Holding structure for cable

a technology of holding structure and cable, which is applied in the direction of cables, insulated conductors, conductors, etc., can solve the problems of affecting the sealing effect of portions, affecting the sealing effect, and taking time, and achieve the effect of reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

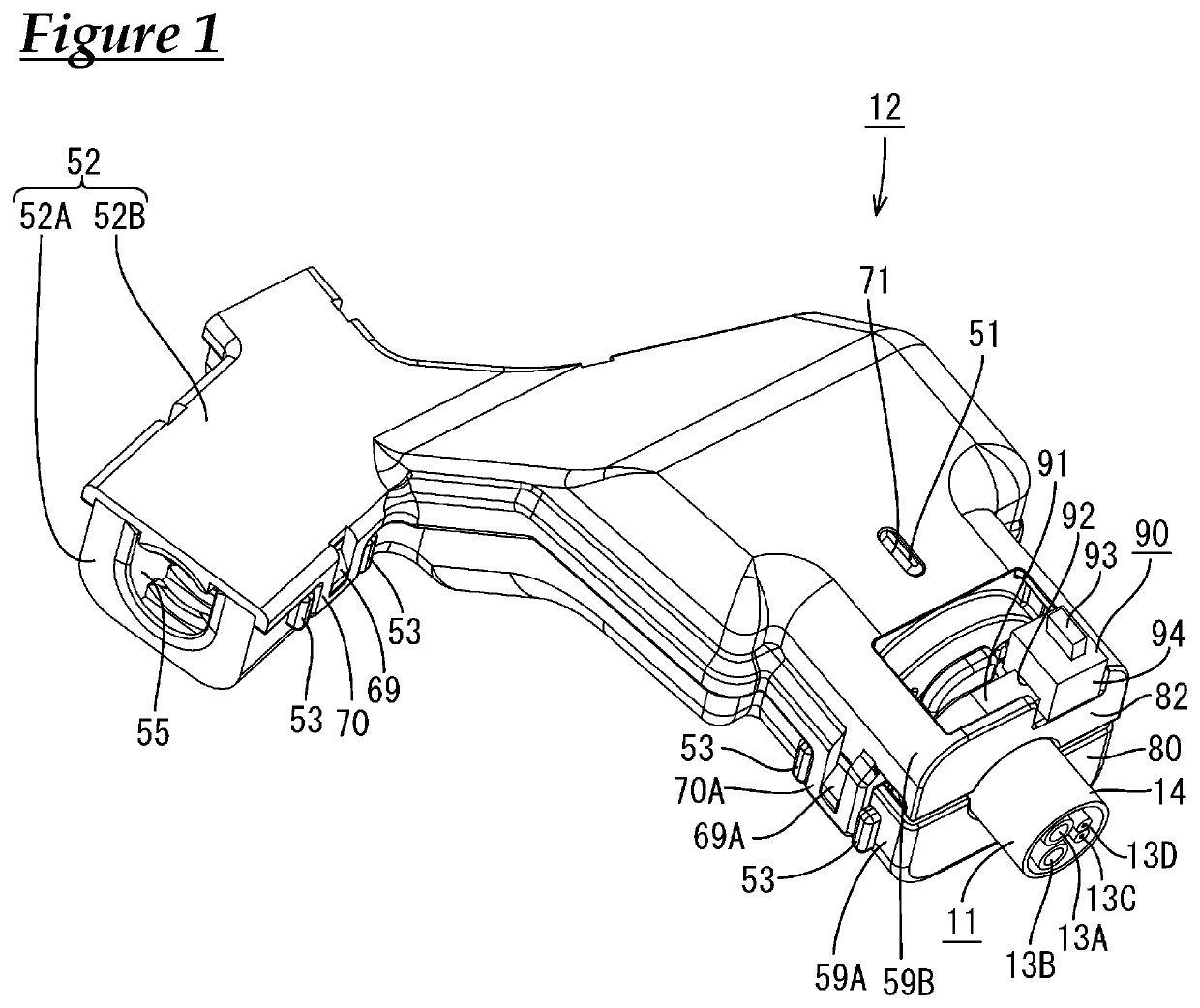

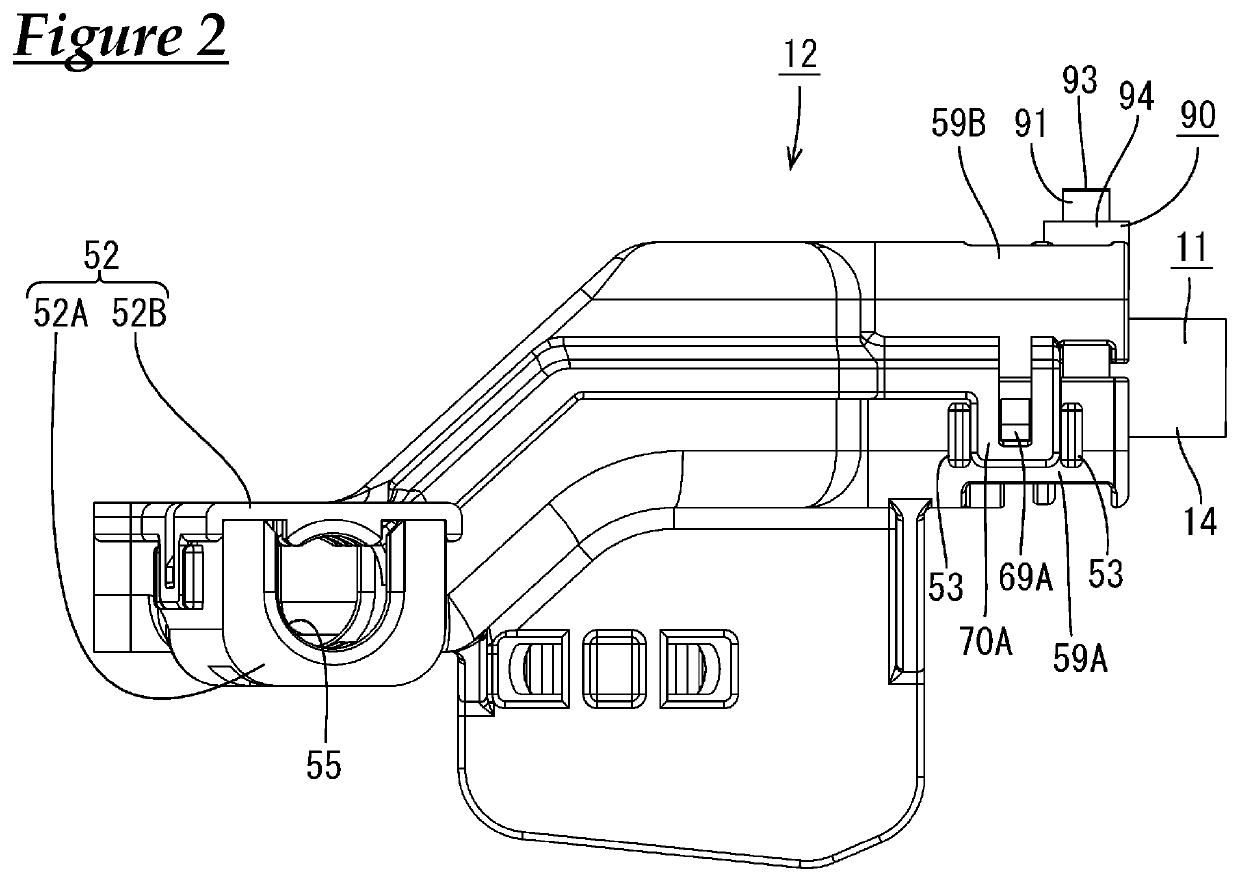

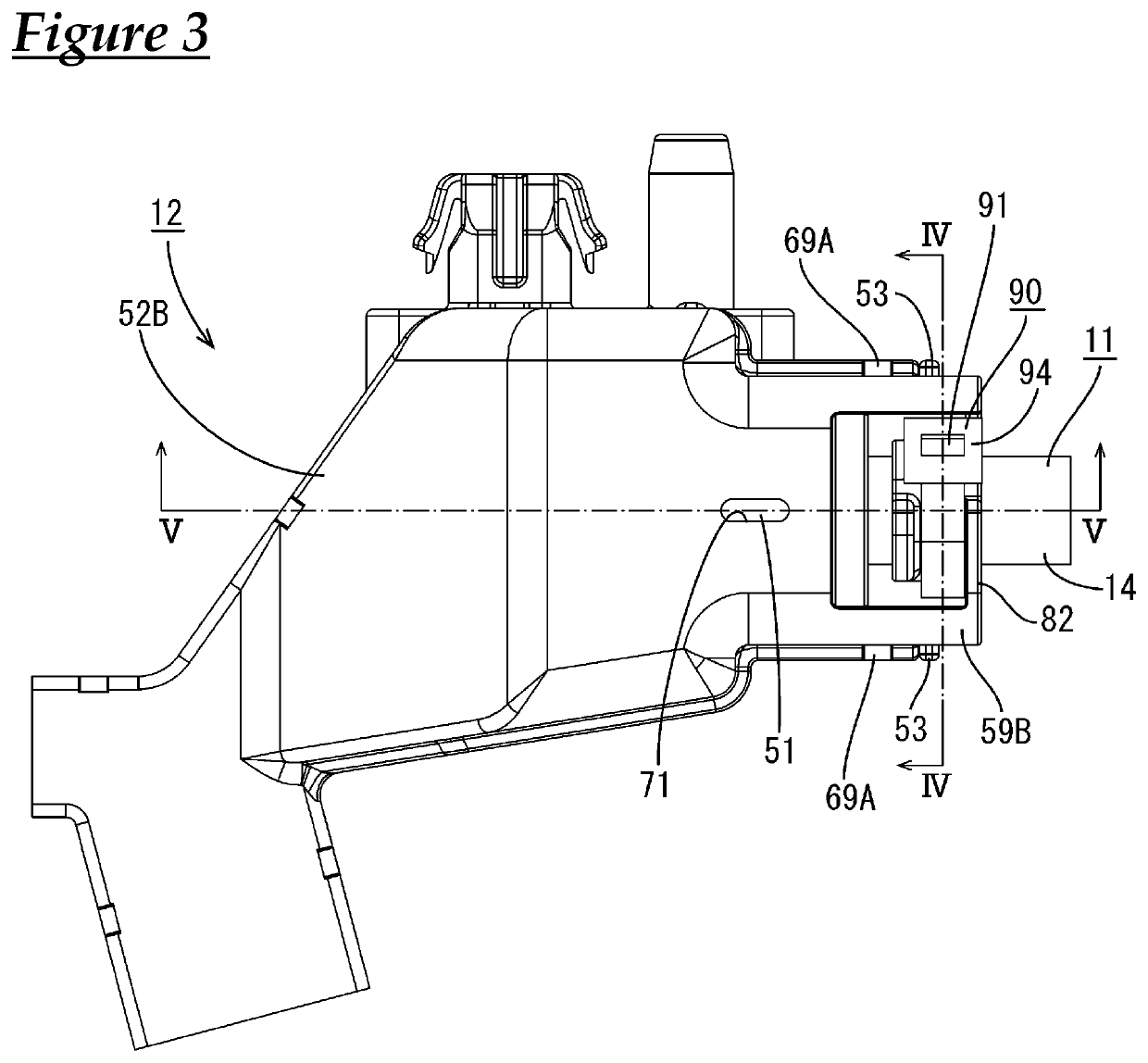

[0032]Embodiment 1 to which the technology disclosed in this specification is applied to a holding structure 12 for a cable 11 will be described with reference to FIGS. 1 to 11. The present embodiment can be applied to a wire harness for an electrical parking brake that is installed in a vehicle (not shown), for example. As shown in FIG. 1, the holding structure 12 includes the cable 11 and a holder 52 configured to hold the cable 11. In the following description, “top” refers to the upper side in FIG. 2, and “bottom” refers to the lower side in FIG. 2. Note that the above-described directions are used for convenience of the description, and the holding structure 12 can be disposed in any orientation with respect to the vehicle.

[0033]The rubber plug 15 is fitted around an end portion 14A of the sheath 14 of the cable 11. The cap 17 is fitted around this rubber plug 15. The cable 11 and the cap 17 are held by the holder 52.

[0034]As shown in FIG. 1, the cable 11 according to the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com