Stretch-reducing mill having improved diameter tolerance and wall thickness tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]Preferred exemplary embodiments are described below with reference to the Figures. Identical, similar or identically functioning elements are provided with identical reference symbols in the Figures, and a repetitive description of these elements is partially dispensed with in order to avoid redundancies.

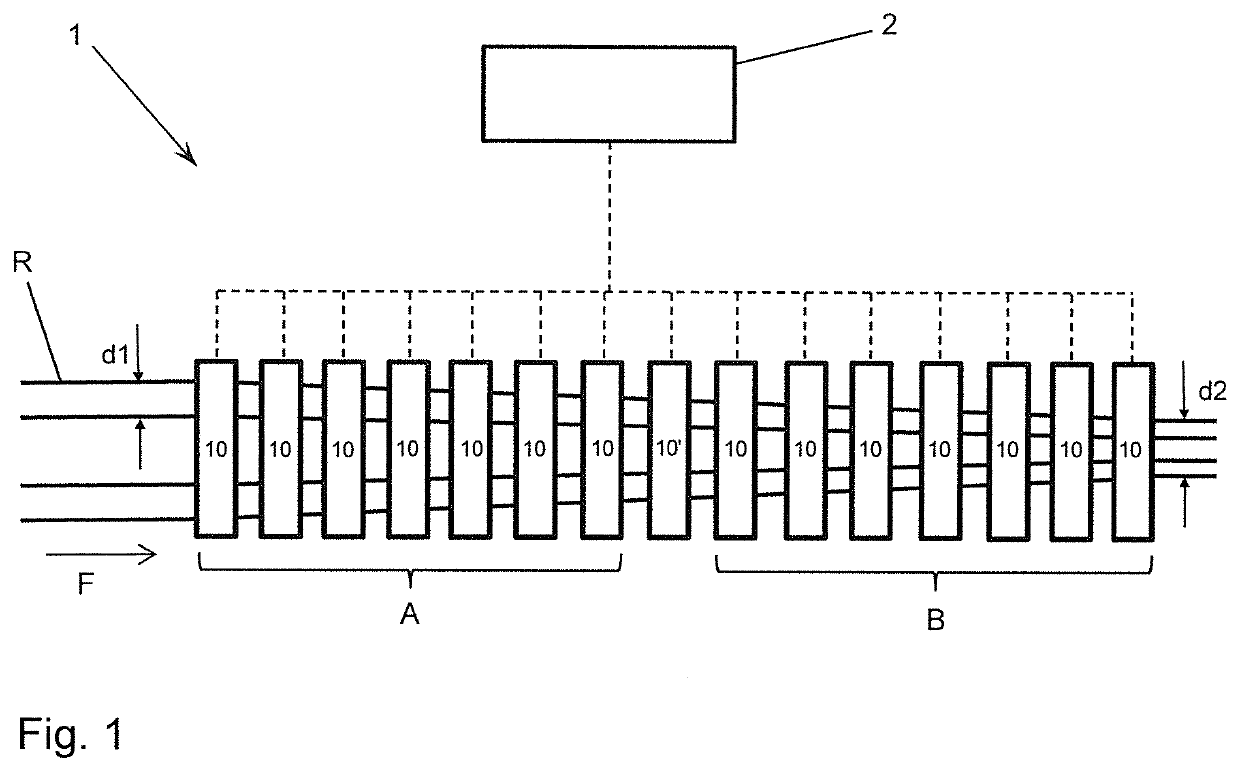

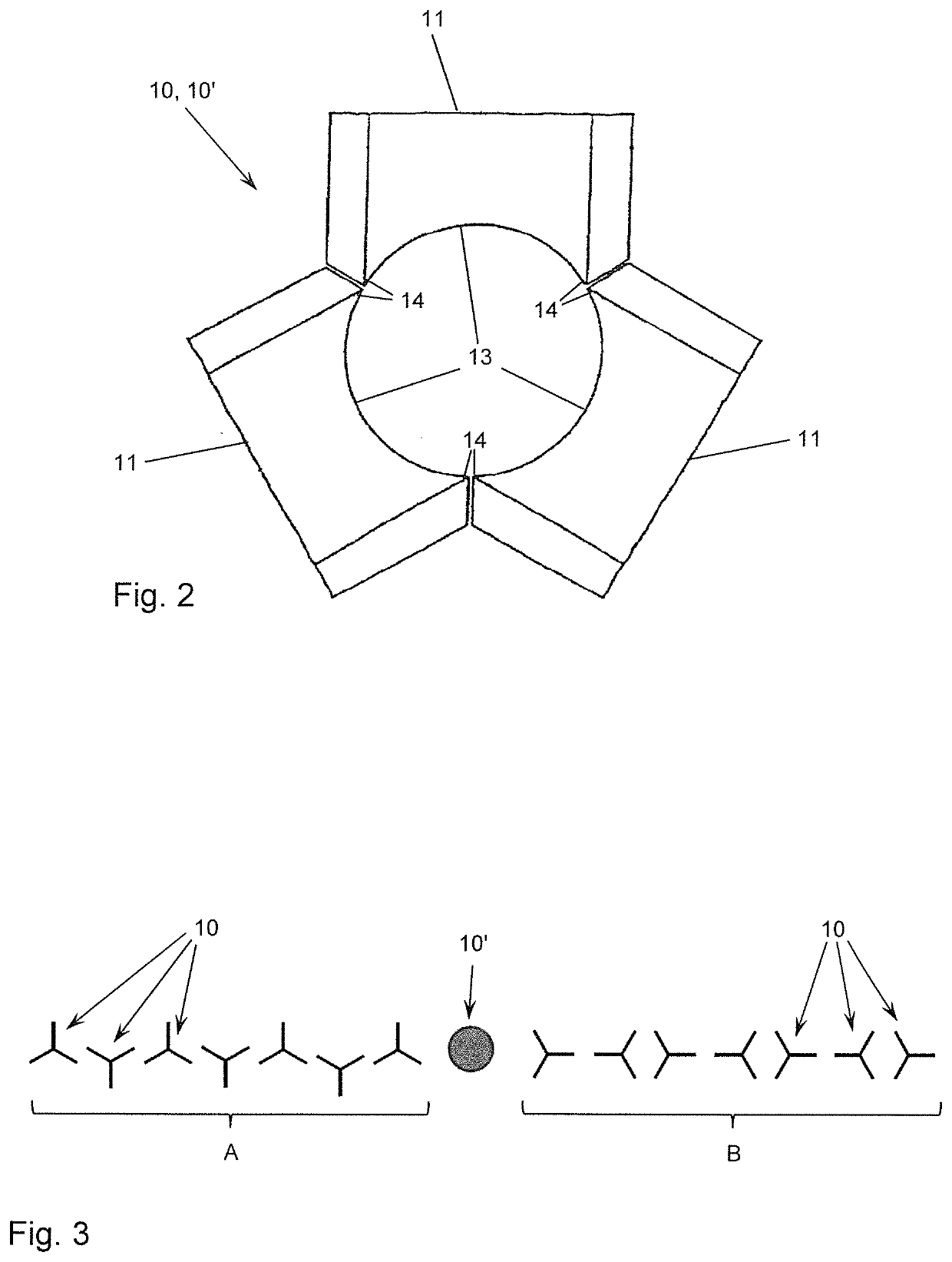

[0023]FIG. 1 is a schematic view of a stretch-reducing mill 1. The stretch-reducing mill 1 has a plurality, here fifteen, roll stands 10. The roll stands 10 can preferably be controlled individually. In particular, the speeds of the rolls 11 (see FIG. 2) of the roll stands 10 can be set individually.

[0024]The rolling stands 10 are controlled via a control device 2, preferably computer-based. The control device 2 takes over the control of further components of the stretch-reducing mill 1 if necessary. It should be pointed out that the term “control device” includes both centralized and decentralized structures for controlling the stretch-reducing mill 1. The control device 2 th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com