Combustor front assembly for a gas turbine

a technology for gas turbines and components, applied in continuous combustion chambers, combustion processes, lighting and heating apparatus, etc., can solve the problems of high vibration, frequent failure of the foregoing described hook fixing system solution of the prior art, etc., and achieve the effect of increasing the lifetime and the reliability of the fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056]In cooperation with attached drawings, the technical content and the detailed description of the present invention are described thereinafter according to preferable embodiments, being not used to limit its executing scope. Any equivalent variation and modification made according to appended claims is all covered by the claims claimed by the present invention.

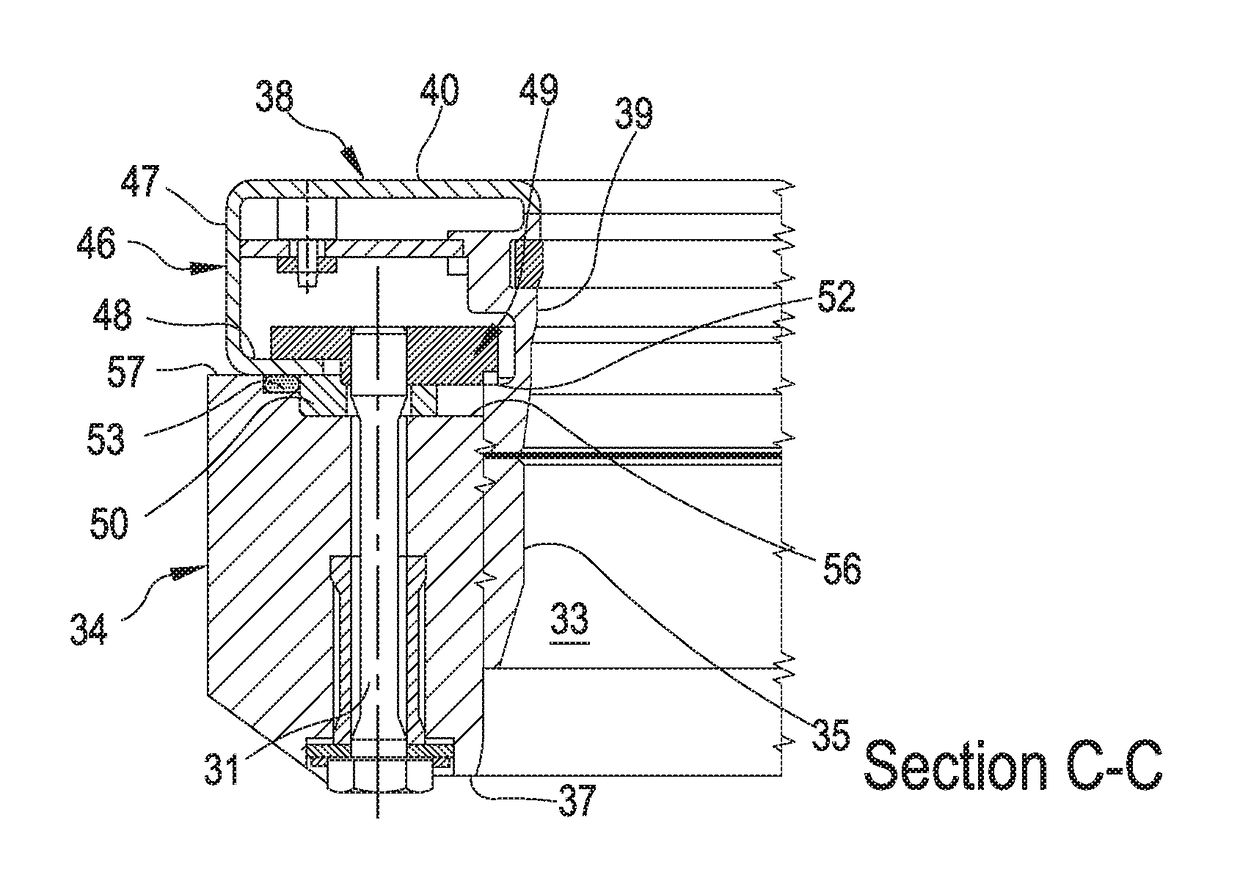

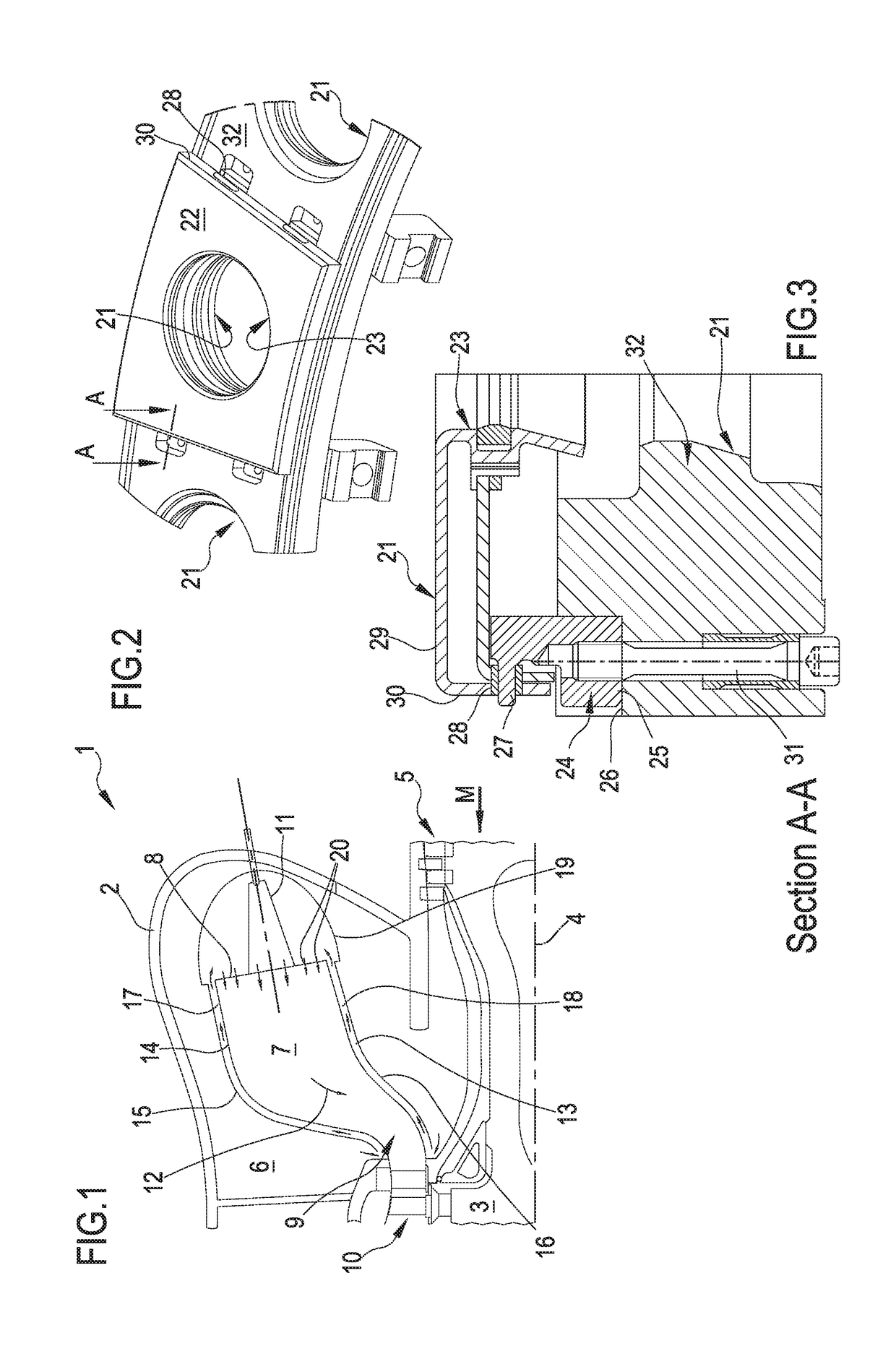

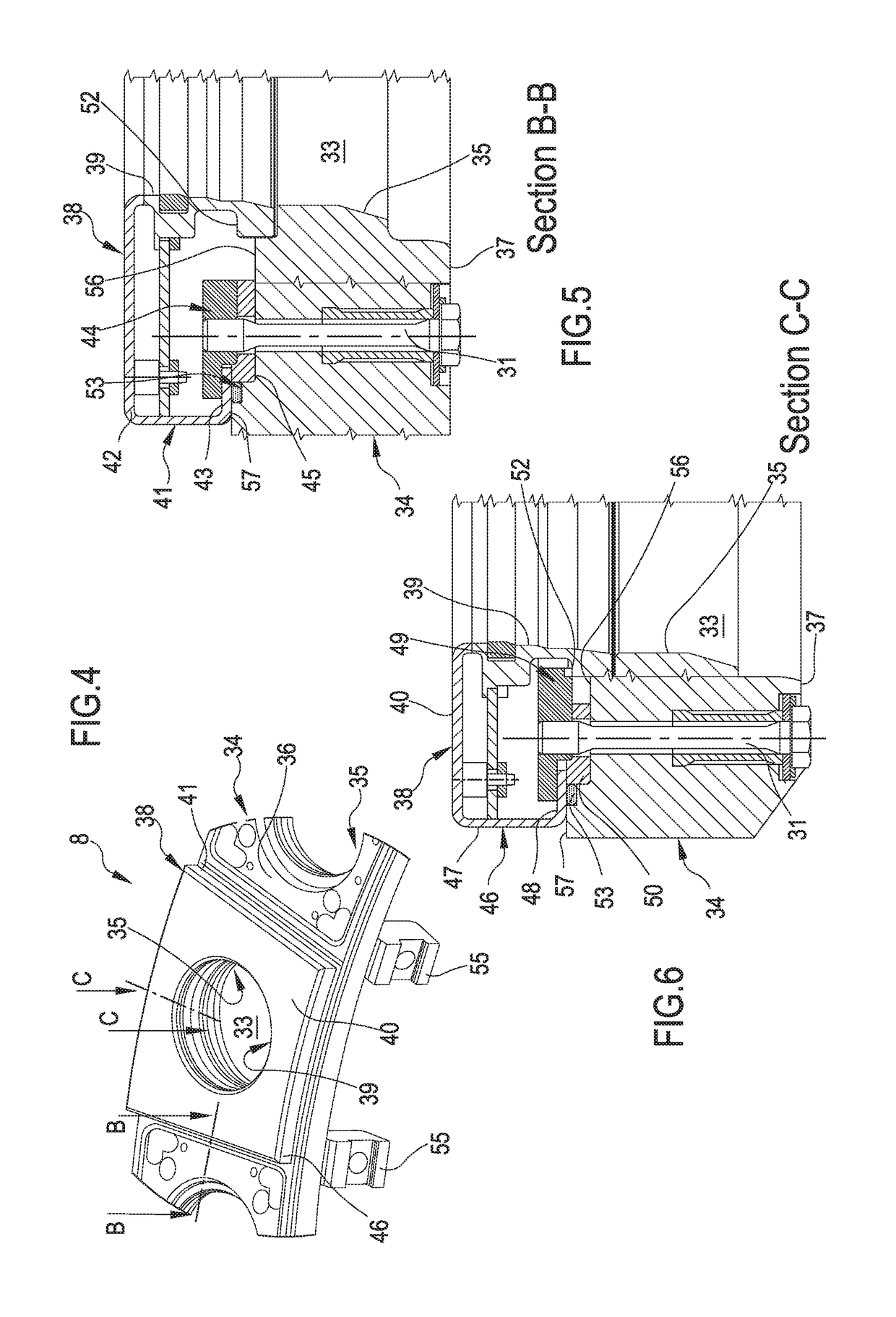

[0057]In particular, reference will be made to the FIGS. 4-11 that disclose in detail an embodiment of the present invention. Reference to FIG. 1, that is a schematic view of a gas turbine, will be made only in order to explain how the invention cooperates with the relative gas turbine.

[0058]Reference in now made to the FIG. 4 that is a schematic partial prospective view of a front combustor assembly, on the burner side, according to the invention.

[0059]In particular, the FIG. 4 discloses a portion of a ring-shaped combustor front plate 34 centered around the turbine axis 4 (see also FIG. 1) and a tile-shaped combustor fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com