Cleaner head

a cleaning head and head technology, applied in the direction of suction cleaners, climate sustainability, sustainable buildings, etc., can solve the problems of reducing the cleaning effect, and occupying an area that is undetected, so as to reduce the area occupied by the floor, maintain the cleaning effect, and minimize the effect of resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]Hereinafter, an explanation on a cleaner head according to the present invention will be in detail given with reference to the attached drawings.

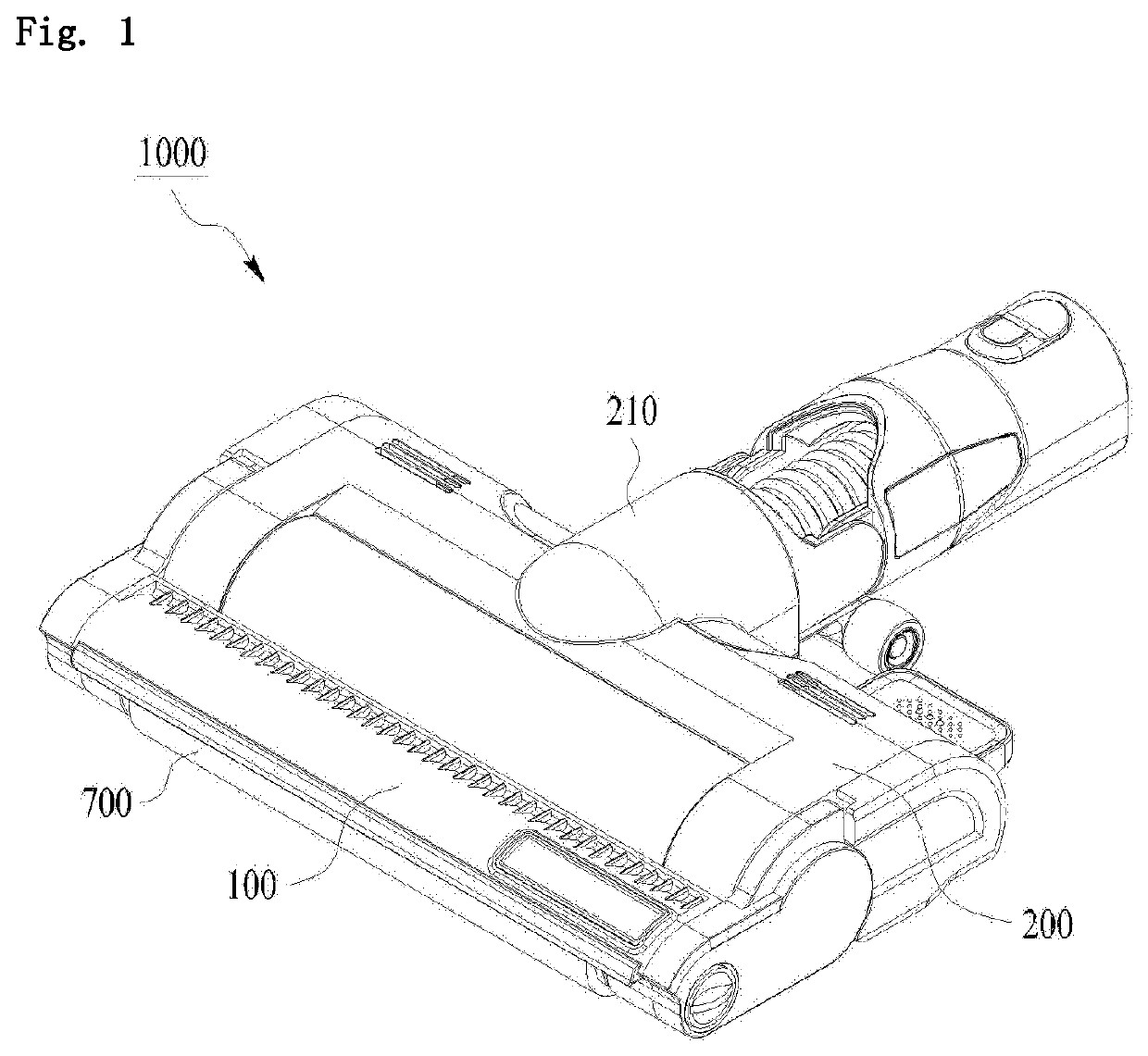

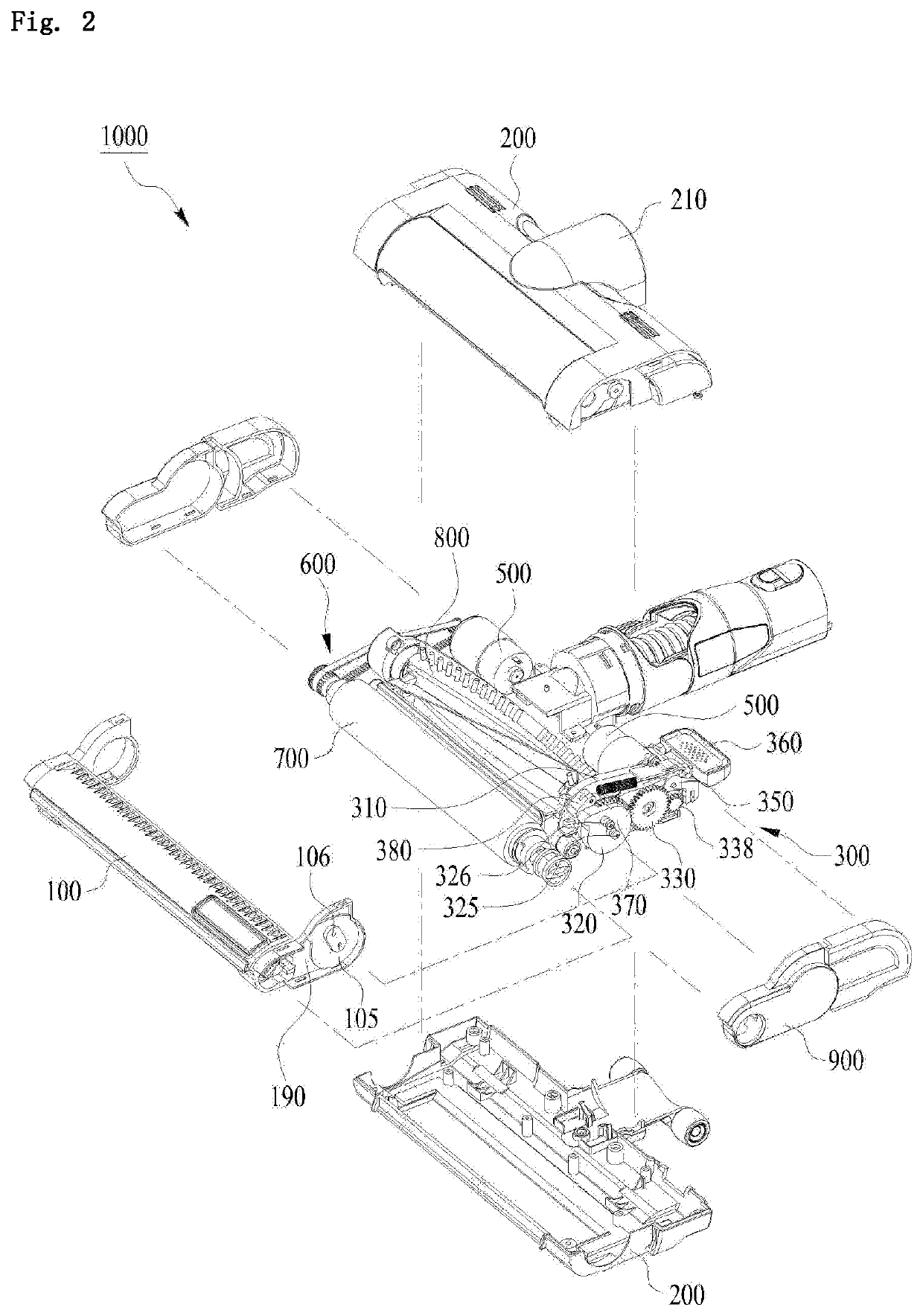

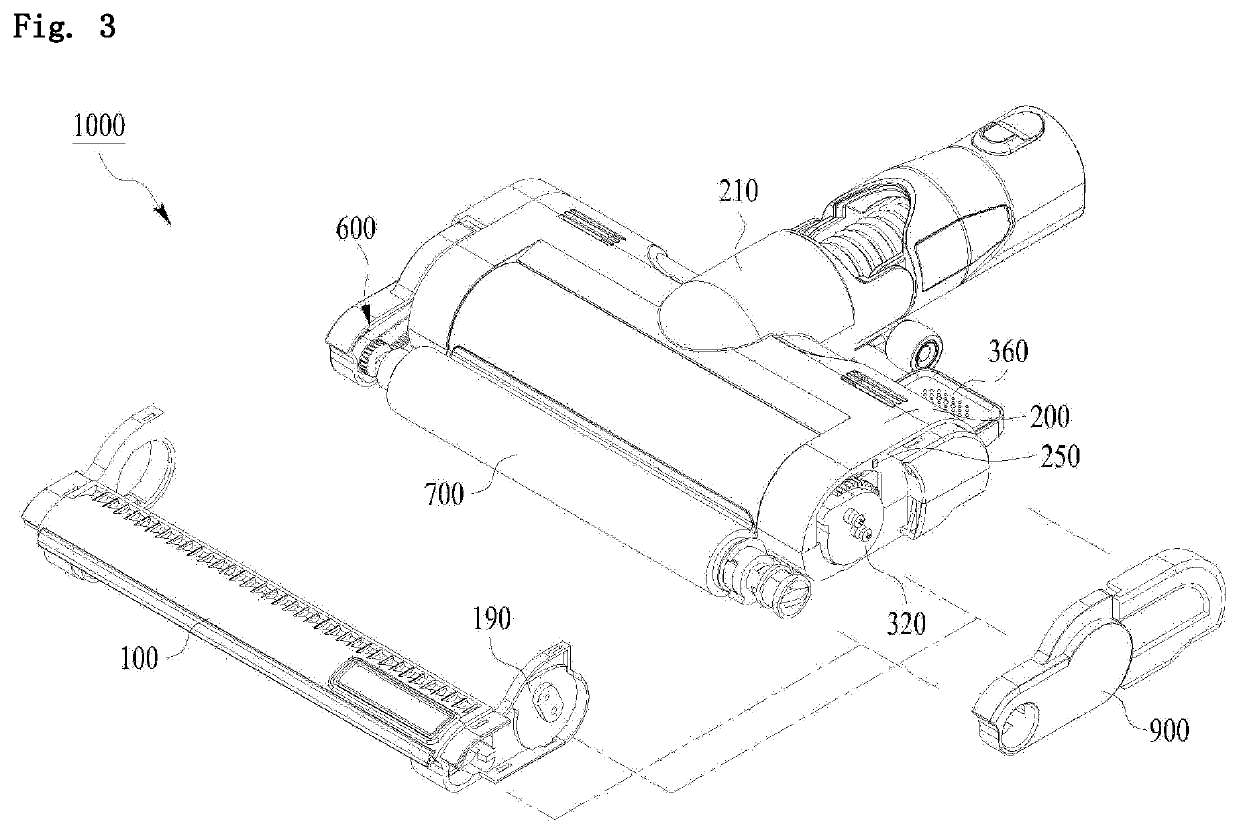

[0041]As shown in FIGS. 1 to 4, a cleaner head 1000 according to the present invention includes: a front housing 100 and a rear housing 200 disposed side by side on front and rear sides thereof respectively, the rear housing 200 having an air outlet 210 formed thereon; a front brush 700 rotatably disposed on the front housing 100 in such a manner as to be exposed from the underside of the front housing 100; a rear brush 800 rotatably disposed the rear housing 200 in such a manner as to be exposed from the underside of the rear housing 200; driving motors 500 built in the rear housing 200 to rotate the front brush 700 and the rear brush 800 through a power transmission mechanism 600; a lifting unit 300 disposed on one side of the rear housing 200 to move up and down the front housing 100 with respect to the rear housing 200 in a hinged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com