Structure and method of foam-injection molding including el sheet

a technology of foam injection molding and el sheet, which is applied in the direction of vehicle interior lighting, transportation and packaging, and other domestic articles, can solve the problems of deteriorating the beauty of the handle unit b>10/b>, night view visibility is deteriorated, etc., and achieves the effect of enhancing the emotional quality of users and enhancing the beauty of vehicle interior materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]Exemplary embodiments of the present disclosure are described with reference to the accompanying drawings in detail. The same reference numbers are used throughout the drawings to refer to the same or like parts. Detailed descriptions of well-known functions and structures incorporated herein may be omitted to avoid obscuring the subject matter of the present disclosure.

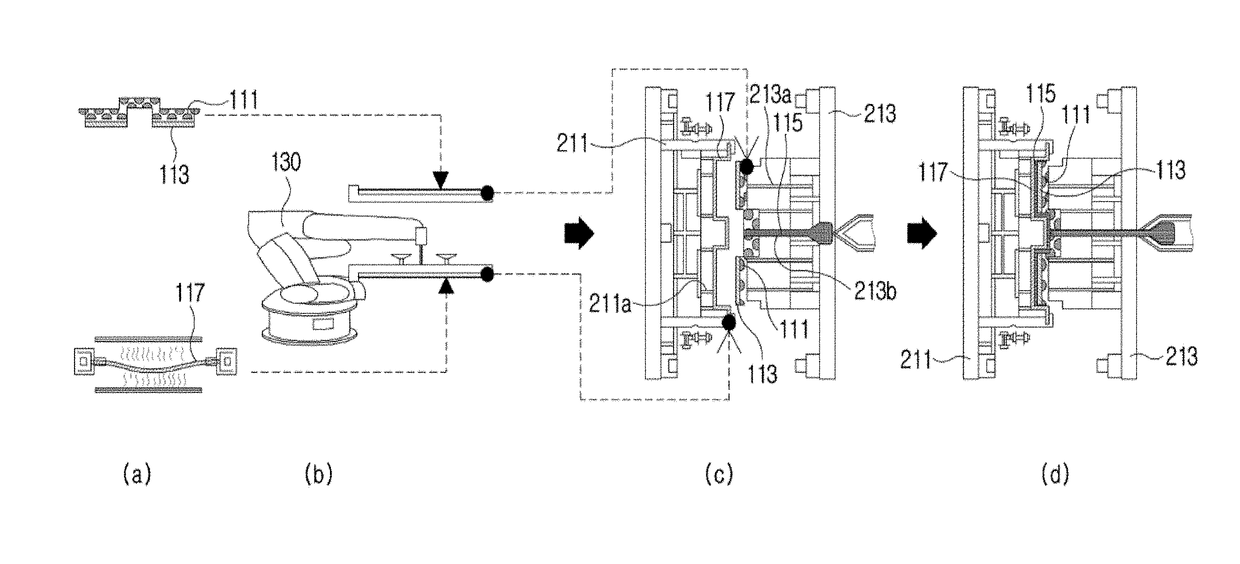

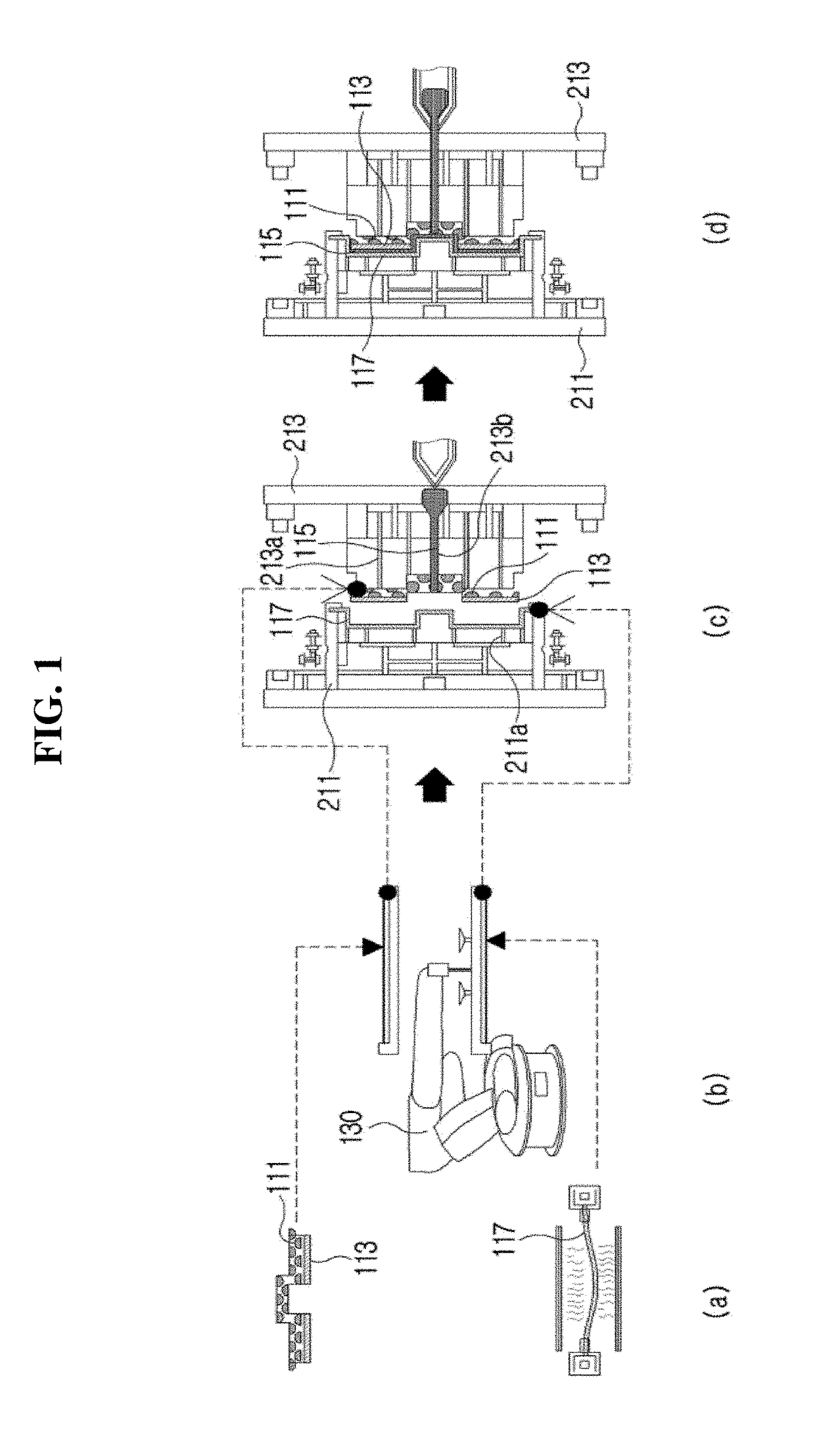

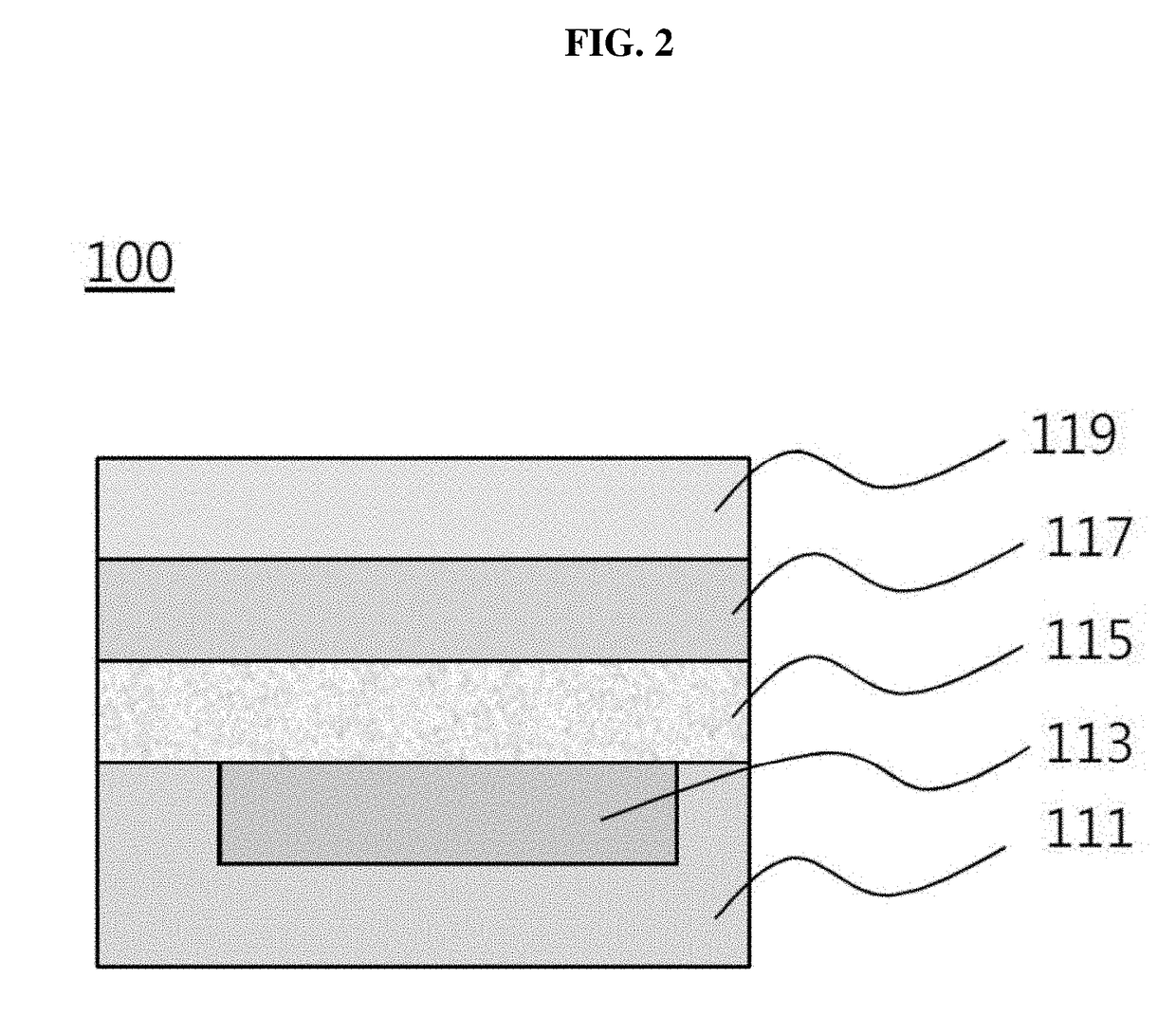

[0031]FIG. 1 illustrates a manufacturing process of a foam-injection molding structure including an EL sheet according to an exemplary embodiment of the present disclosure.

[0032]As shown in FIG. 1, a foam-injection molding structure including an EL sheet according to an embodiment of the present invention may include a preparation step A, a preforming step C, and an injection foaming step D.

[0033]The preparation step A may include a process of preheating a skin layer for heating in advance before mounting on a mold, and a process of adhering a base material and an electro luminescence (EL) sheet.

[0034]In this p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Structure | aaaaa | aaaaa |

| Fluorescence | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com