Automated storage and retrieval system for pallets and cases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

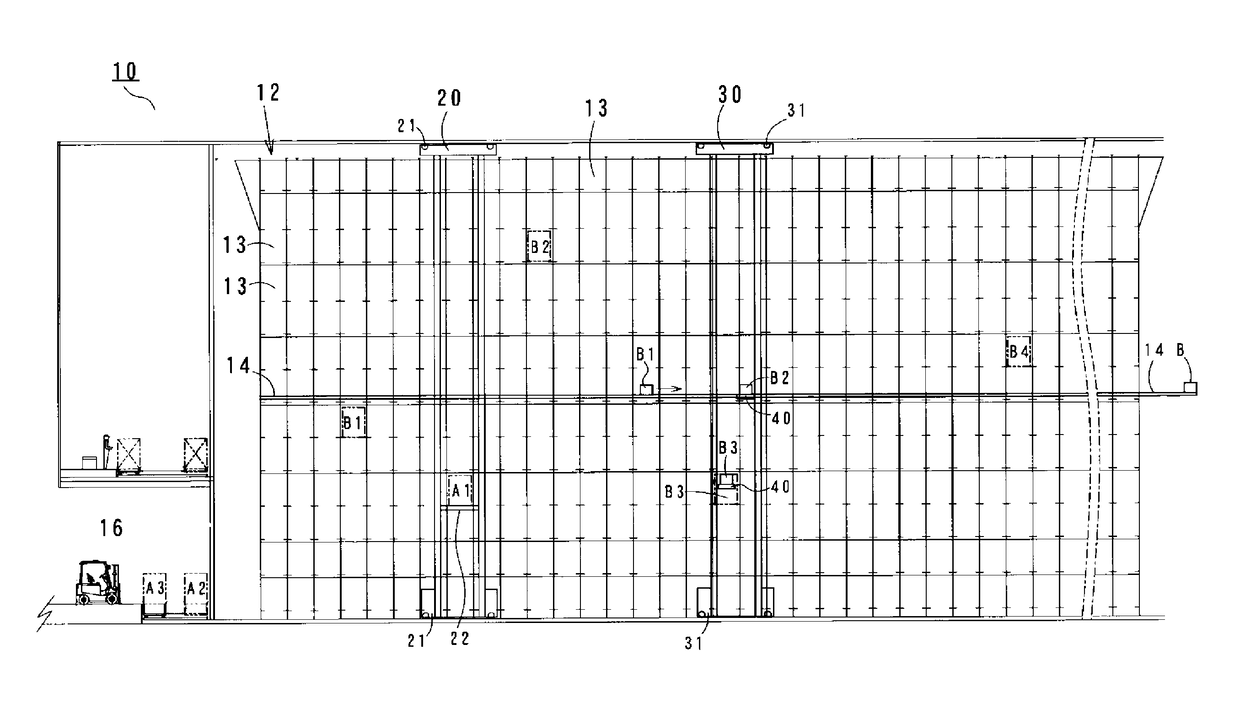

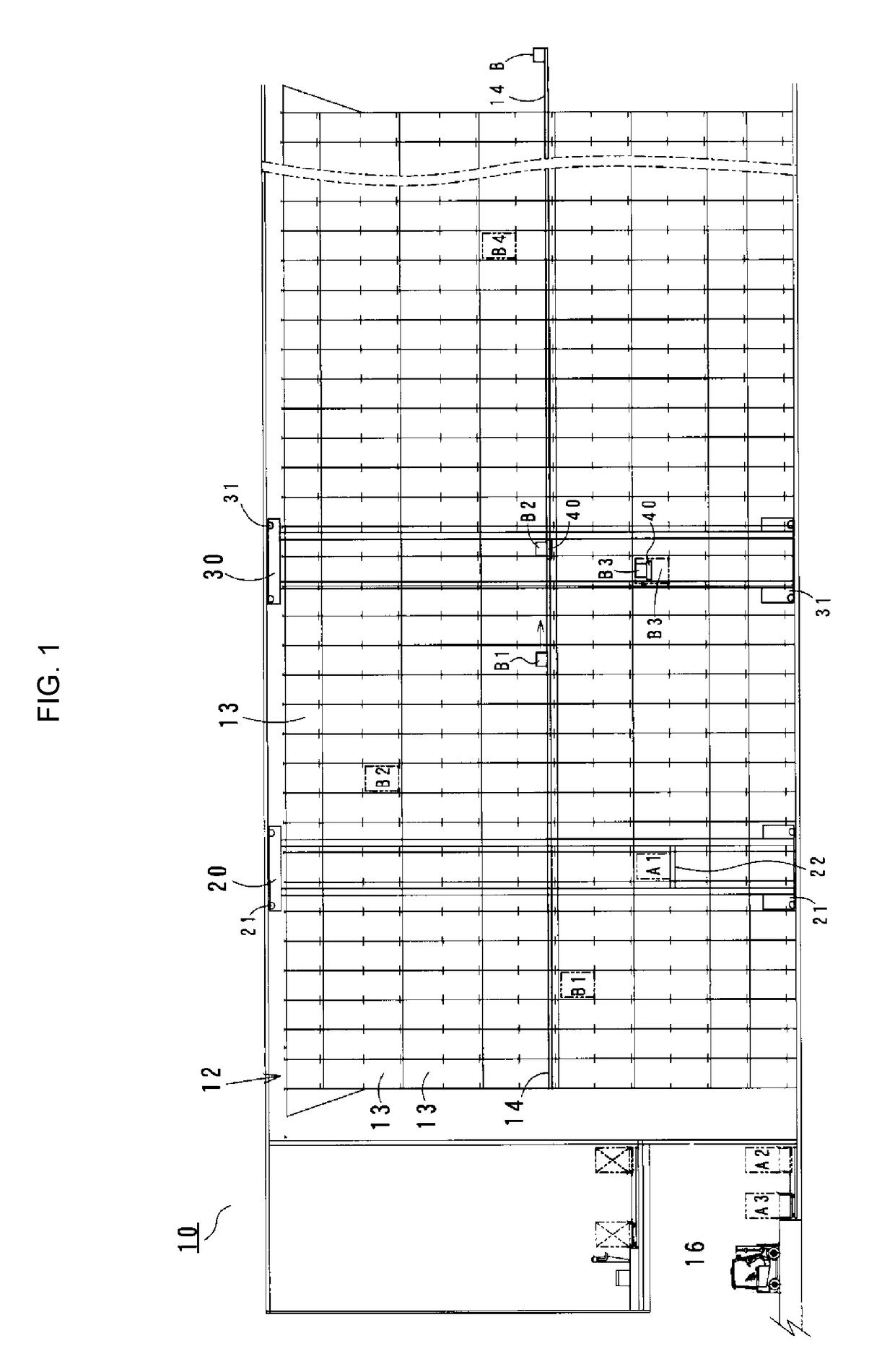

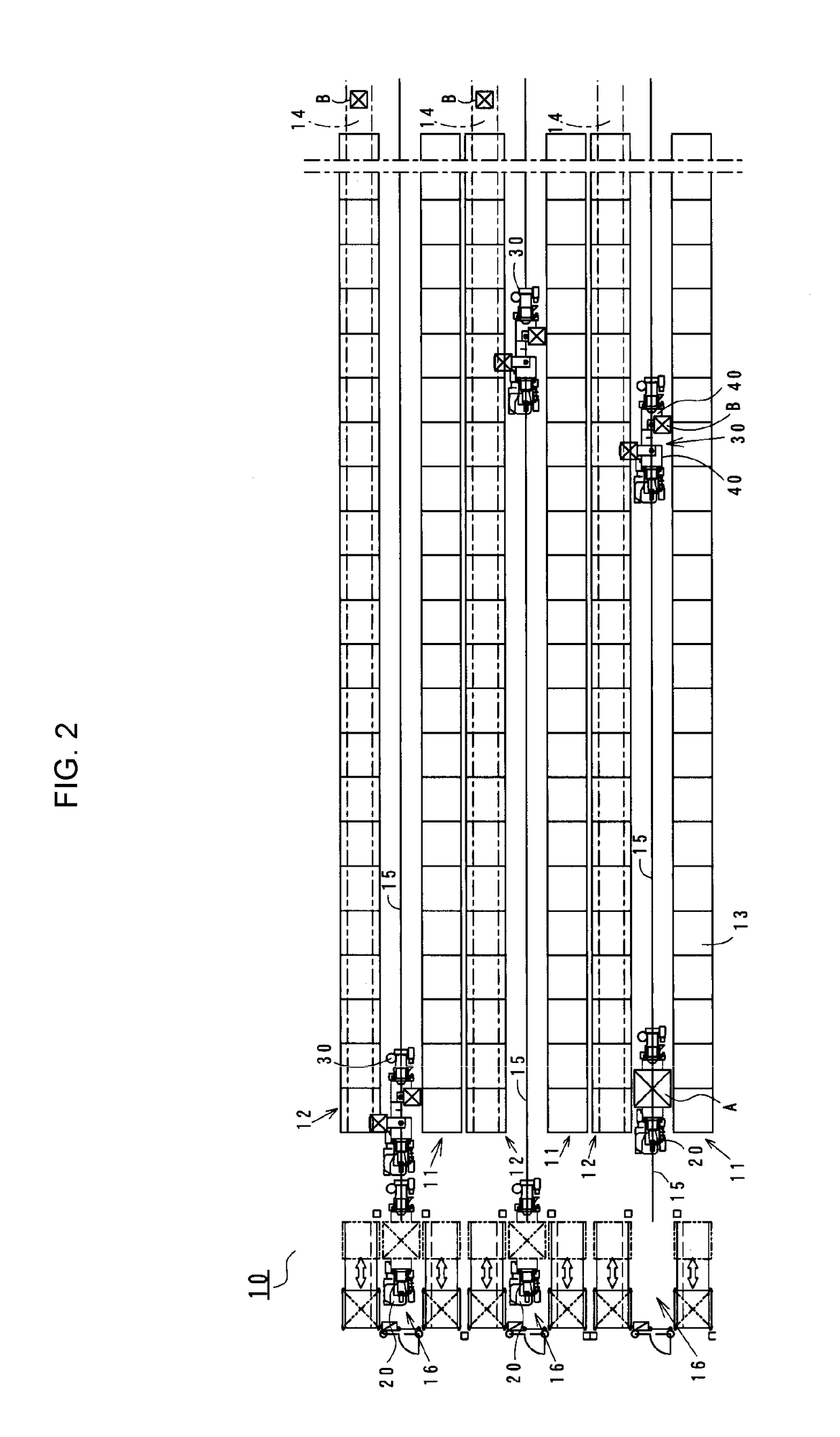

[0020]An embodiment of the present invention will now be described in detail with reference to the attached drawings. FIGS. 1 and 2 are a schematic side view and schematic plan view, respectively, illustrating an automated storage and retrieval system for pallets and cases; FIGS. 3A and 3B illustrate an embodiment of a case picking crane according to an embodiment; FIGS. 4A to 4G illustrate example picking motion of the case picking crane; and FIGS. 5A to 5F illustrate example operation of the automated storage and retrieval system for pallets and cases. In this embodiment, a pallet on which cases are stacked is called a pallet for simplicity's sake.

[0021]An automated storage and retrieval system 10 for storing and picking a pallet A and a case B includes: a storage rack 11 having a plurality of shelf boards 13 in rows and columns, wherein each of the shelf boards 13 is used for storage of the pallet A stacked with at least one case B; a storage rack with a built-in conveyor 12 that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com