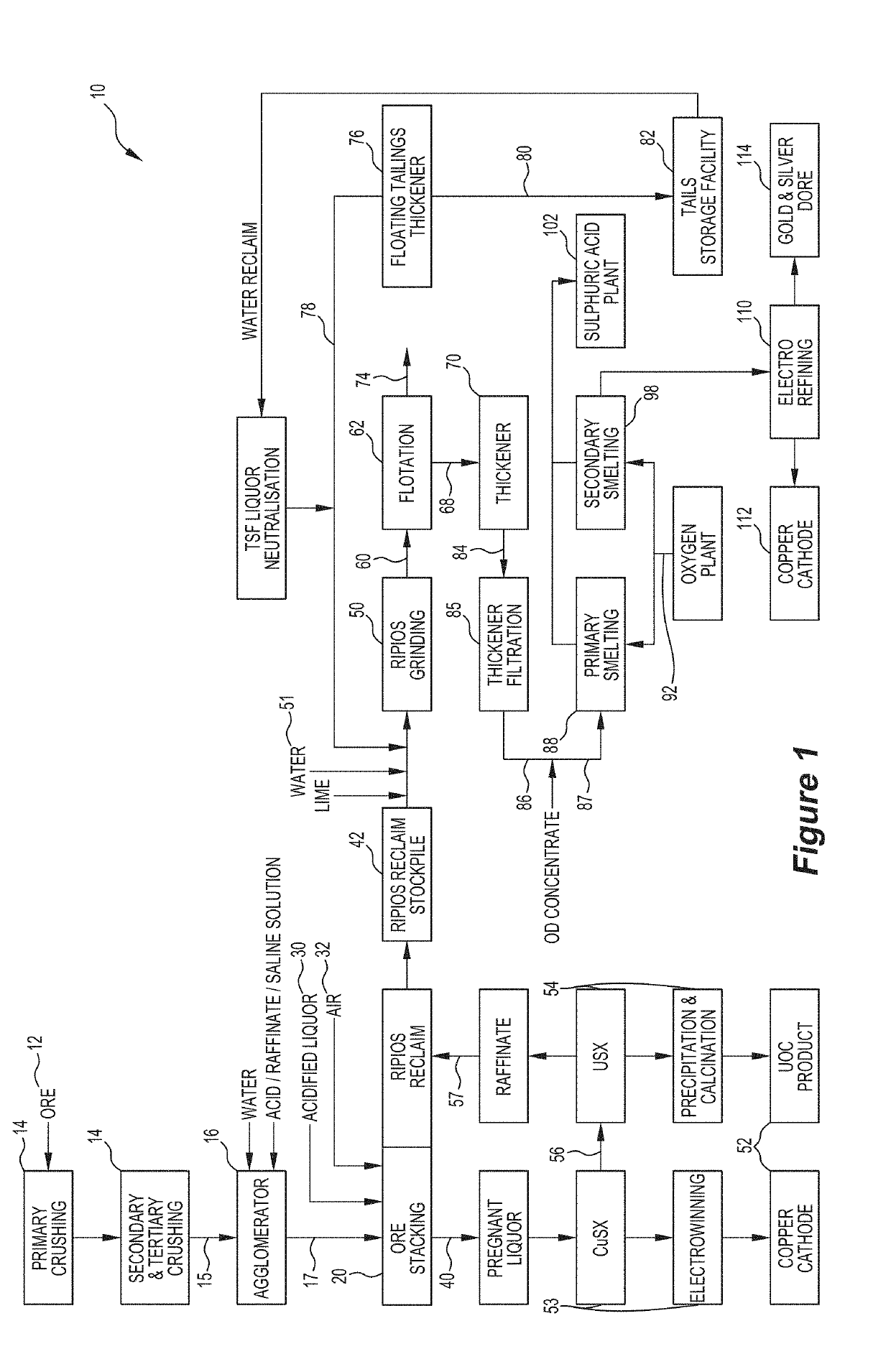

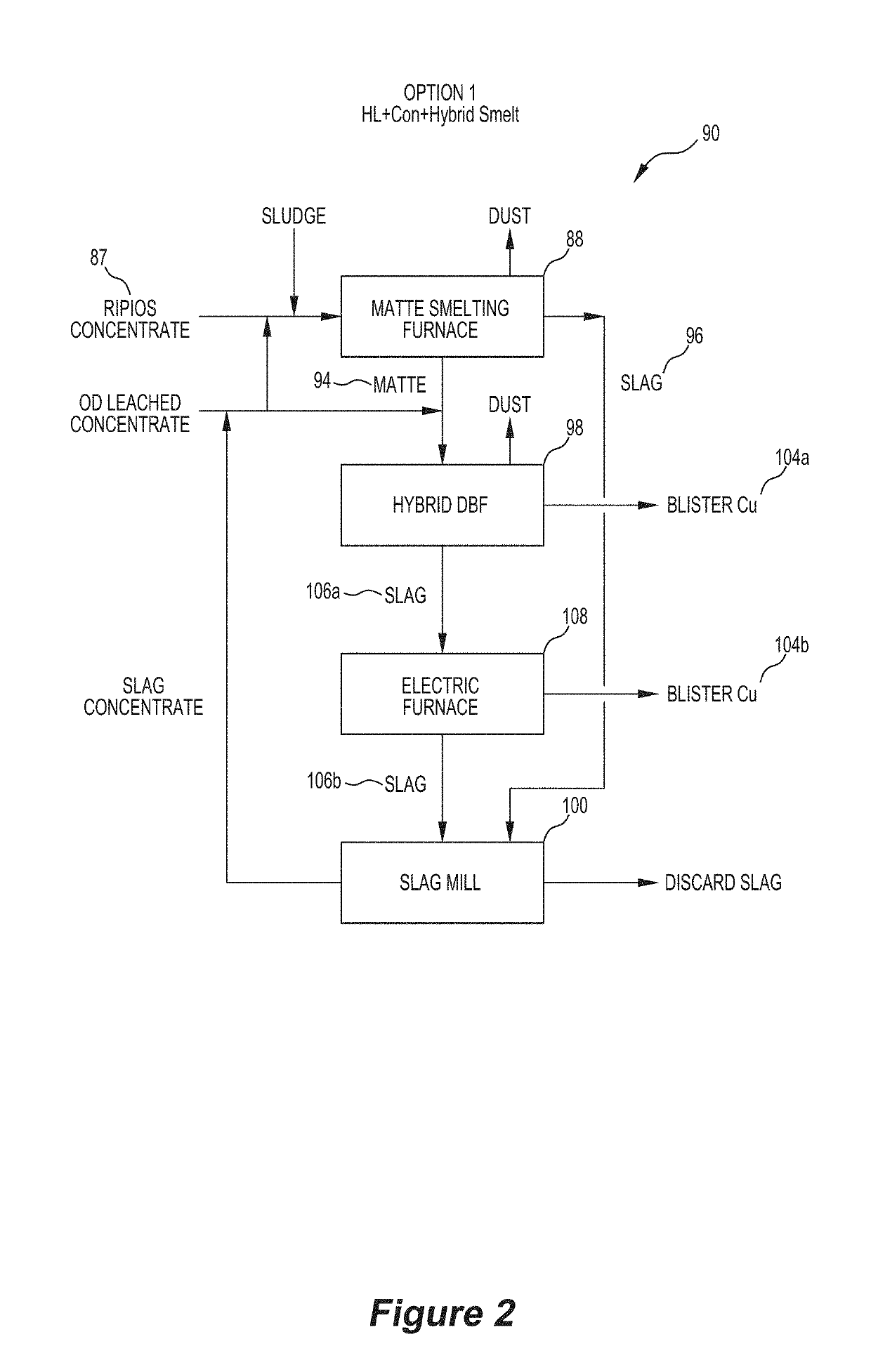

Integrated hydrometallurgical and pyrometallurgical method for processing ore

a technology of hydrometallurgical and pyrometallurgical methods, applied in the direction of improving process efficiency, etc., can solve the problems of reducing the availability and continuity of the overall plant, complex treatment of ore, and lack of expandability, and achieve the effect of convenient drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

Heap Leaching and Flotation of Ripios

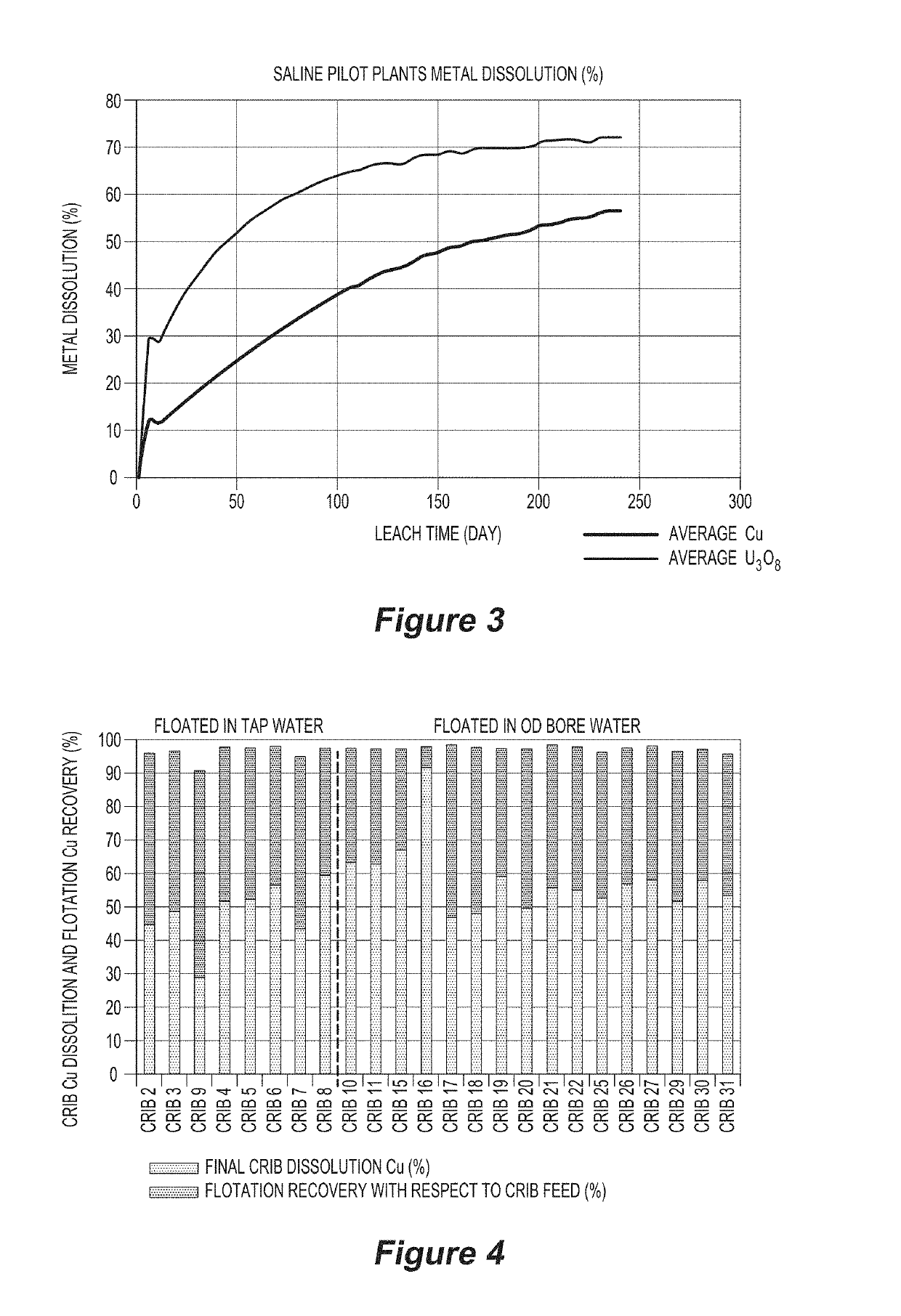

[0137]Ore samples, having a diverse range of mineralogy that reflected the actual range of ore mineralogy at Olympic Dam, were subjected to heap leaching (ie, step (a) of the disclosed process) in columns using an iron containing, acidic saline leaching solution in the presence of air. The Cu:S ratios of the ore samples ranged from approximately 3 to less than 1. The ore contained a number of iron containing minerals, such as siderite and chlorite, which provided a source of ferric in the leaching solution. The acid consumption of the samples also varied from high to low, reflecting the variation in gangue mineralogy. The U3O8 grade of the ore was variable ranging from approximately 200 ppm to 1,000 ppm.

[0138]The dissolution of copper and uranium was measured over time. FIG. 3 shows the results of these tests. The average dissolution (%) of U3O8 and Cu are plotted against time (days). The actual Cu and U extraction values ranged from 20% to 80% a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com