Stun grenade and method for production thereof

a technology of grenade and grenade shell, which is applied in the field of grenade shell, can solve the problems of fragment formation, ineffective effect charge, and risk of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

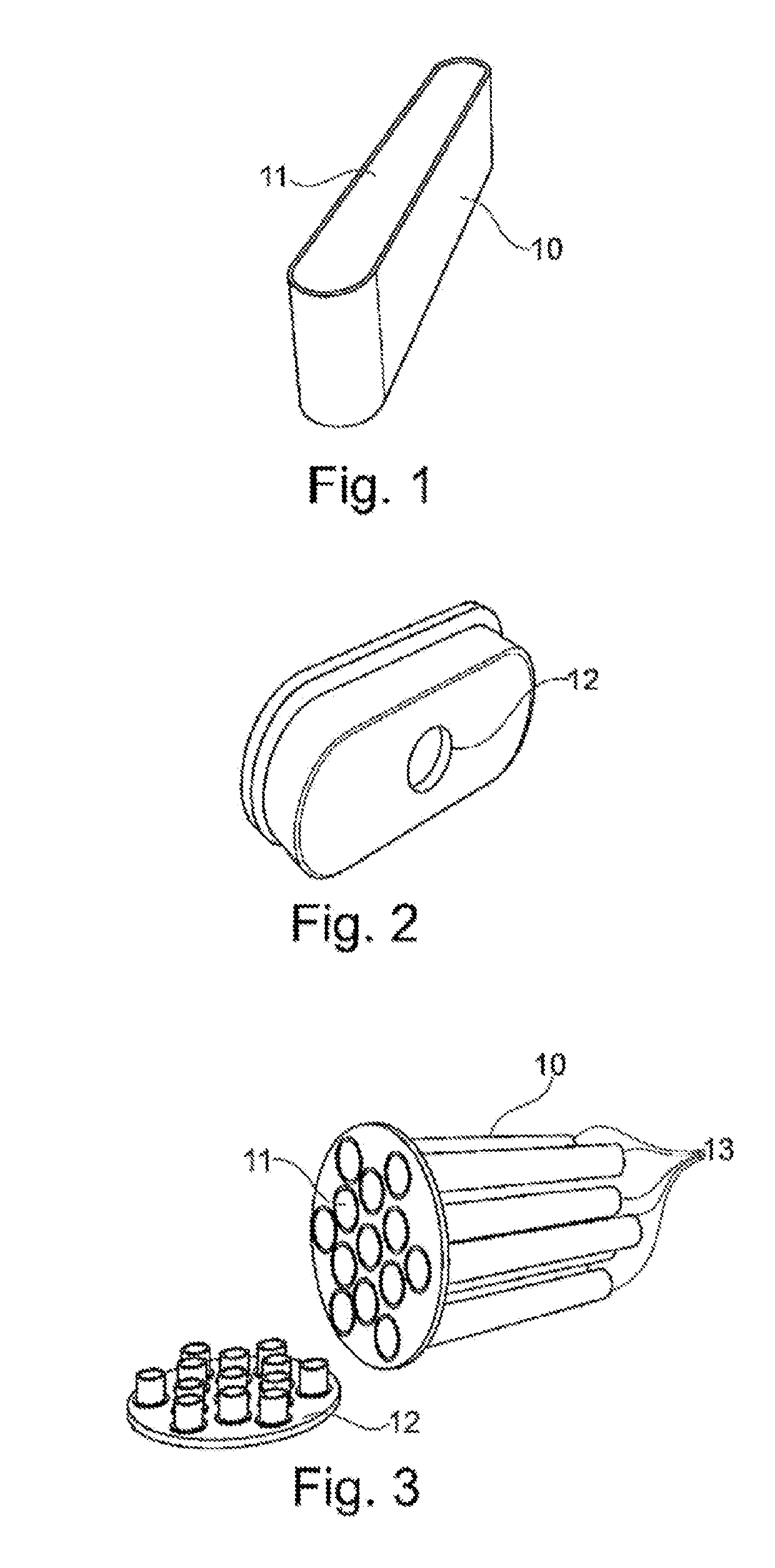

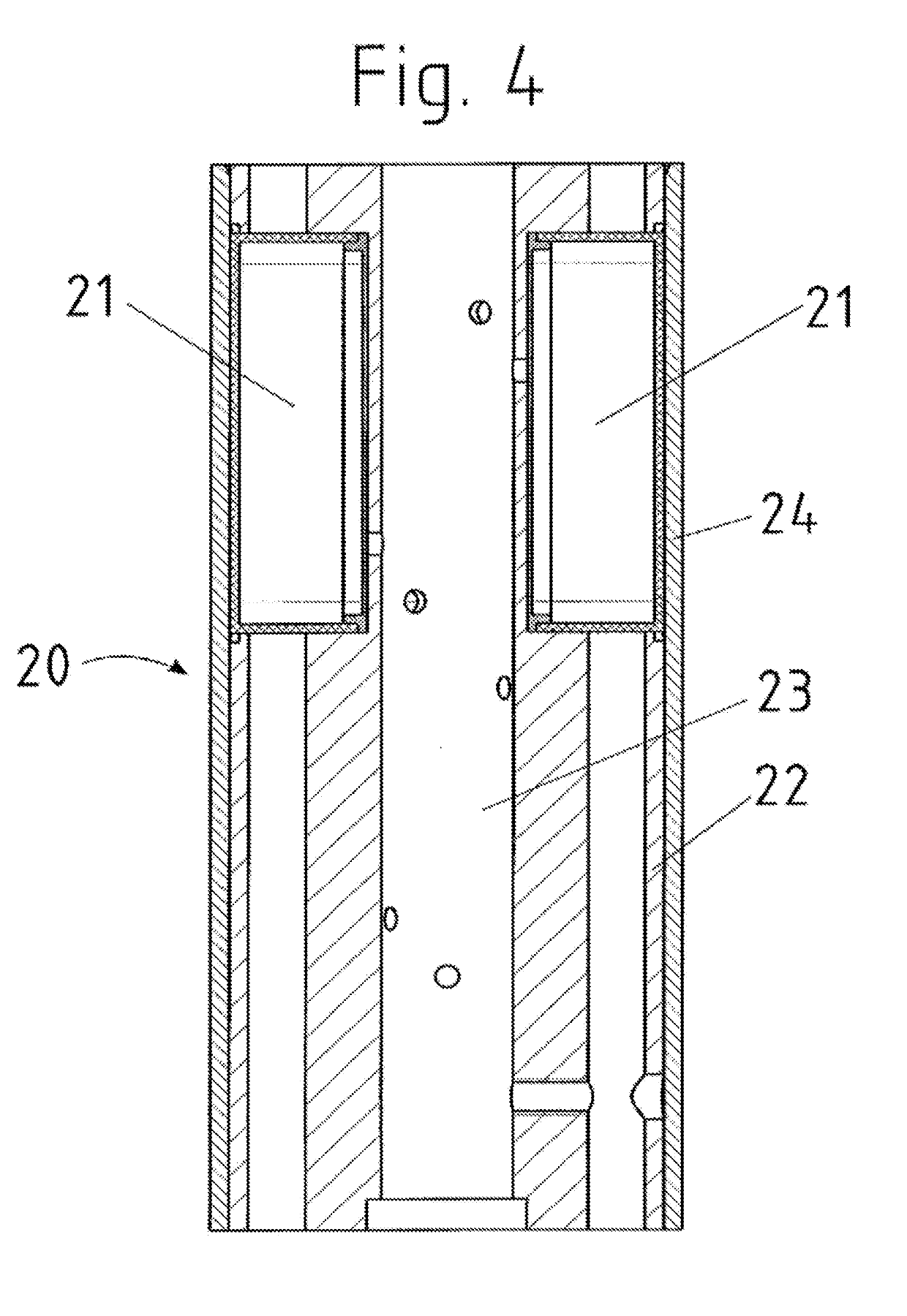

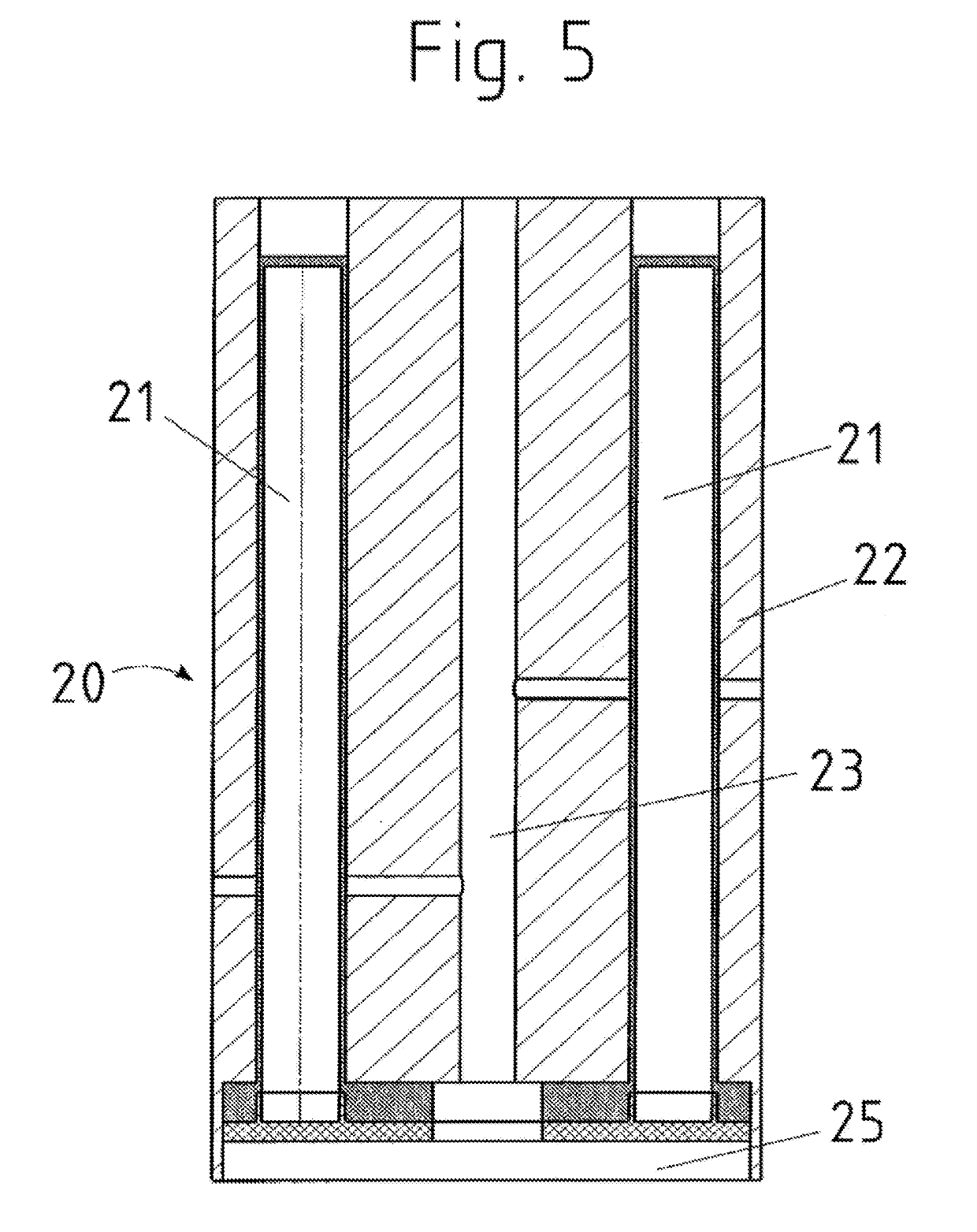

[0038]FIG. 1 shows a bowl as an unclosed flash charge container 10 according to the invention as a separate container, which has an opening 11 toward the upper side. Through this opening 11, the flash charge container 10 can be filled with an effect charge. It is likewise possible to put multiple effect charges into a flash charge container 10. In this case, multiple effects can be triggered with a time offset as a flash charge container 10 burns up.

[0039]The flash charge containers 10 are produced separately from the main bodies 22 of the stun grenades 20 and can also be stored separately from the main bodies 22 of the stun grenades 20 until final assembly in the event of use.

[0040]FIG. 2 shows a cover 12 according to the invention for sealing off the flash charge container 10. Here, the flash charge container comprises a bowl and a cover. Following filling of the bowl with the effect charges, said bowl is closed in a watertight manner by a cover 12. The water-tightness is a precon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com