Connecting element for connecting a blade to the hub in an industrial axial fan, and blade system comprising said connecting element

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

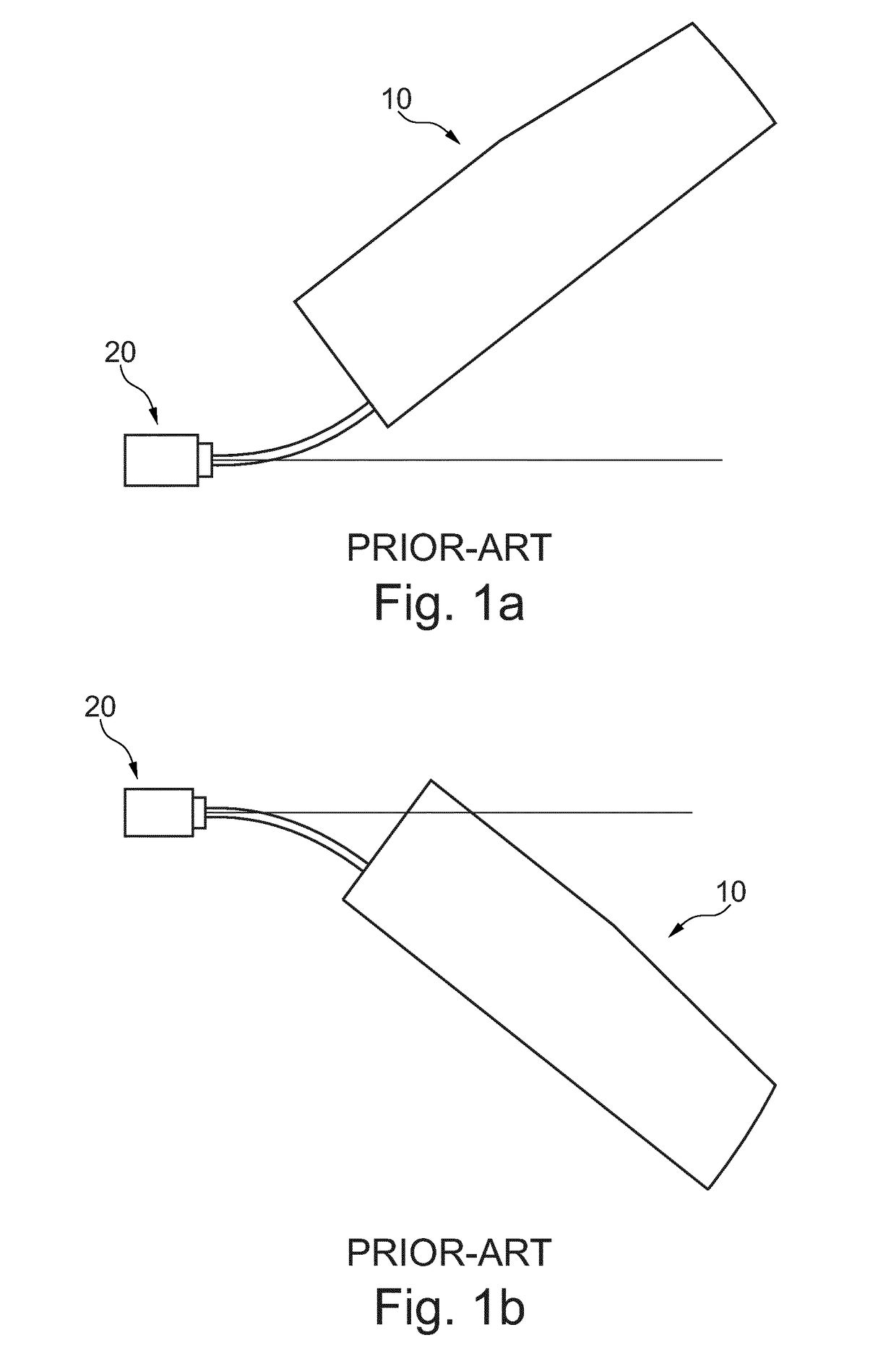

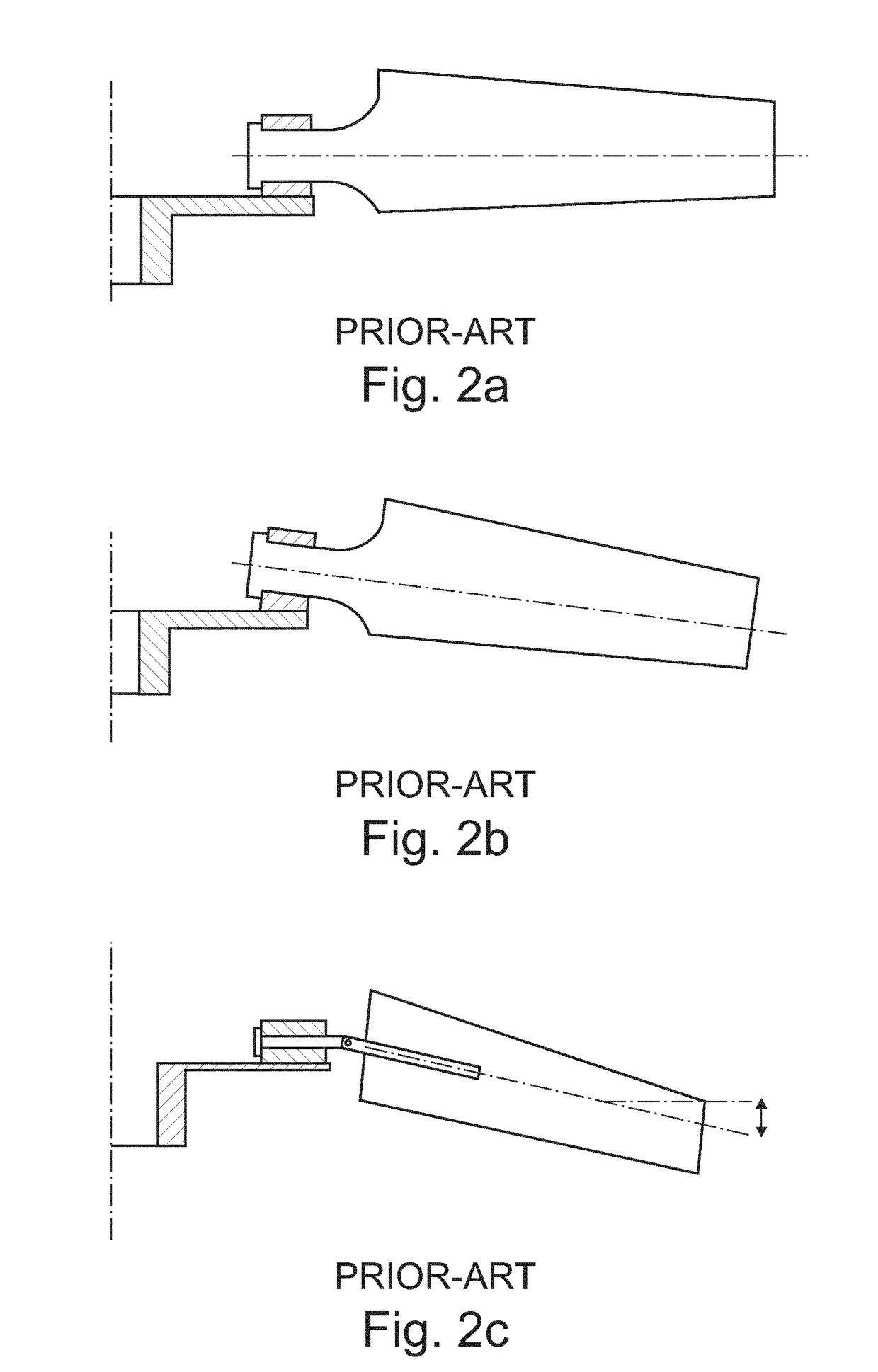

[0090]With reference to the above mentioned Figures, the main task of the present invention is to provide a connecting element for connecting the airfoil profile to the hub of an industrial axial fan.

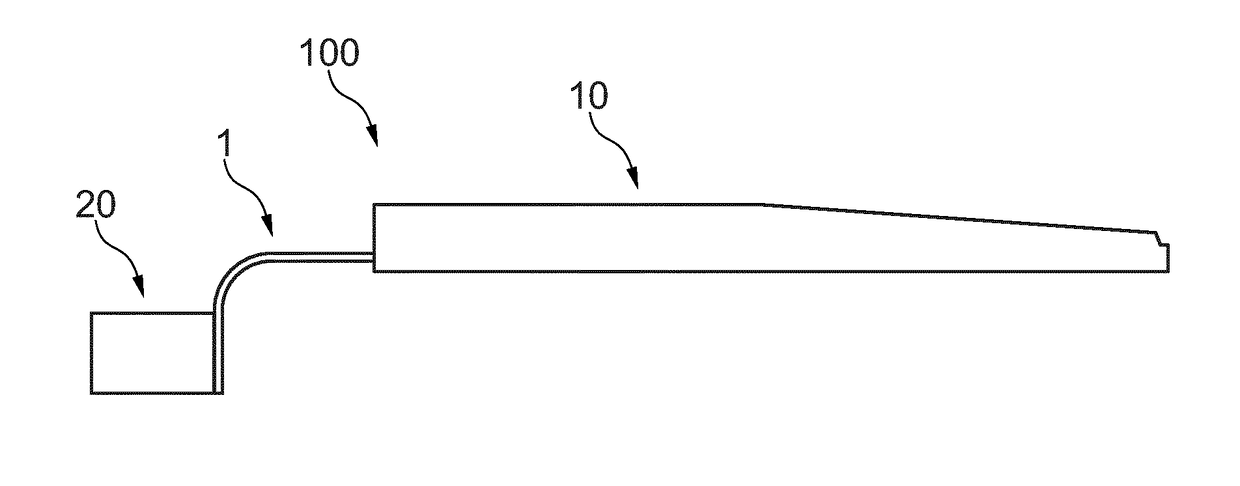

[0091]With reference to the above, the present invention concerns a connecting element 1 consisting of an extremely simple element, see for example FIGS. 5 to 7, having essentially a rectangular cross-section and a “L” shaped longitudinal-section comprising a first part 1a having a substantially straight develop and a second part 1b having a straight develop, said first 1a and second 1b part being connected by a linking part 1c presenting a curvature radius so that said first 1a and second 1b parts lie on substantially perpendicular planes.

[0092]Said first part 1a of the L-shaped profile, which is the shorter part, is apt to be connected to the hub 20 while said second part 1b, which is the longer part, is apt to be connected to the airfoil profile 10, said link part 1c connecting said ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com