Computer aided contact lens design and fabrication using spline surfaces

a technology of contact lens and computer aided design, applied in the field of computer aided contact lens design and fabrication using spline surfaces, can solve the problems of unnecessarily large representation, inefficient, and inability to address the determination of the optics of the lens by Ducharme, so as to improve the fit, improve the effect of optics, and improve the fi

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

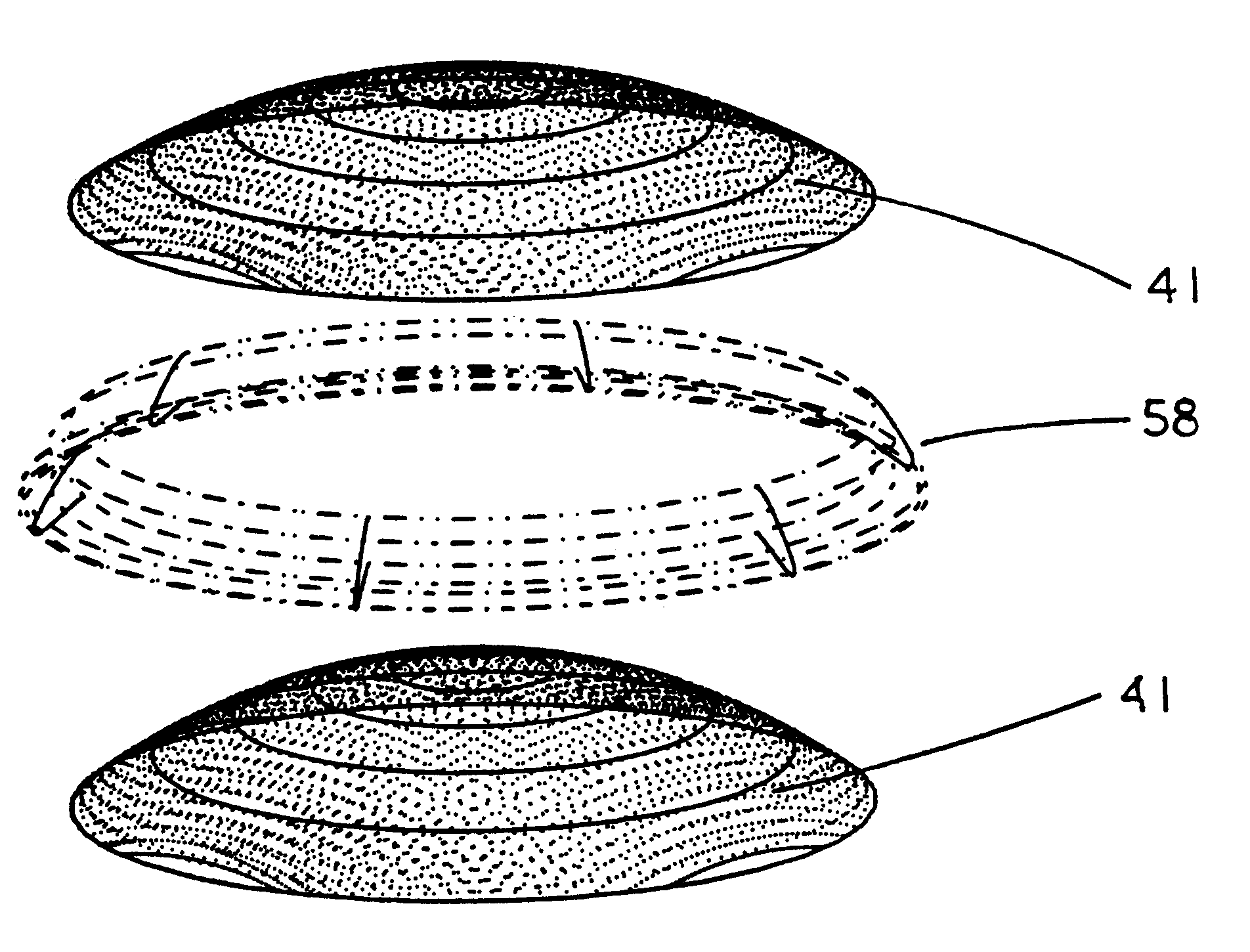

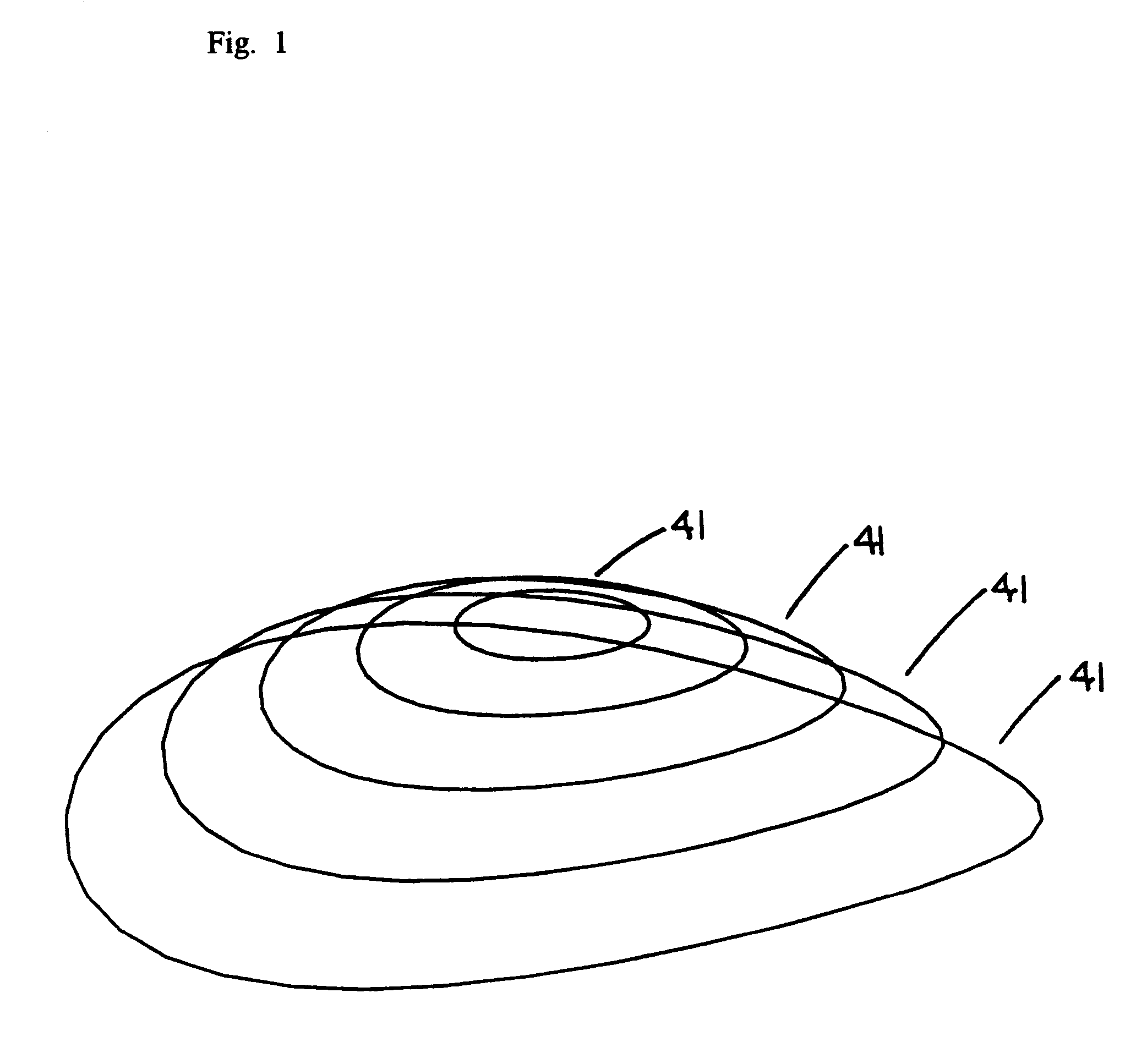

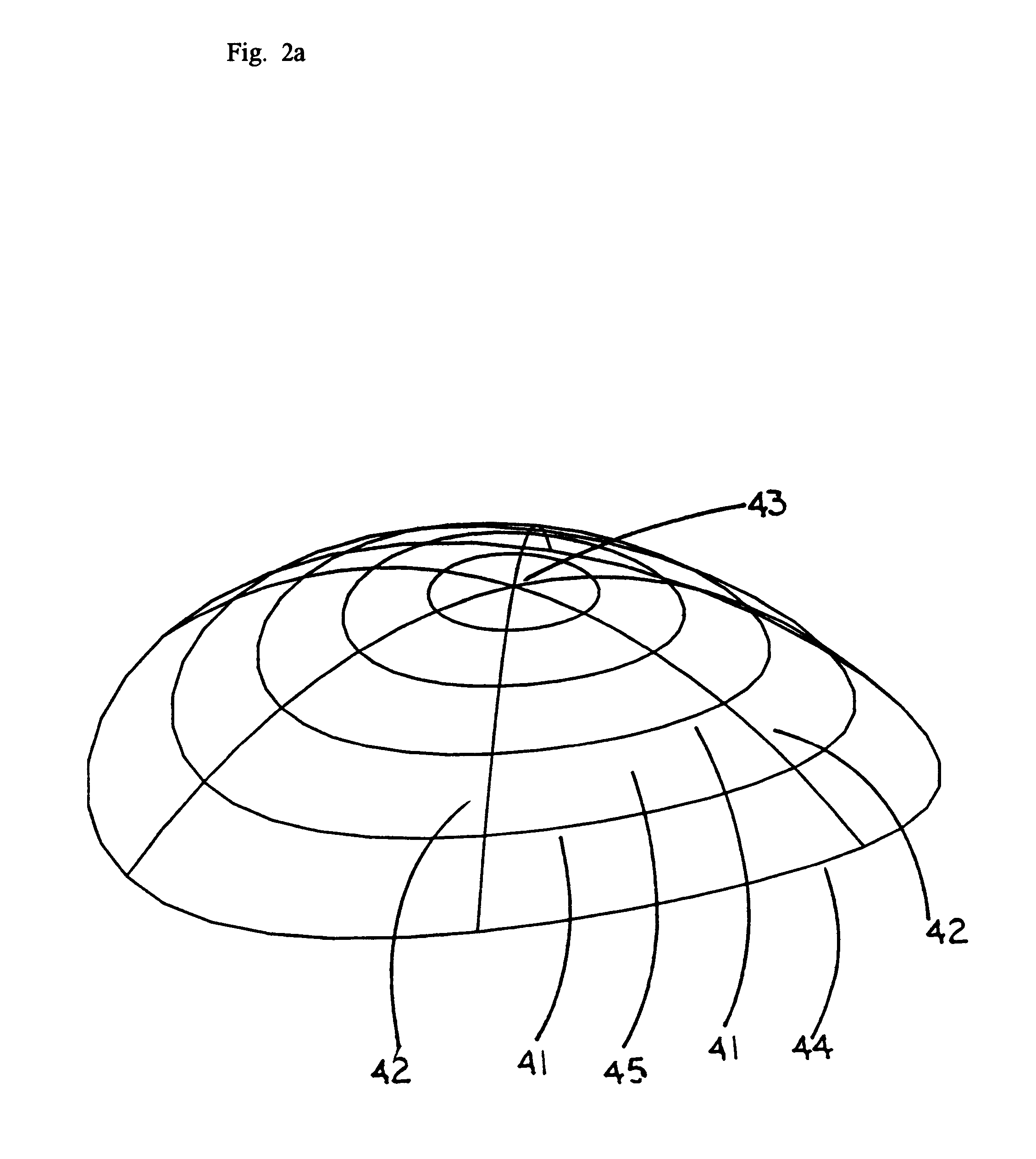

A primary application of spline-based contact lens design is the creation of contact lenses for keratoconus. These lenses need complex posterior surface shapes to accommodate the "cone". As an example, but without limitation, FIG. 21 shows such a keratoconus lens using spline-based mathematical geometry to describe the anterior surface 56, posterior surface 57, and peripheral edge system (PES) 58. The posterior surface has a local region of much higher curvature than the overall surface (minimum radius of curvature of 4.5 mm compared to overall radius of curvature of 7.67 mm) and yet the surface is smooth and the curvature continuously varies across the surface. In FIG. 21a, the surfaces are decomposed into pieces corresponding to FIGS. 2b and 11b, that is, a sequence of annular regions, which are further subdivided by adding a set of radial lines 42, emanating from a given annular border 41 and terminating at the periphery 44, thereby forming a collection of four-sided regions 45, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com