Pallet for Hand Trucks and Dollies

a technology for dollies and pallets, which is applied in the field of hand trucks, dollies and barrows, and can solve the problems of not being able to provide the ease of shipping of a pallet with the small size, and using the normal large size of pallets,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

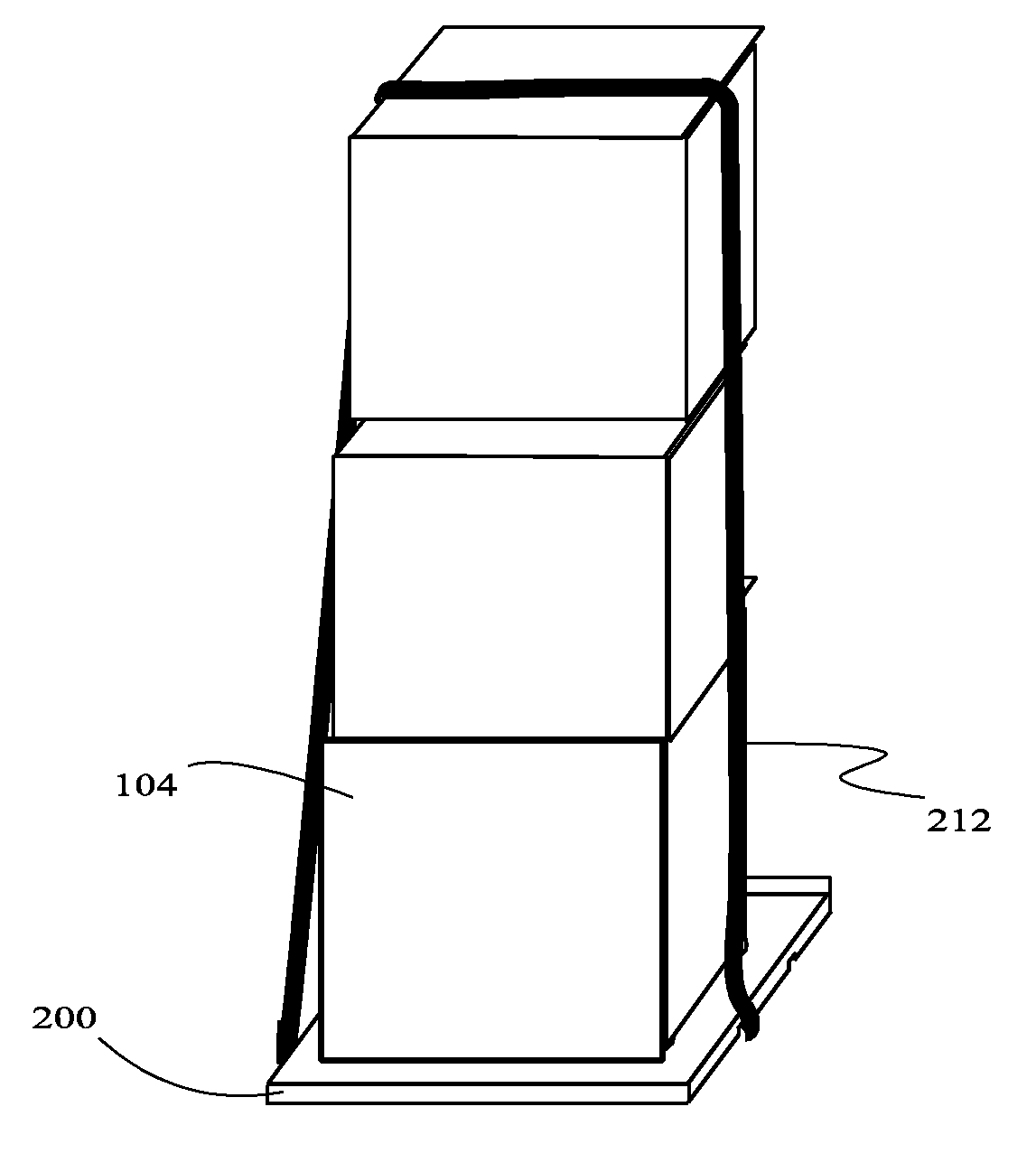

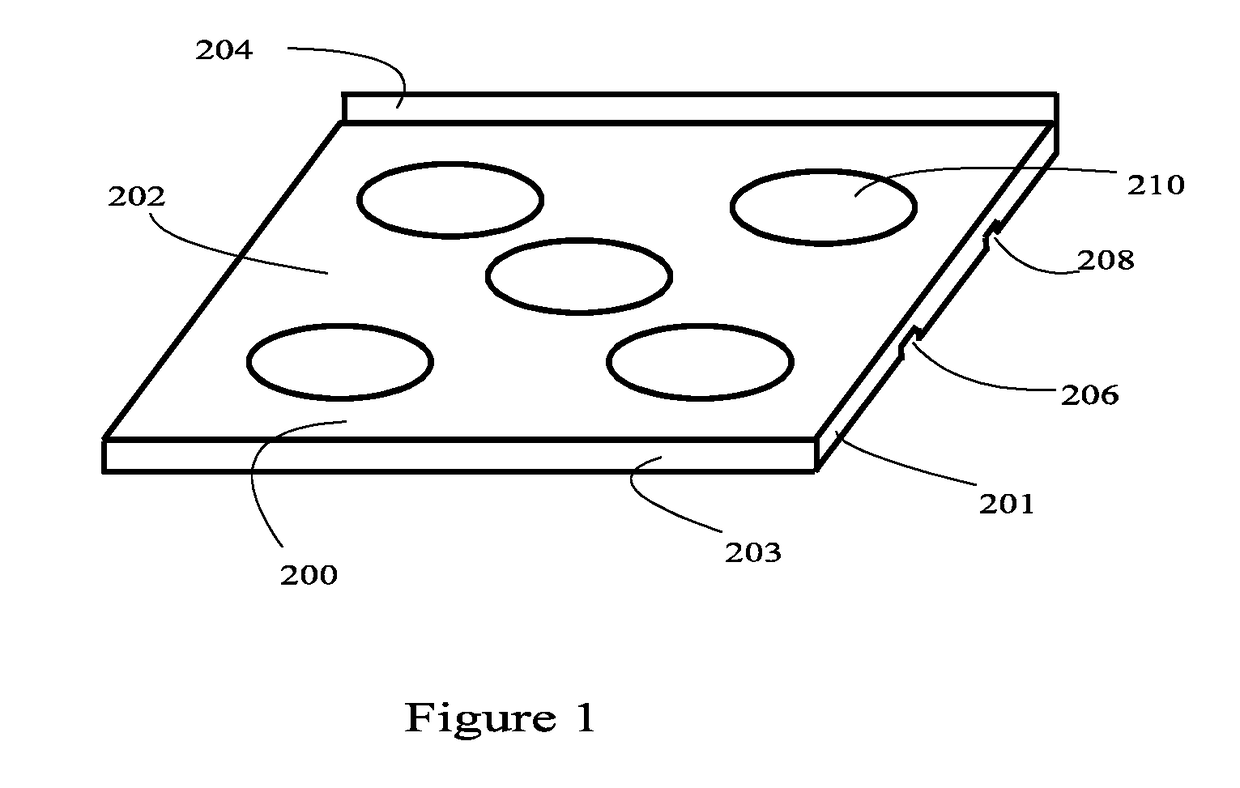

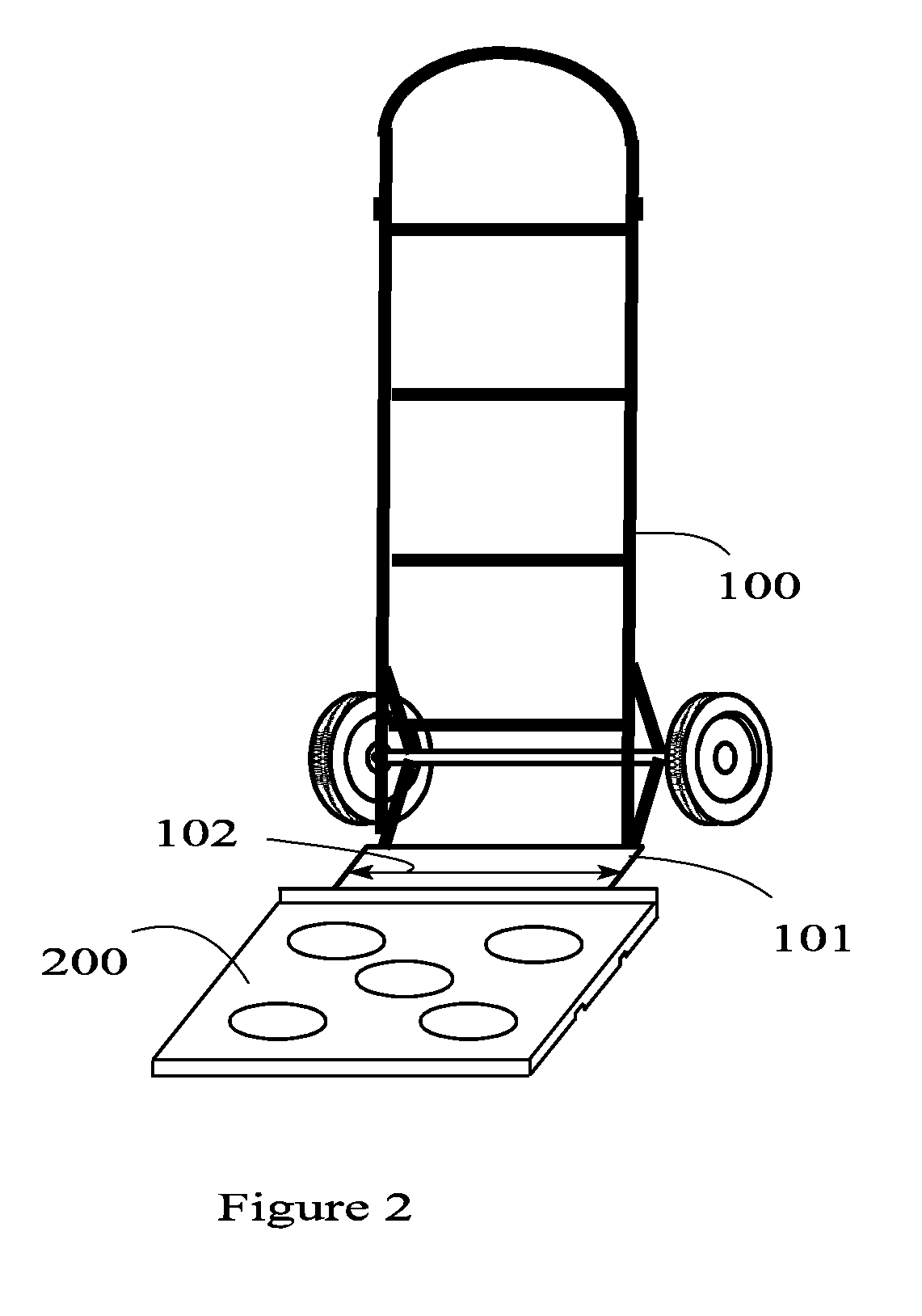

[0094]FIG. 1 is an orthogonal elevated frontal view of the device of the invention, showing details of the top view of the hand truck pallet thereof. Hand truck pallet 200 has a body of generally rectangular shape by preference, although other shapes are possible in alternative embodiments. Side wall 201 and the matching side wall (not seen) cooperate with the front wall 203 to support the device. Since it is a box structure and not a solid structure this leaves an undercarriage area or interior space.

[0095]Top surface 202 is the load bearing surface of the invention, on which cargo will be placed. Note that speed holes 210 serve to save weight and cost.

[0096]Back wall / load rail 204, along with the side walls 201 and front wall 203, act to provide rigidity and strength. In the case of load rail 204, it further serves to check the slide of cargo on the pallet when the pallet is tilted, however, normally the hand truck's vertical body will act in this fashion in any case.

[0097]The sid...

second embodiment

[0107]FIG. 6 is a rear view of the invention having adjustable Z-bars, showing the undercarriage space within / underneath the hand truck pallet of the invention.

[0108]Locking mechanism width 214 is shown by arrow. This width is important to the use of the invention, since the distance separating the two facing parts of the locking mechanism (rails made of z-bars in this embodiment) should be less than the width of the nose plate of the hand truck with which the hand truck pallet will be used, while the same distance, plus the width of the small gaps 222, should be greater than the width of the hand truck nose plate. By this means the hand truck nose plate may fit into the rails 218 by means of sliding and yet be unable to fall out the bottom.

[0109]Interior space / under carriage 216 may also be seen from the rear view, since the load rail 204 is bent upward, unlike the front 203 and sides 201 which bend downward and hide the space while supporting the device clear of the floor.

[0110]Z-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com