Automated construction robot systems and methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

System Overview

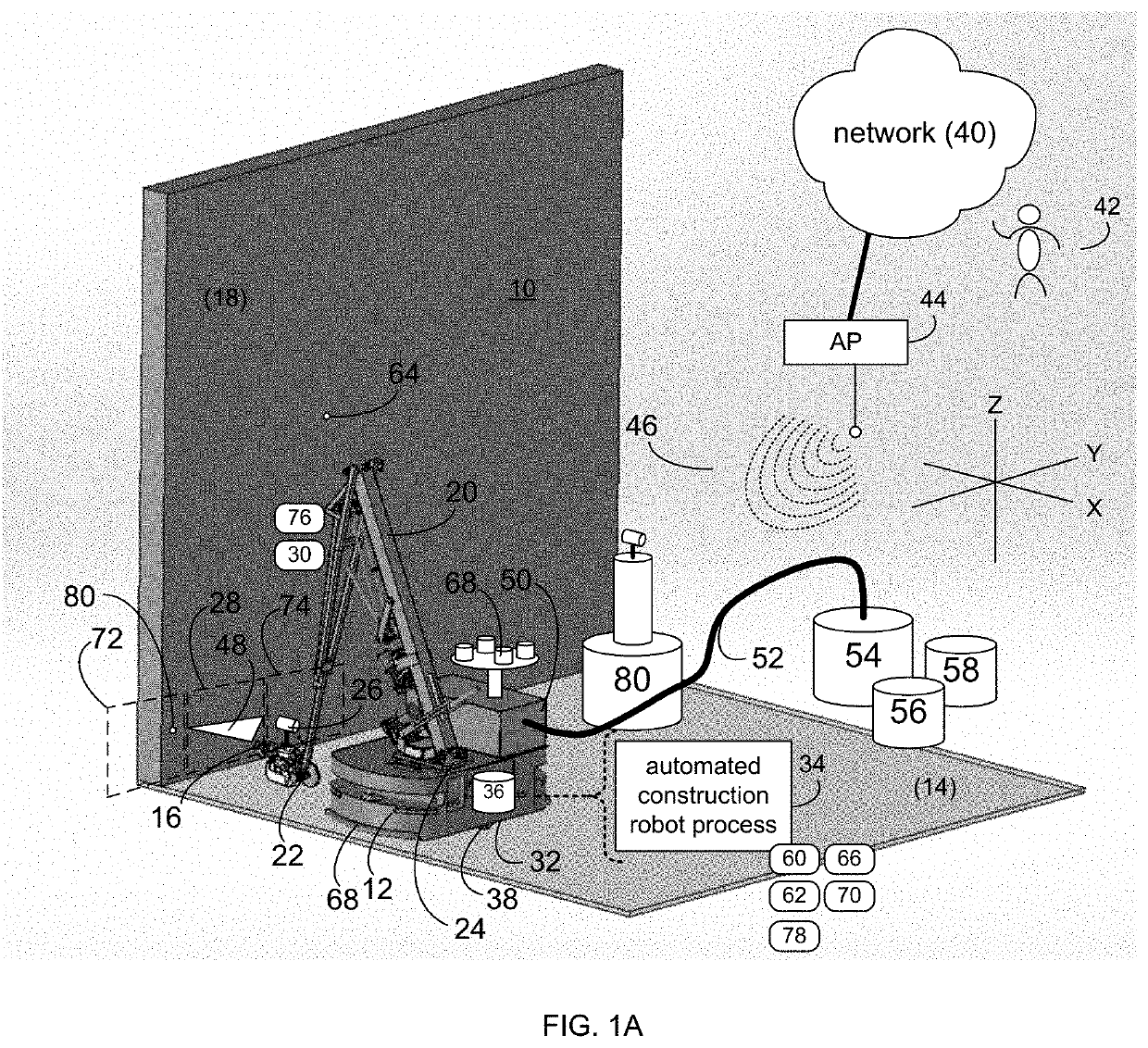

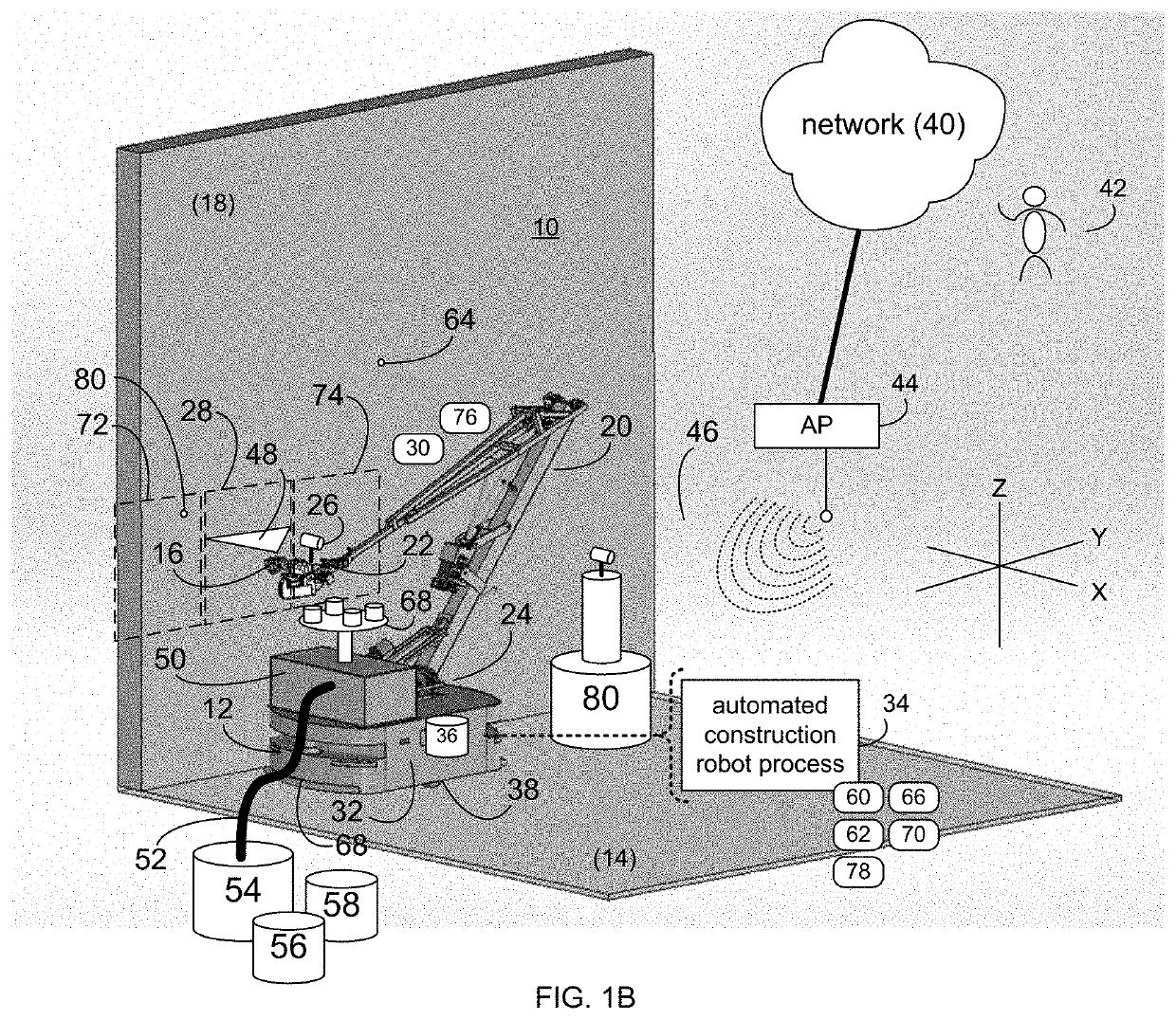

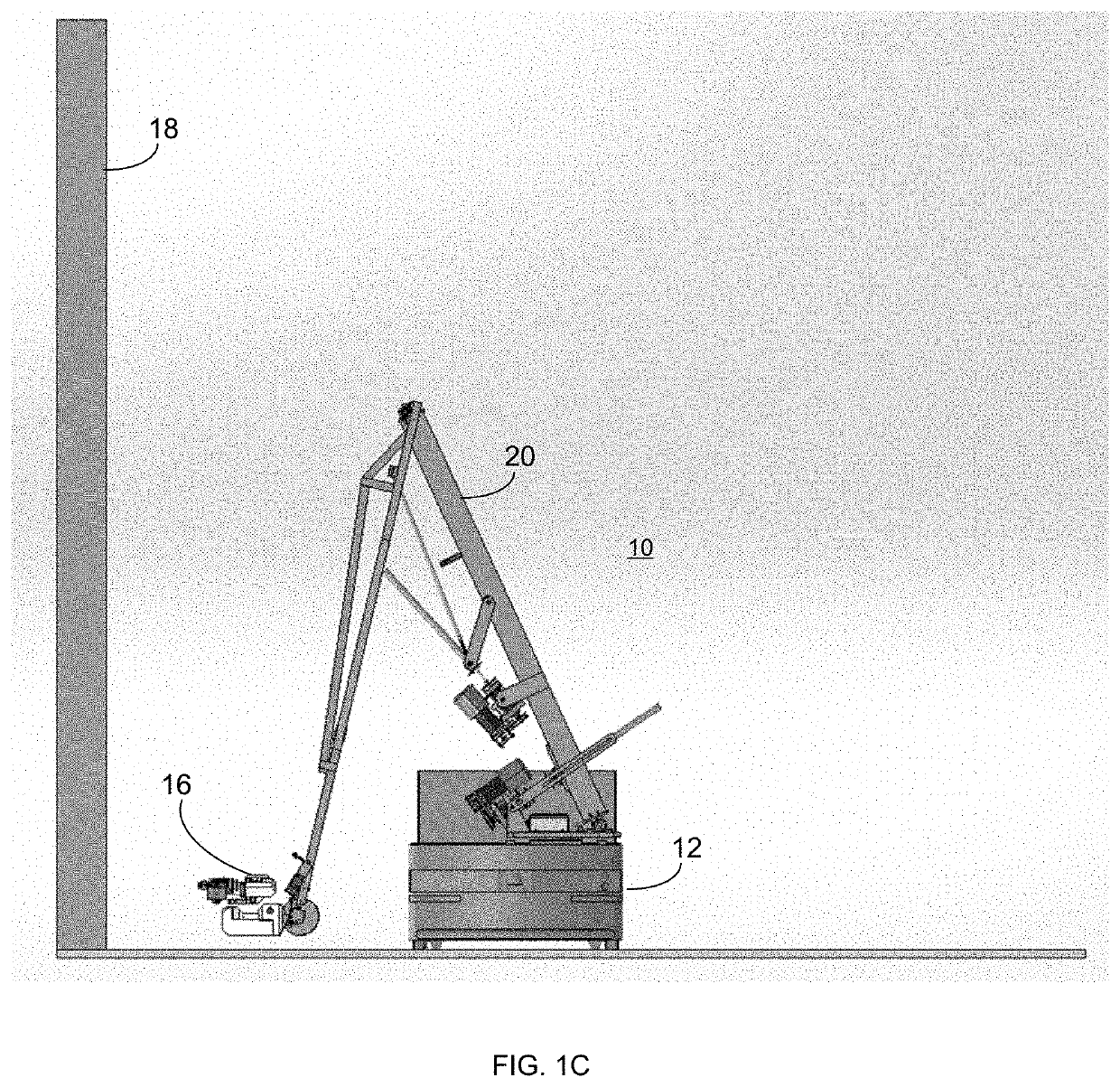

[0022]Referring to FIGS. 1A-1E, there is shown automated construction robot system 10, wherein automated construction robot system 10 may include mobile base assembly 12 configured to be displaceable within work area 14. Examples of mobile base assembly 12 may include any kind of base assembly that would allow for the movement of automated construction robot system 10 within work area 14. One example of mobile base assembly 12 may include but is not limited to a mobile base assembly that includes a plurality of wheels that allow for the movement of mobile base assembly 12 within work area 14, wherein such a wheeled mobile base assembly may be highly suitable for situations in which work area 14 is a smooth surface (e.g., a finished floor). Another example of mobile base assembly 12 may include but is not limited to a mobile base assembly that includes a plurality of tracks (not shown) that allow for the movement of mobile base assembly 12 within work area 14, wherein ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap