One-piece drink-through cup lid with a straw section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

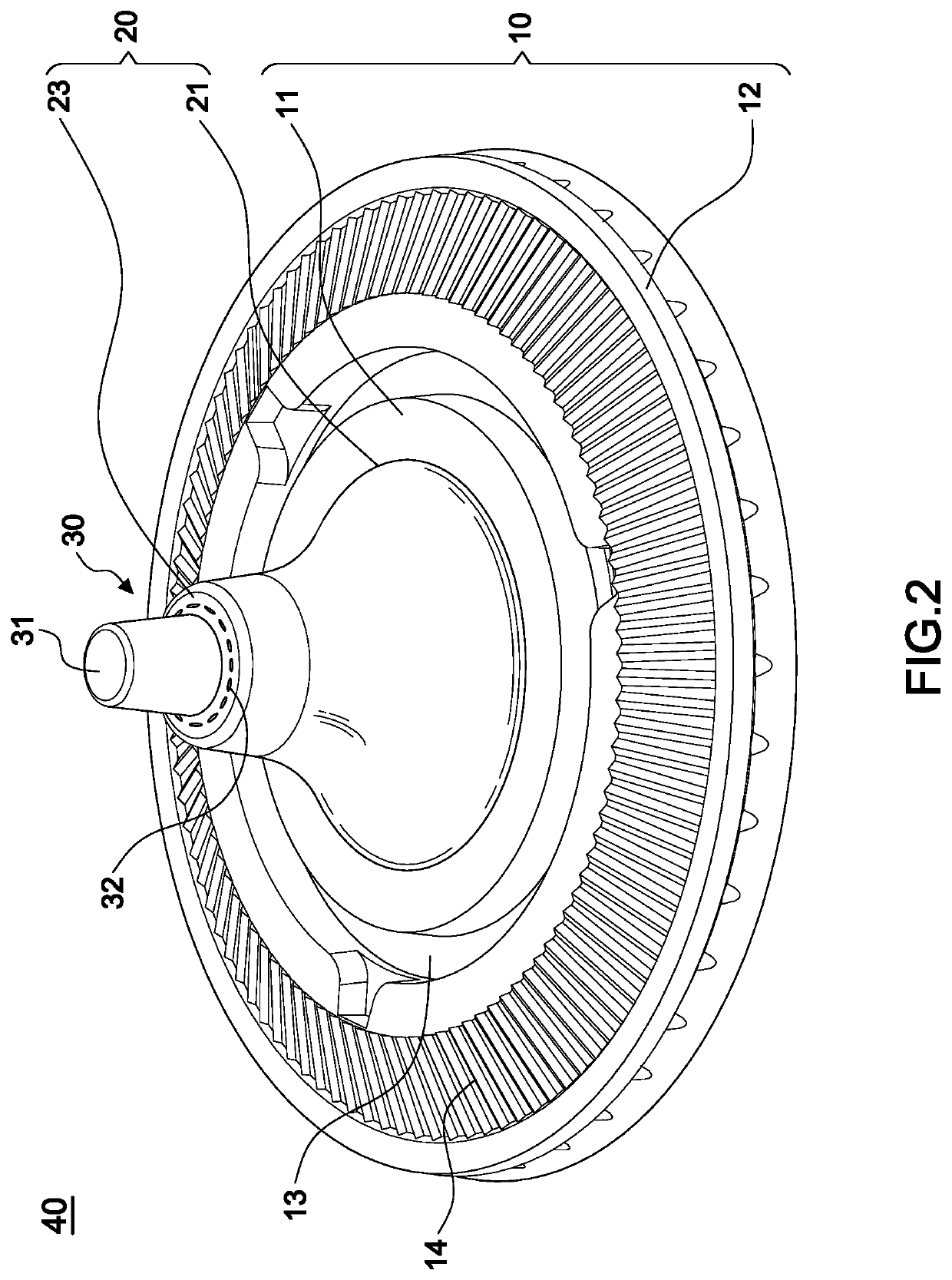

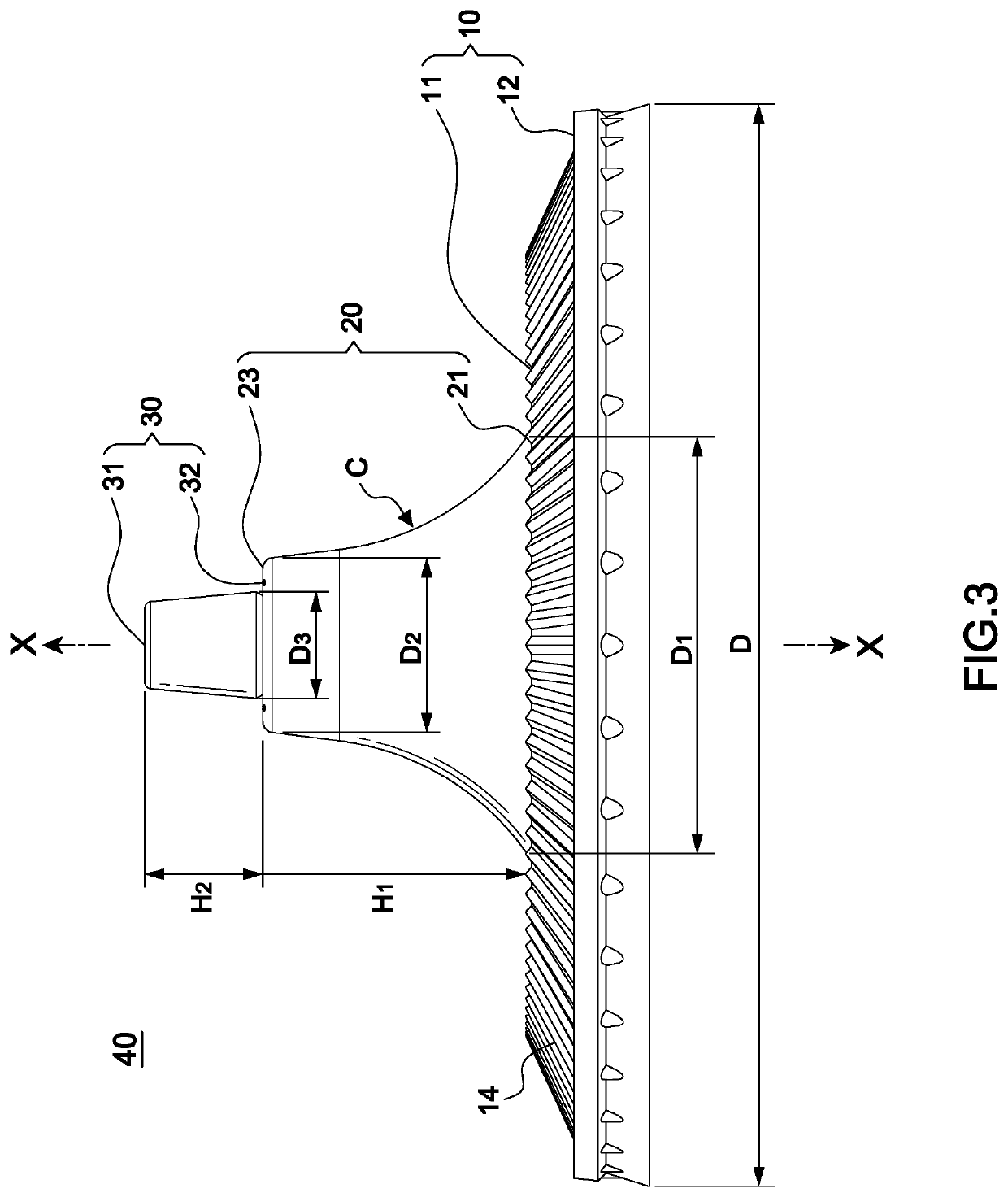

[0026]To further illustrate the features and structures of the drink-through cup lid, please referring to an embodiment in the following with reference to FIGS. 2-6B. A one-piece drink-through cup lid with a straw section 40 is designed for covering on a beverage cup 50. In the preferred embodiment, the one-piece drink-through cup lid with a straw section 40 mainly includes a cup lid 10, a conic section 20 and a detachable tube section 30 arranged on the conic section.

[0027]The cup lid 10 has a peripheral surface 11, a peripheral edge 12 extending from an outer edge of the peripheral surface 11, a circular depression 13 and a wavelike surface 14. Such structure can be commonly seen in conventional cup lids; however, the features of the present invention is that the conic section 20 is formed and protruding axially at a center of the peripheral surface 11 and has a bottom periphery 21 connecting to the peripheral surface 11 so as to form a first through hole 22 inside the conic secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com