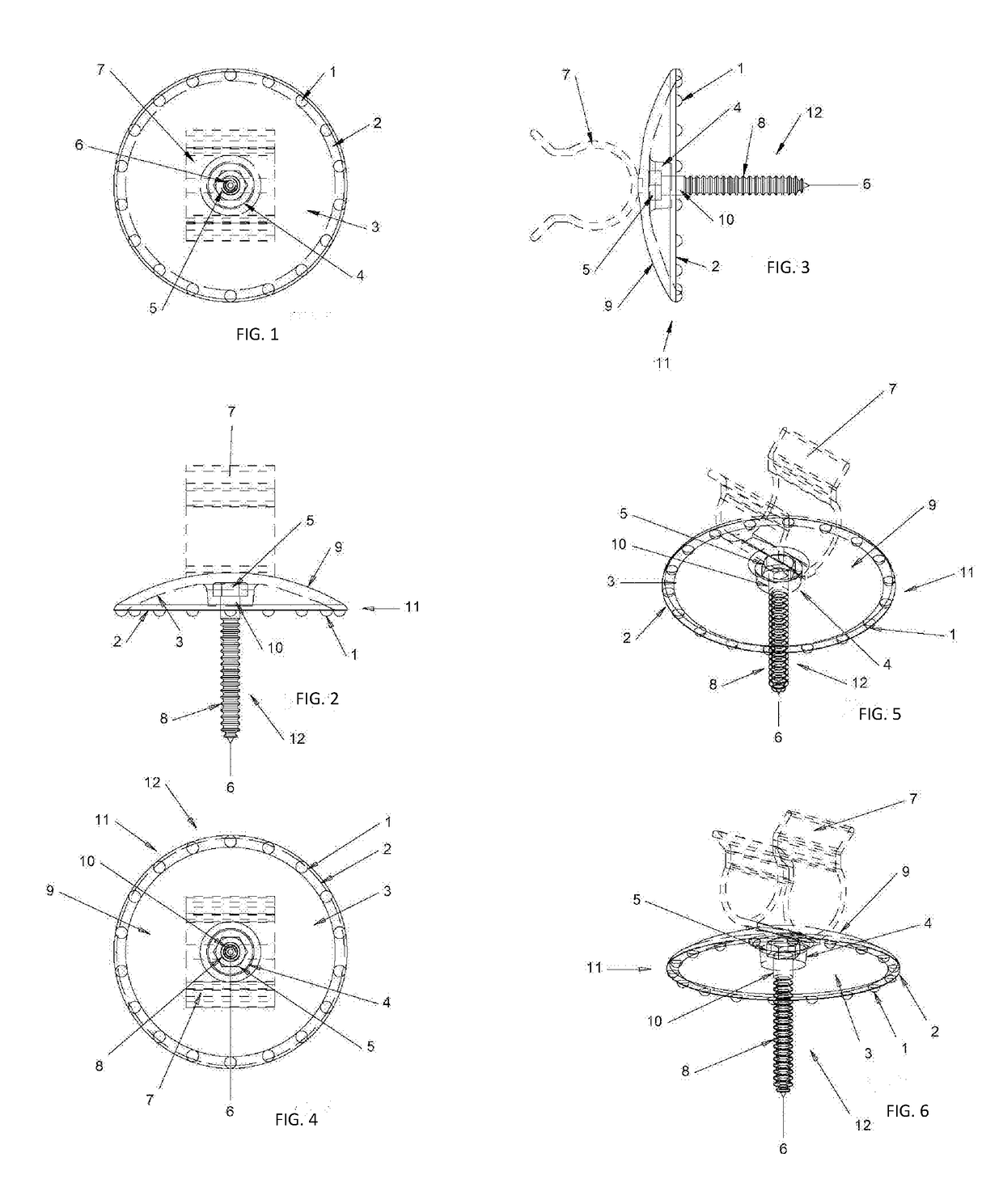

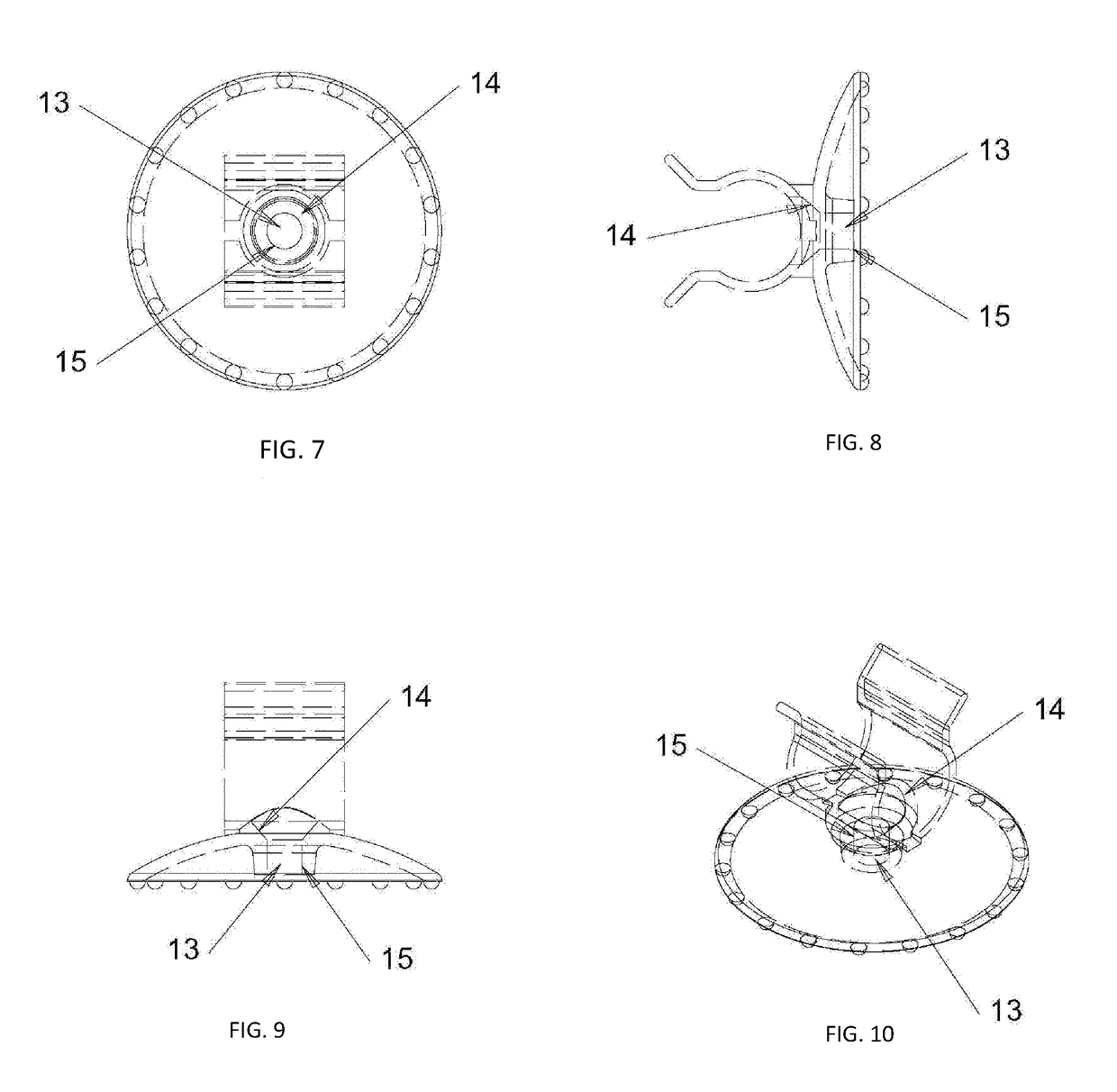

[0016]Referring to FIGS. 1-6, a stable, rotatably-adjustable, self-boring mount for fixtures (the “Twist-Base Mount” or “Mount”), comprises a hollow, deformable, dome-shaped base element 11 made of a thermoplastic material. The dome shape can be a section of a sphere or an ellipsoid cut by a plane in which the ratio of the width of the base to the height of the base can be between 4 inches and 8 inches. The diameter of the base can be from 1.5 inches to 2.5 inches. A self-boring, screw element 12 is attached to the underside of the base element. Base element 11 comprises a convex, fixture-supporting topside portion 9, a concave, substrate-facing, underside portion 3 opposite the topside portion, a generally cylindrical or frustoconical hub 4 extending perpendicularly away from the center of said underside portion 3, and a substrate-engaging portion defined by a circumferential edge 2. A plurality of protuberances 1 (each, a “detent” or “nub”) are defined on the circumferential edge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com