Centrifugal pump for conveying a fluid

a centrifugal pump and fluid technology, applied in the direction of non-positive displacement fluid engines, radial flow pumps, non-positive displacement pumps, etc., can solve the problems of reducing the hydraulic performance or reducing etc., to achieve the highest possible power ratio, reduce the efficiency of the pump, and increase the awareness of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

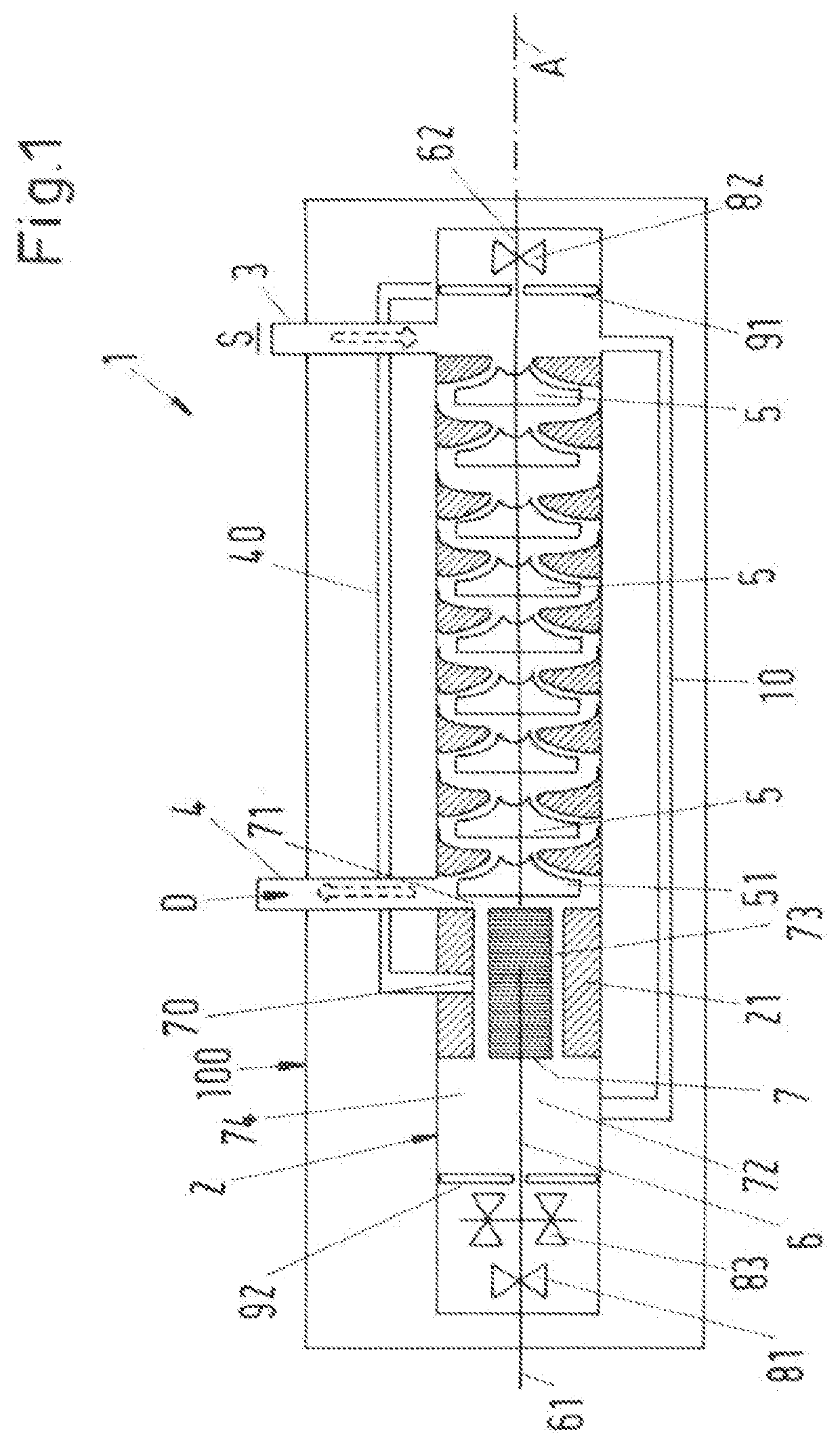

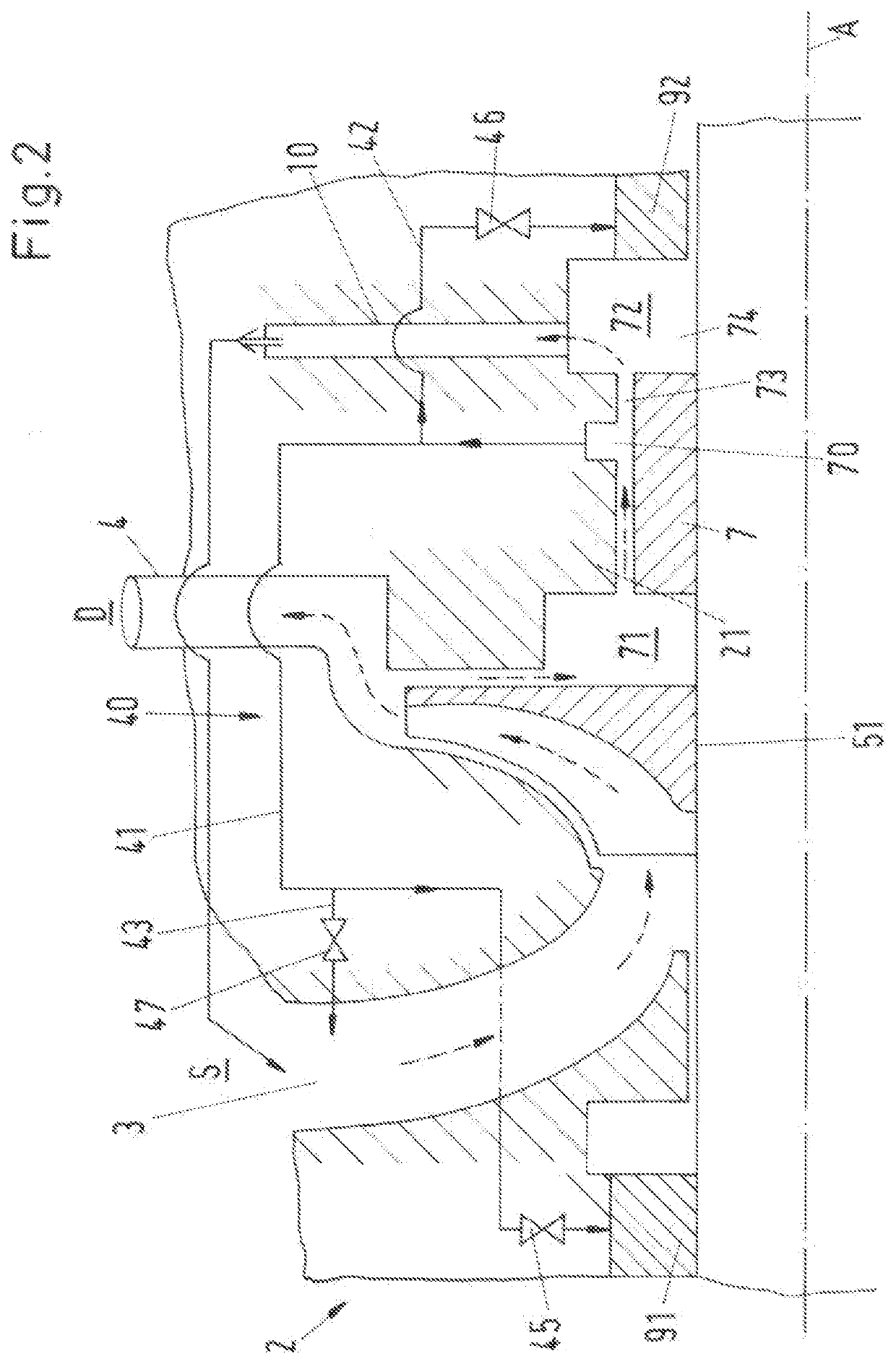

[0031]FIG. 1 shows a schematic cross-sectional view of an embodiment of a centrifugal pump according to the invention, which is designated in its entity with reference numeral 1. The pump 1 is designed as a centrifugal pump for conveying a fluid, for example a liquid such as water.

[0032]The centrifugal pump 1 comprises a pump housing 2 having an inlet 3 and an outlet 4 for the fluid to be conveyed. The inlet 3 is arranged at a suction side S, where a suction pressure prevails, and the outlet 4 is arranged at a discharge side D, where a discharge pressure prevails. The suction pressure is also referred to as low pressure, and the discharge pressure is also referred to as high pressure. The centrifugal pump 1 further comprises at least one impeller 5, 51 for conveying the fluid from the inlet 3 to the outlet 4 as indicated by the dashed arrows without reference numerals, as well as a shaft 6 for rotating each impeller 5, 51 about an axial direction A. The axial direction A is defined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com