Aerosol product

a technology of aerosol and product, applied in the field of aerosol products, can solve the problems of inability to achieve optimal mist configuration, limited type and amount of liquefied gas, etc., and achieve the effect of simple structure and reducing limitations on applicable liquids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

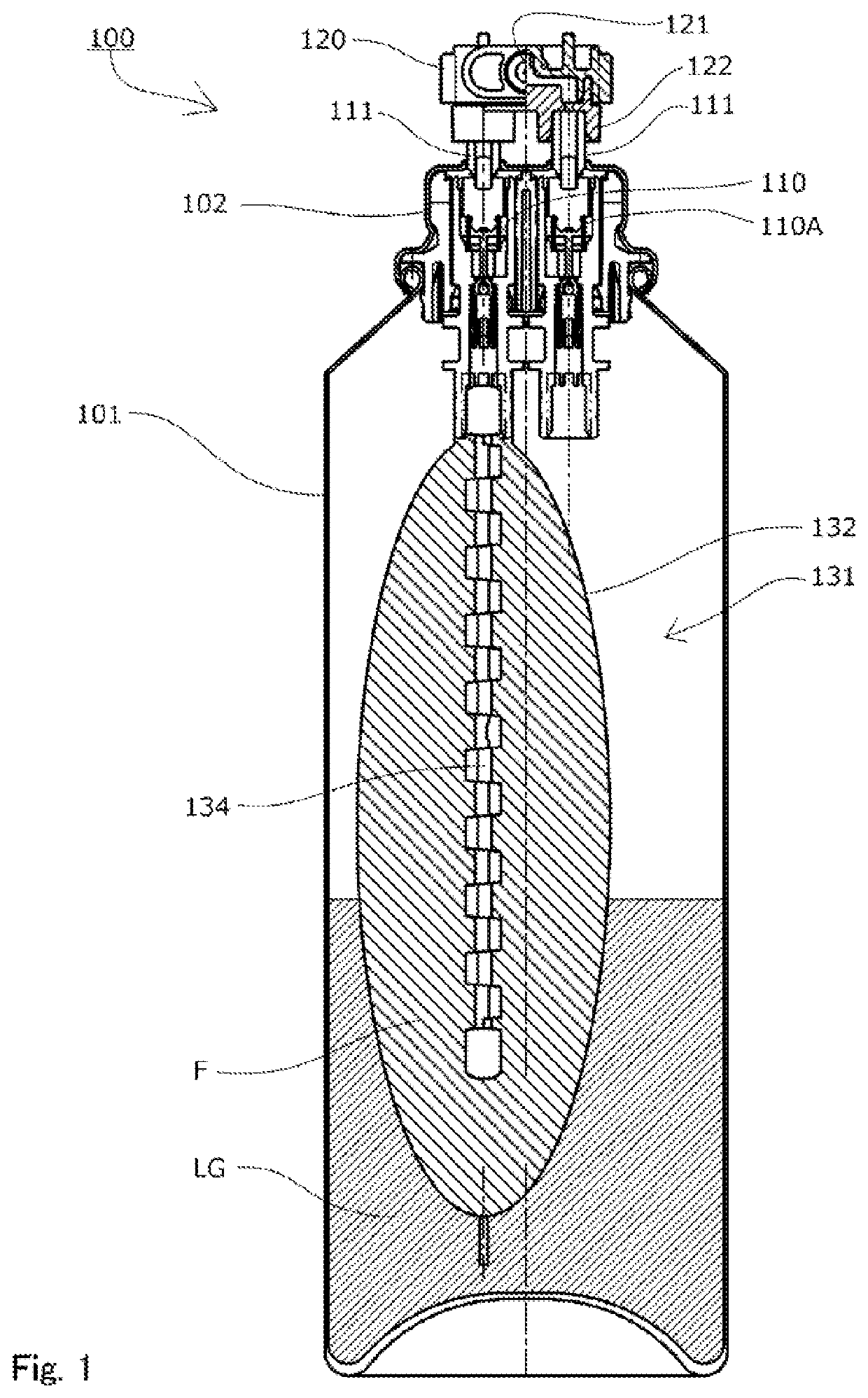

Image

Examples

example 1

[0036]Flow path diameter of the valve 110 for the content F: 0.35 mm

[0037]Flow path diameter of the gas phase valve 110A: 0.35 mm

[0038]Liquefied gas: HFO-1234ze

Example 2

[0039]Flow path diameter of the valve 110 for the content F: 2.00 mm

[0040]Flow path diameter of the gas phase valve 110A: 0.35 mm

[0041]Liquefied gas: HFO-1234ze

[0042]A common one-valve aerosol spray container was used as comparative examples.

example 2

[0052]Table 2 shows the test results of the aerosol product 100 according to the first embodiment using water as the content F, with varying flow path diameters of the valve 110.

TABLE 2Flow pathAveragediameter particleEjection(mm)Area ratioGassizepressureConditionLiquidGasLiquid / gastype(μm)(g)10.32 2%HFO-NotNot1234zeejectablemeasurable10.32 2%LPG28.132.10.1510.32 2%LPGNotNot0.39ejectablemeasurable10.32 2%DME15.447.220.352 3%HFO-19.635.91234ze20.352 3%LPG17.146.20.3930.42 4%HFO-20.45.91234ze40.452 5%HFO-22.165.61234ze50.52 6%HFO-21.065.21234ze622 100%HFO-33.945.51234ze622 100%LPG35.13.10.15622 100%LPG22.486.50.39622 100%DME55.496.2720.51600%HFO-33.765.91234ze820.353265%HFO-41.226.41234ze920.34444%HFO-58.065.91234ze

[0053]In Condition 1 to Condition 6, the flow path diameter of the gas phase valve 110A was 2.00 mm, while the flow path diameter of the valve 110 for the content F was increased stepwise, i.e., 0.3 mm, 0.35 mm, 0.4 mm, 0.45 mm, 0.5 mm, and 2.00 mm.

[0054]In Conditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com