Hot-dip al-plated steel sheet production method, and hot-dip al-plated steel sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0065]The following description will discuss an embodiment of the present invention. Note that (i) a hot-dip Al-based metal-plated steel sheet in accordance with an embodiment of the present invention and (ii) a method for producing the hot-dip Al-based metal-plated steel sheet have configurations similar to the configurations of the comparative example (described earlier) unless otherwise stated. Note that, unless otherwise specified, the present invention is not limited to the following description, which is provided so that subject matters of the present invention are better understood. Note also that a numerical expression such as “A to B” as used herein means “not less than A and not more than B”.

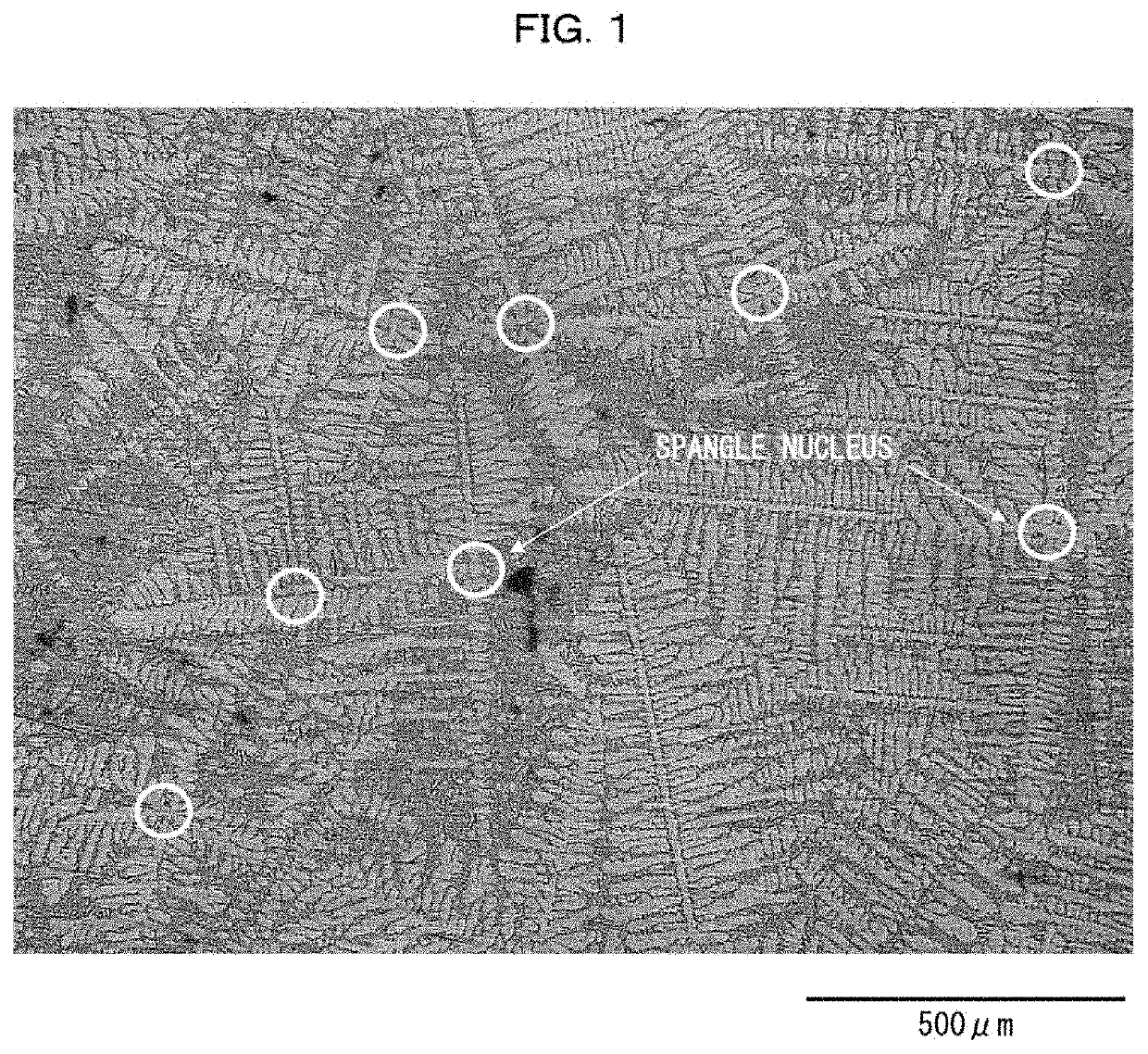

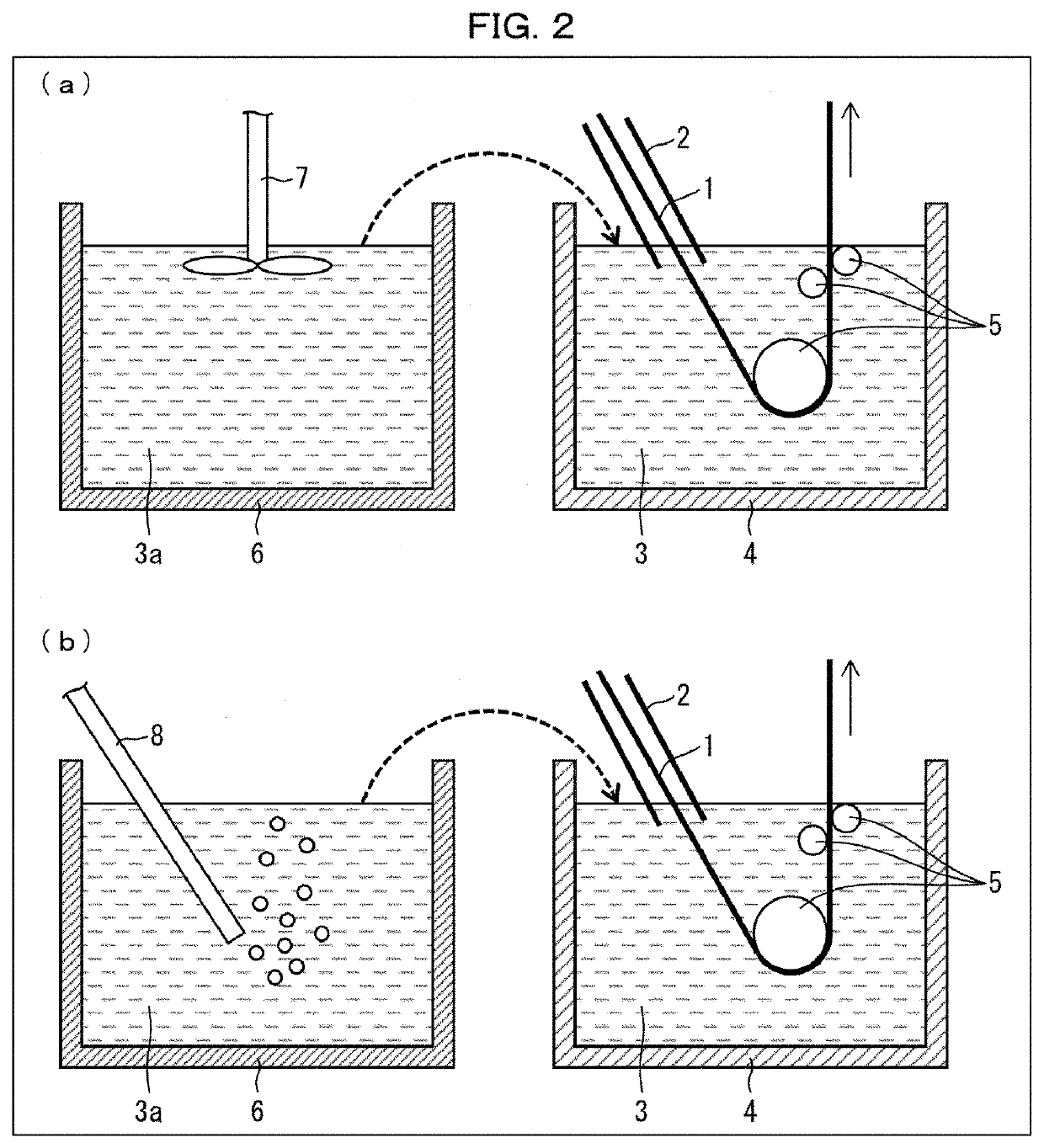

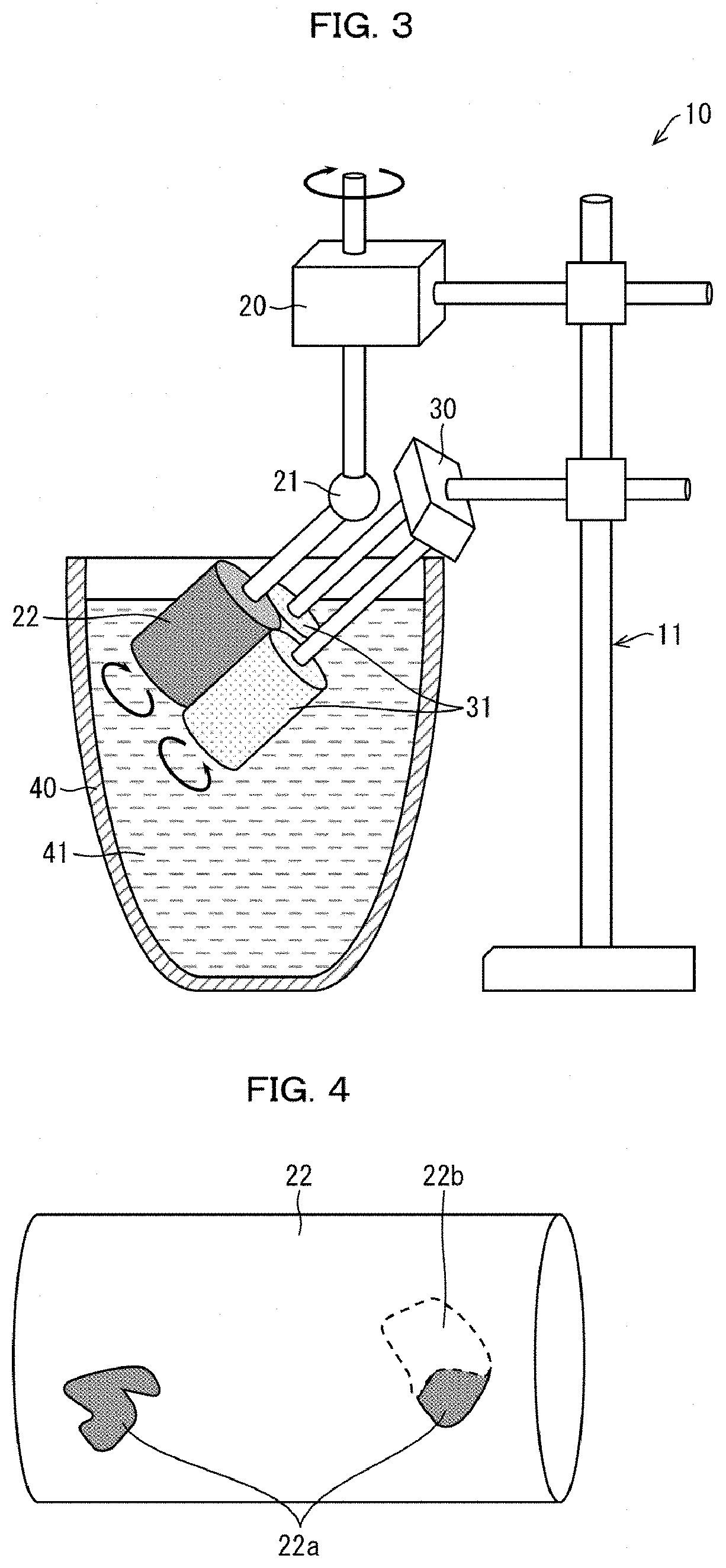

[0066]The following description will schematically discuss knowledge of the present invention before discussing (i) a hot-dip Al-based metal-plated steel sheet in accordance with an embodiment of the present invention and (ii) a method for producing the hot-dip Al-based metal-plated st...

example 1

[0120]An Al-20 mass % Si master alloy was used to adjust an Si concentration in an aluminum plating bath to 9 mass %. Then, an Al-4 mass % B master alloy was added, in a predetermined amount, to the aluminum plating bath so that a B concentration in the aluminum plating bath was adjusted to 0% to 1%. Table 1 shows a result obtained by carrying out a chemical analysis with respect to a composition of the Al-4 mass % B master alloy added. Each figure shown in Table 1 indicates mass %.

TABLE 1Chemical composition (mass %)BSiFeK4.20.130.160.20

[0121]Assuming that Fe coming from, for example, a substrate steel sheet and a member of a pot would be unavoidably mixed in the aluminum plating bath during continuous production, cast iron that was made of a material of which the pot was made was melted so that an Fe concentration in the aluminum plating bath was adjusted to 2.0 mass %.

[0122]By thus adjusting the composition, Al-based hot-dip plating baths indicated by plating bath Nos. 1 to 10 sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com