Connection Device For Conveyors

a technology of connecting device and conveyor, which is applied in the direction of mechanical conveyor, conveyor parts, loading/unloading, etc., can solve the problems of insufficient, time-consuming, difficult and dangerous assembly, and prior art systems for joining together multiple mobile conveyors/mobile conveyor sections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

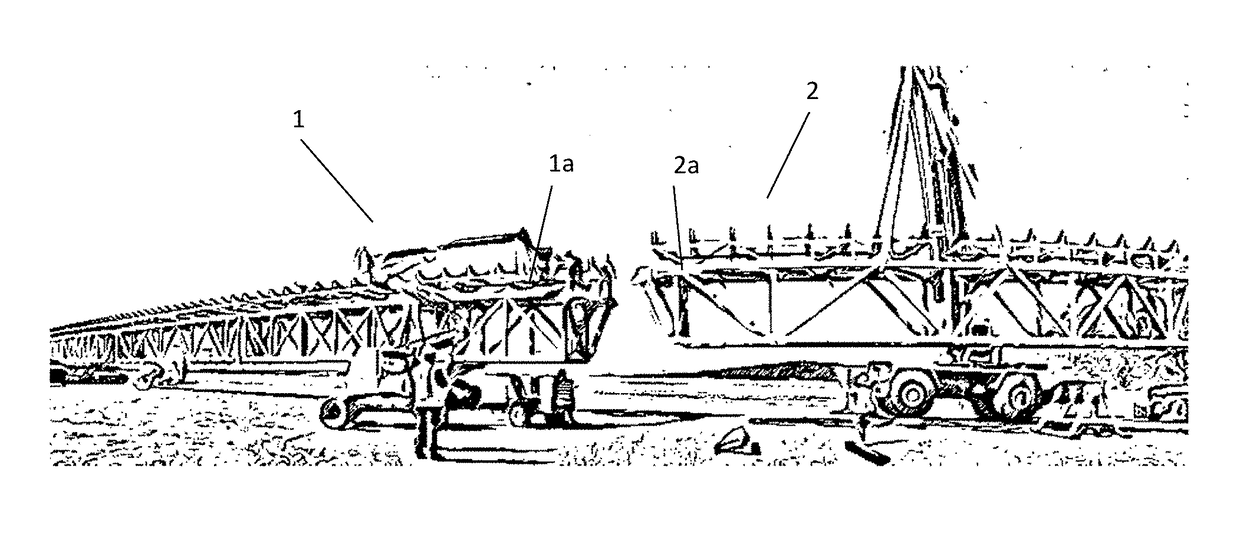

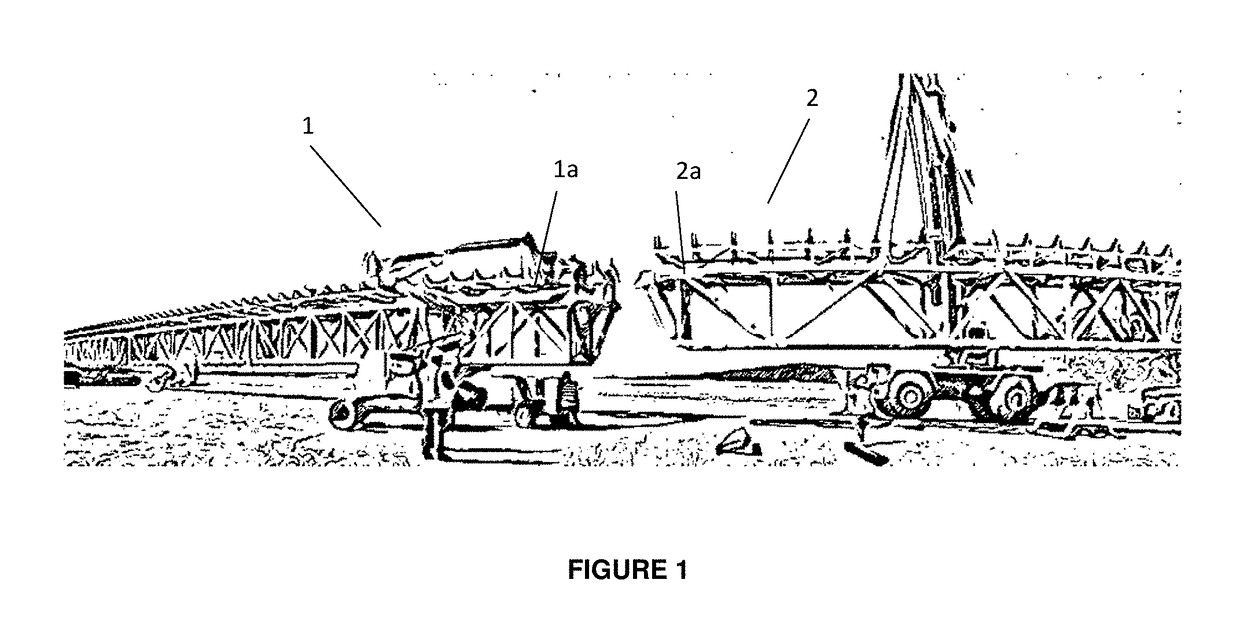

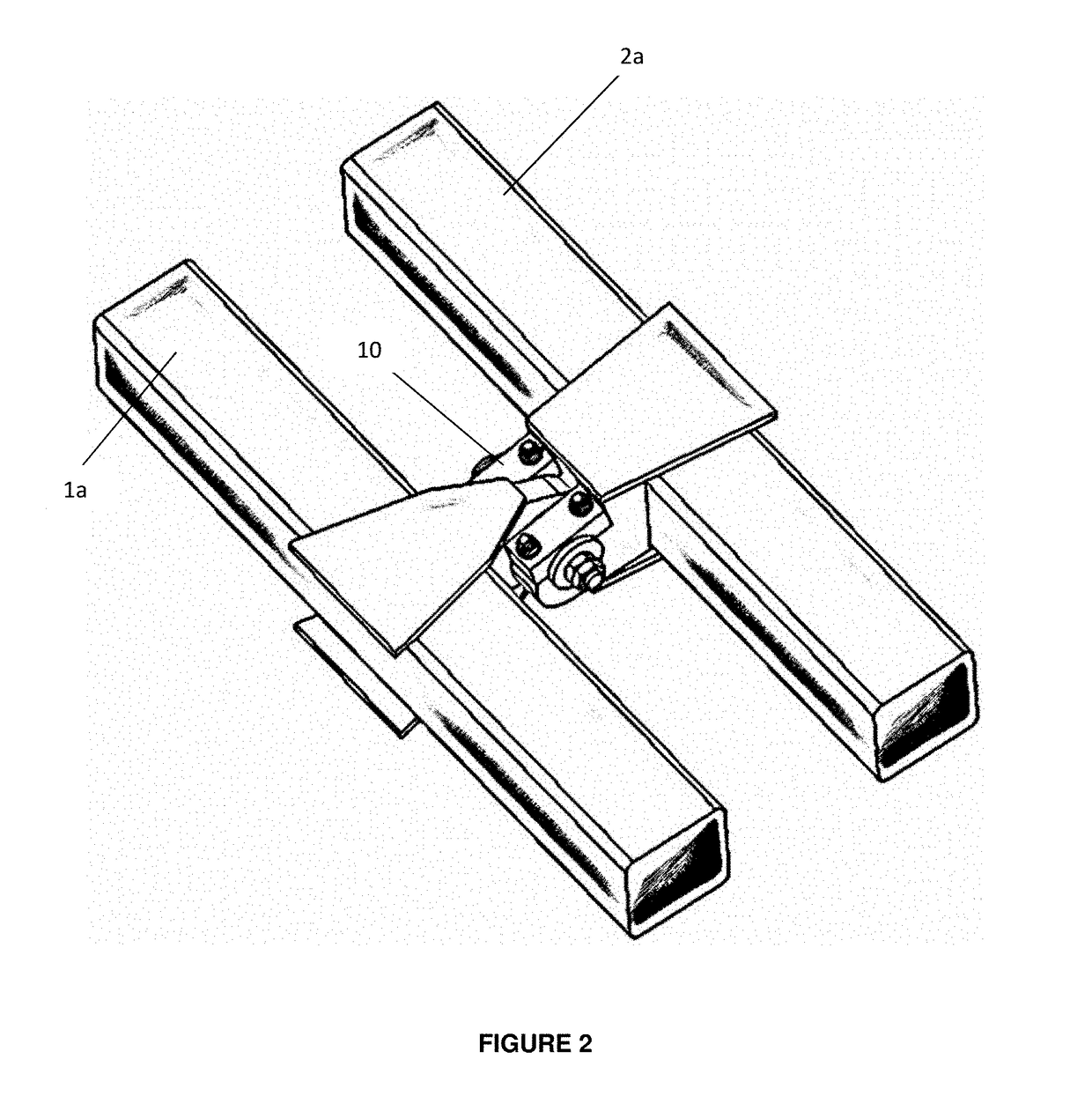

[0022]FIG. 1 depicts an exemplary embodiment of a mobile conveyor system. In an exemplary embodiment, the mobile conveyor system includes a first mobile conveyor (or first mobile conveyor section) 1 with a first mobile conveyor frame 1a and a second mobile conveyor (or second mobile conveyor section) 2 with a second mobile conveyor frame 2a. As shown in FIGS. 2-5, the mobile conveyor system also includes a connection device 10. The connection device 10 can be used for attaching and detaching the first mobile conveyor frame 1a to and from the second mobile conveyor frame 2a. In an exemplary embodiment, the connection device 10 is laterally disposed between the first mobile conveyor section 1 and the second mobile conveyor section 2 and attached to the first mobile conveyor frame 1a and the second mobile conveyor frame 2a.

[0023]FIG. 3A depicts an exemplary embodiment of a first portion 20 of the connection device 10. The first portion 20 of the connection device 10 may be connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com