Method and apparatus for depalletizing commodities

a technology of commodities and methods, applied in the direction of de-stacking articles, thin material processing, article separation, etc., can solve the problems of huge output loss and enormous output loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

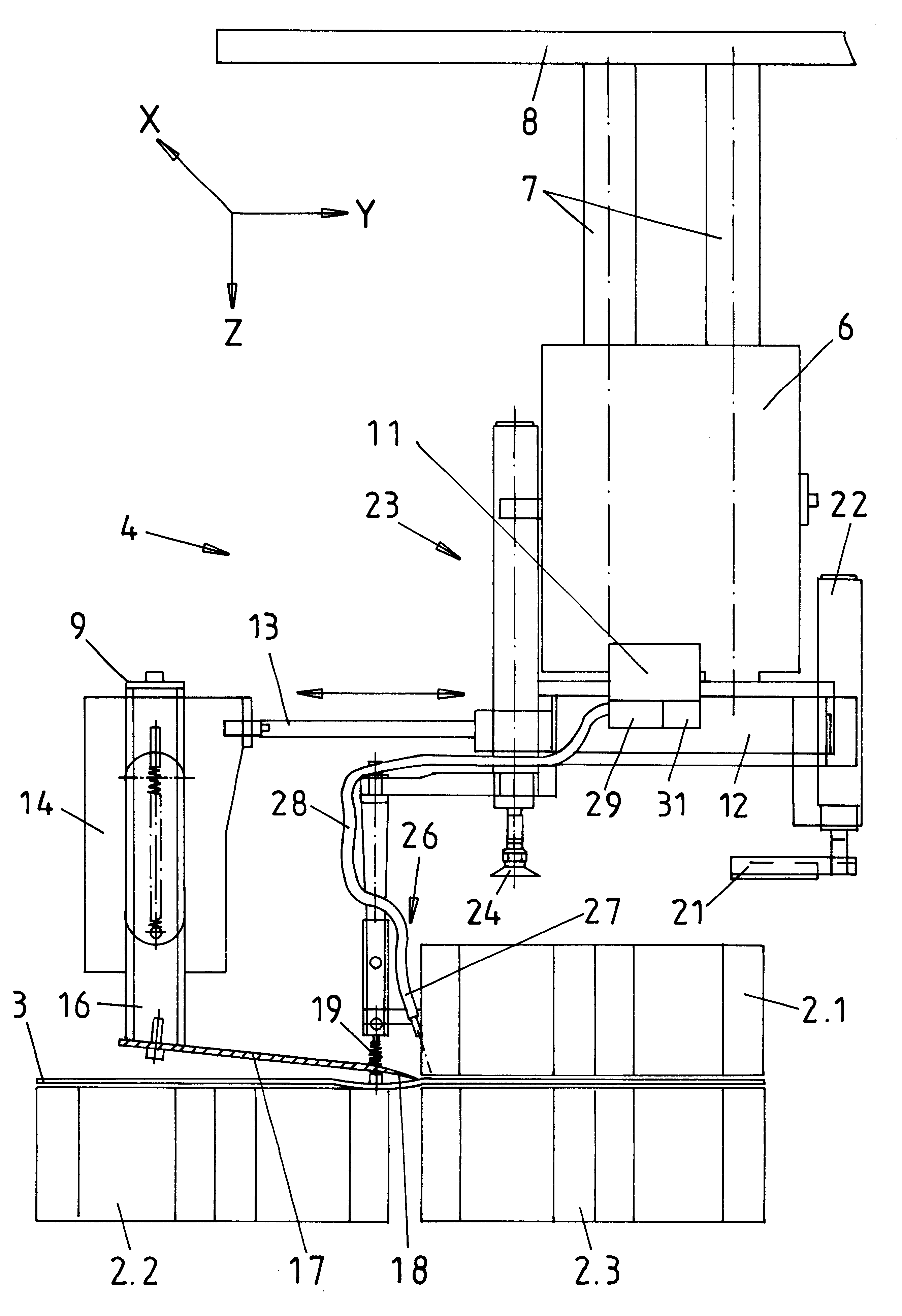

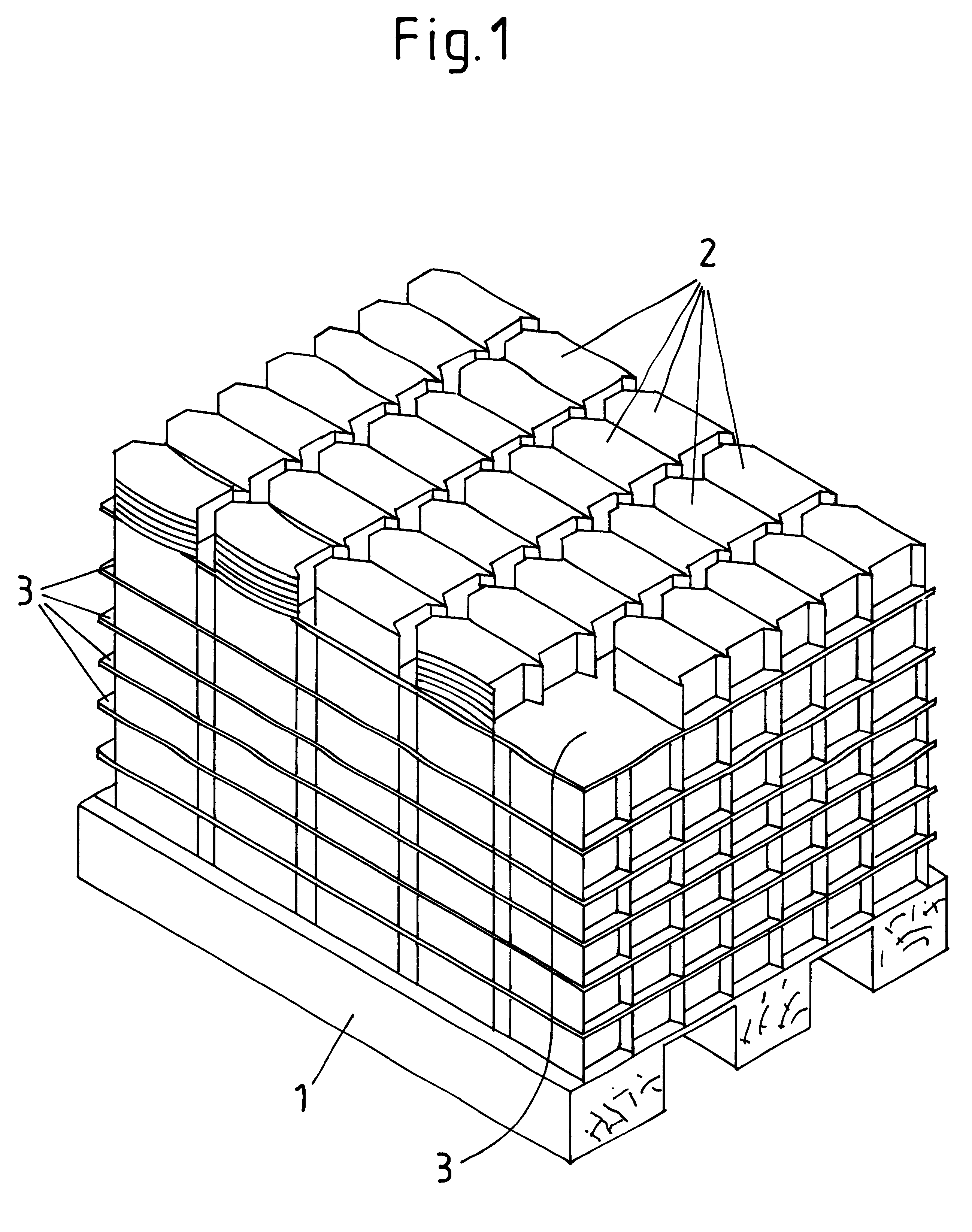

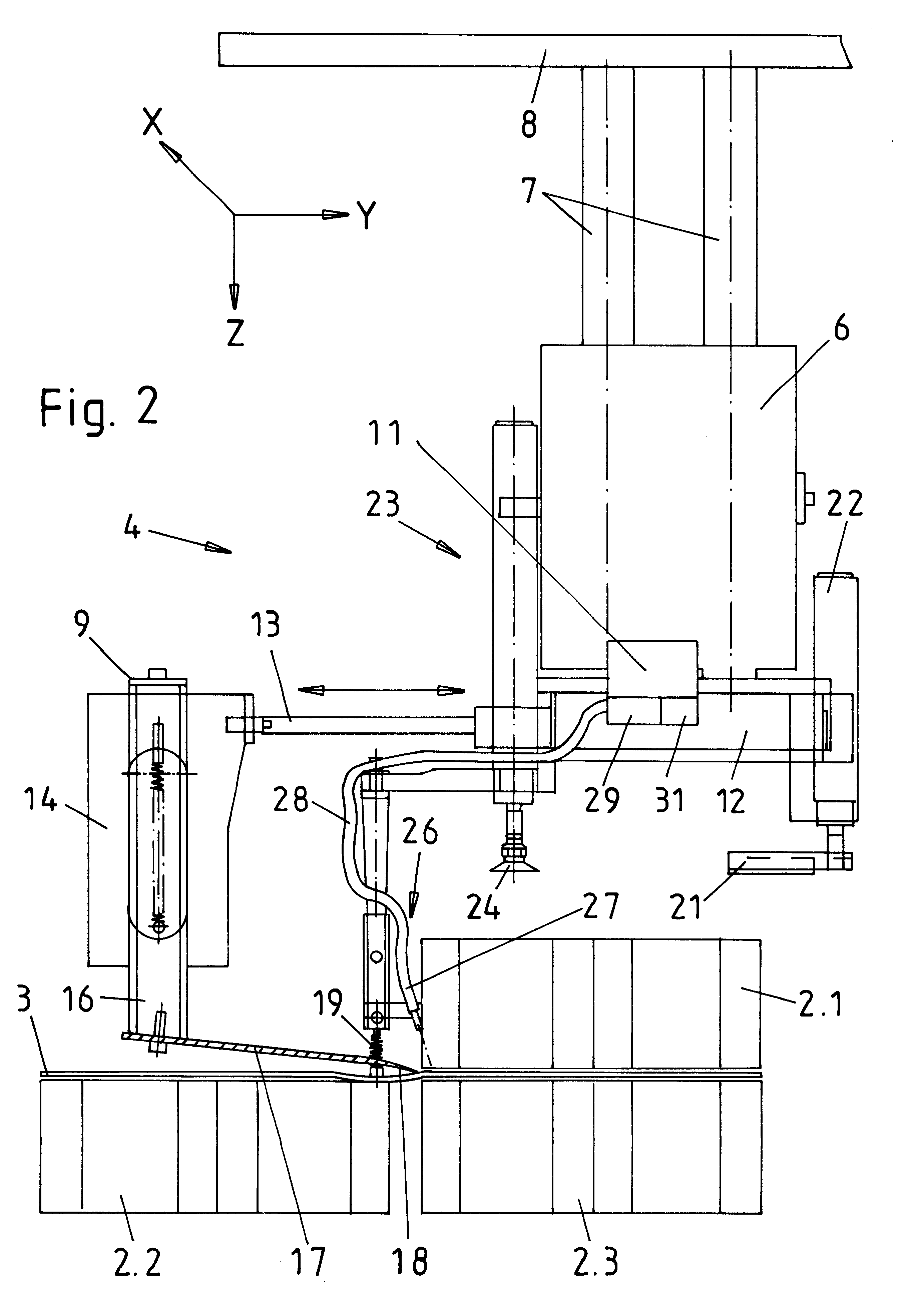

FIG. 1 shows a standard pallet 1 which carries an array of block-shaped commodities 2, e.g., stacks of superimposed at least substantially flat blanks of paper, cardboard and / or other suitable material. The blanks can be designed for conversion into packets for plain or filter cigarettes if the pallet 1 is utilized in a production line to temporarily store commodities 2 (hereinafter called stacks for short) which are to be transferred into the magazine(s) of one or more packing machines for rod-shaped articles of the tobacco processing industry. However, it is to be understood that the method and apparatus of the present invention can be utilized for the manipulation (depalletizing) of other types of commodities in machines or production lines which may but need not necessarily be utilized in the tobacco processing industry.

The stacks 2 are arranged in several horizontal layers, and each such layer rests on a sheet- or panel-like support 3, e.g., a support made of cardboard or the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com