Multi-fluid, high pressure, modular pump

a high-pressure, modular technology, applied in the direction of pump control, piston pump, borehole/well accessories, etc., can solve the problems of high-pressure pumps such as sub-sea pumps, having to operate in extremely difficult environments, and requiring expensive repair or replacement,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

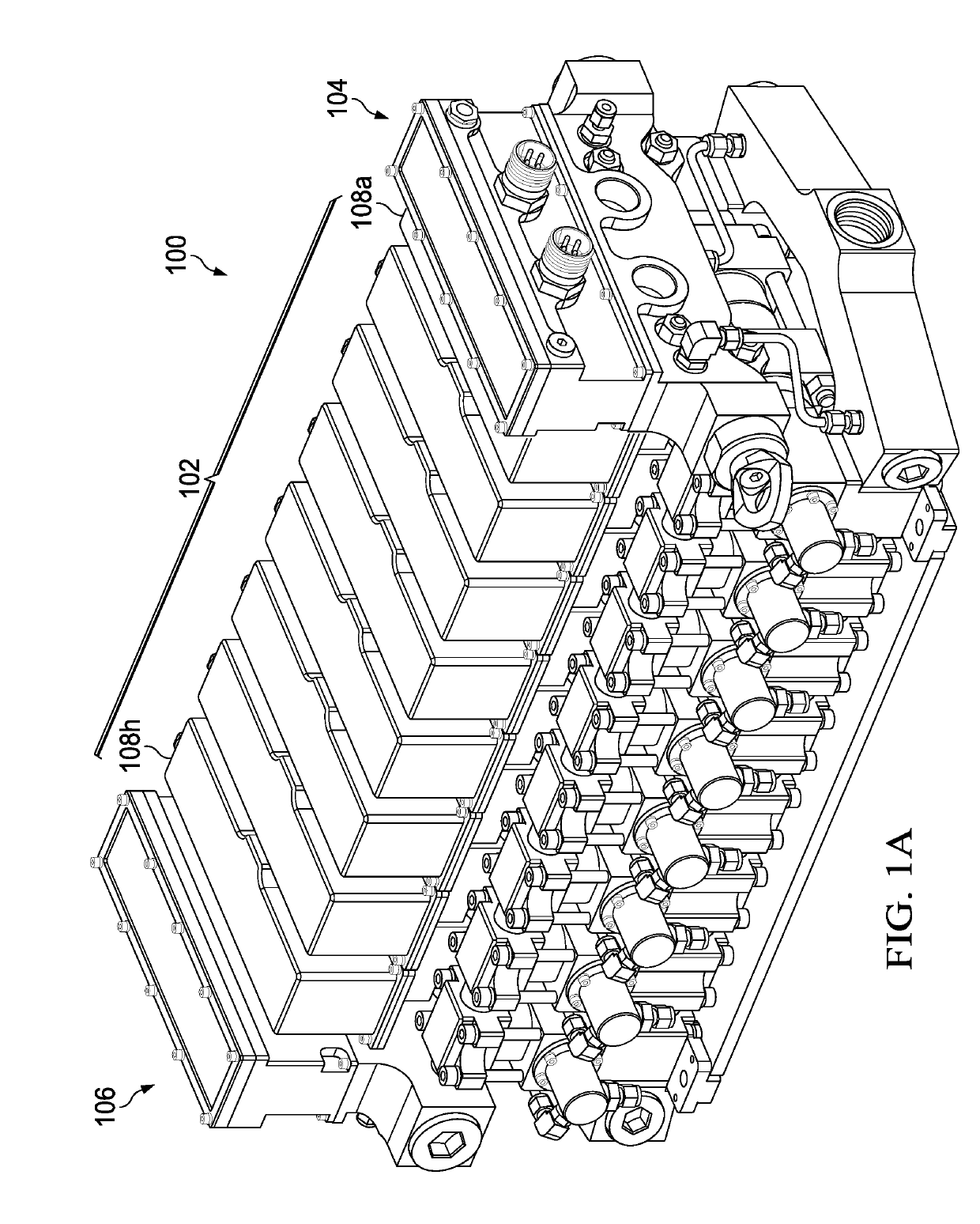

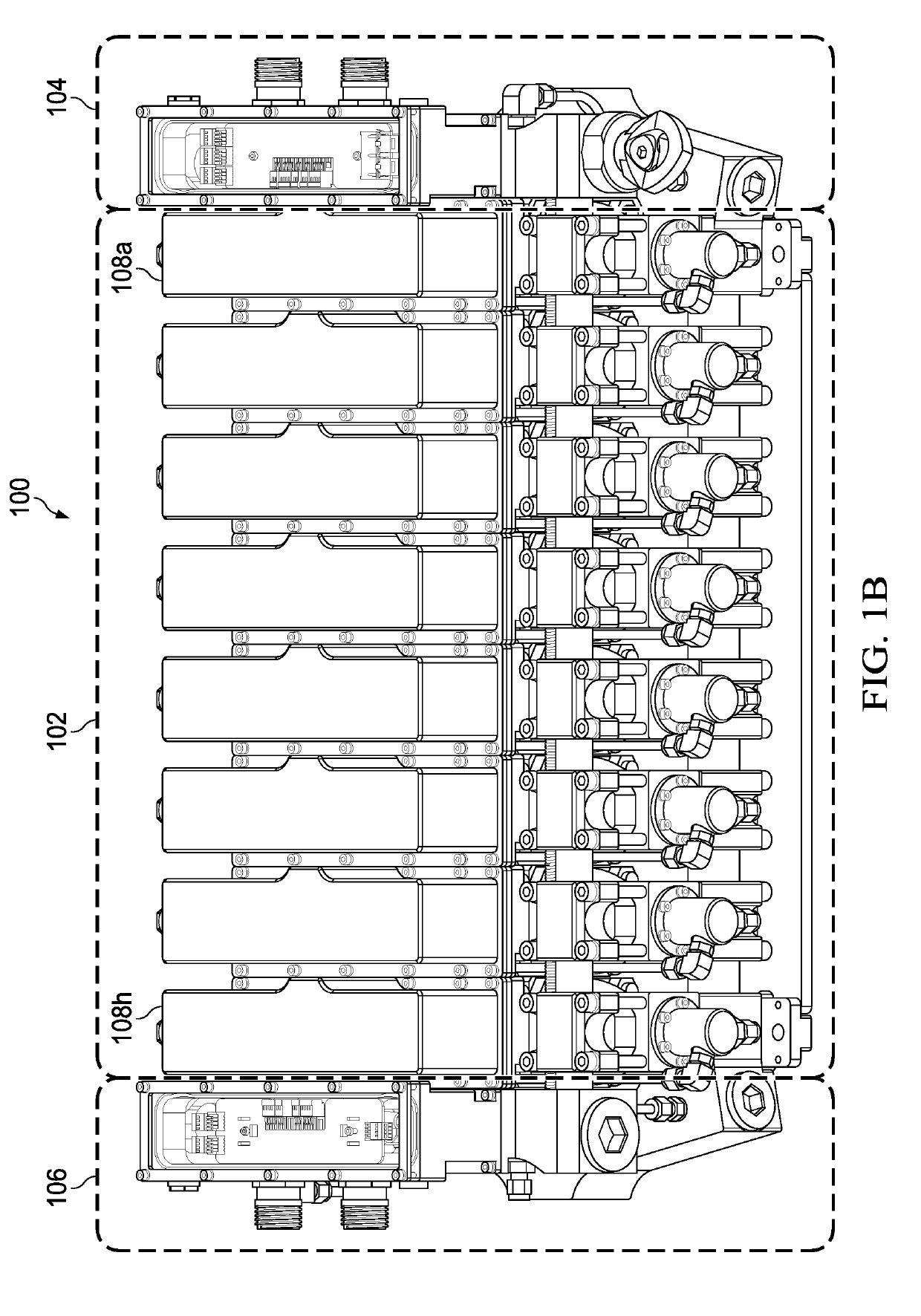

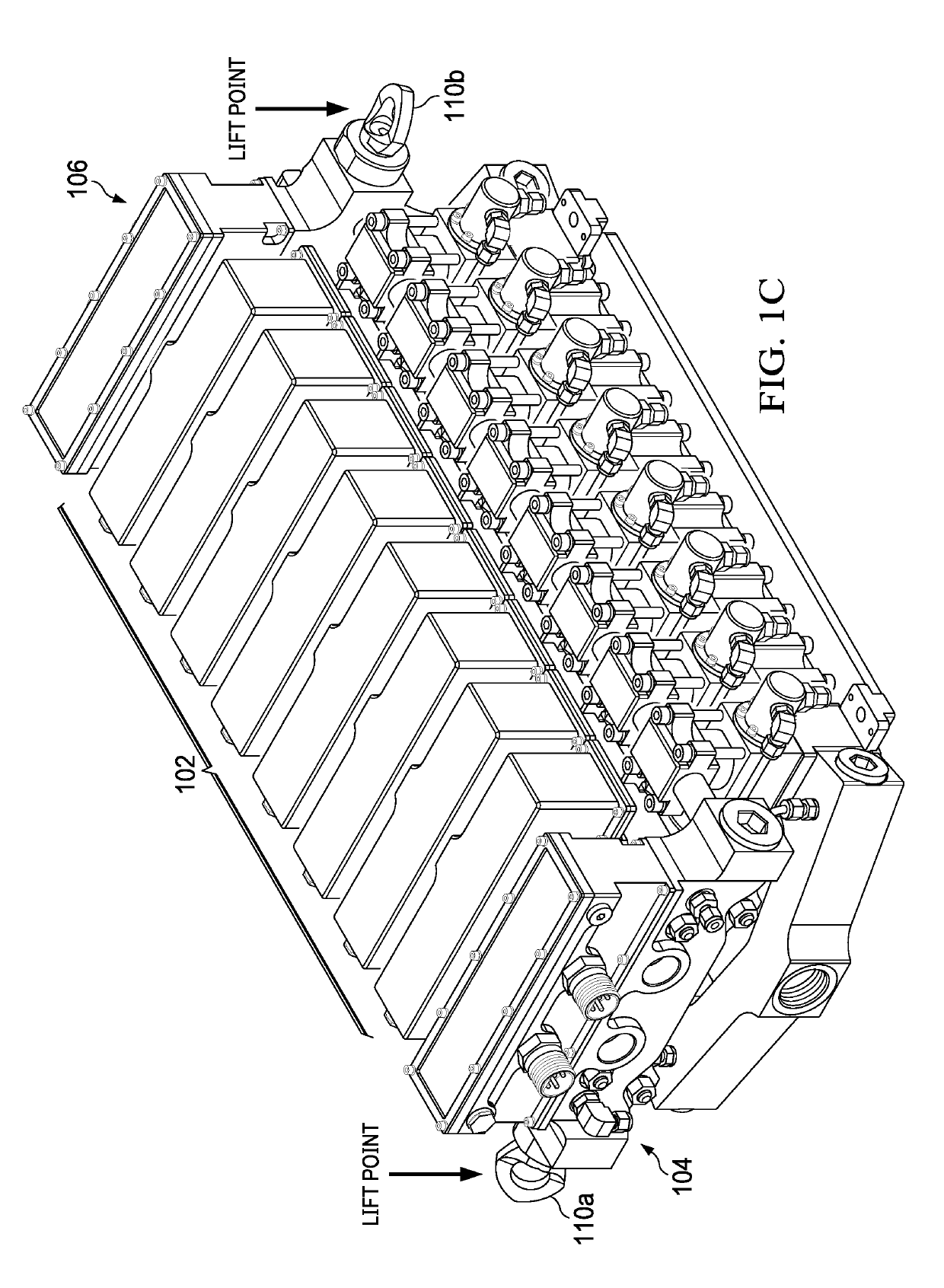

[0019]With regard to FIG. 1A, an illustration of an illustrative multi-fluid, high-pressure modular pump 100 is shown. The modular pump 100 may include a pump section 102 along with a primary connection section 104 and secondary connection section 106. The pump section 102 may include multiple sub-pumps 108a-108h (collectively 108) that are used to pump fluid. As shown, the pump section 102 includes eight sub-pumps 108, but it should be understood that two or more sub-pumps may be utilized to provide the functionality of a modular pump in accordance with the principles described herein. Each of the sub-pumps 108 may be connected to one another, as further described herein. The number of sub-pumps to be used is generally based on an amount and type fluid to be pumped, and available power (e.g., hydraulic power), and output needs (e.g., flow, pressure). The pump 100 may be pressure compensated by inclusion of internal fluid, such as oil, so as to be suitable for use at 4000 meter wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com