Surface lighting device with closed oblique reflector

a surface lighting and reflector technology, applied in lighting and heating equipment, instruments, mechanical equipment, etc., can solve the problems of increasing costs, increasing costs, and affecting the uniformity of surface lighting devices, so as to improve the utilization of light beams and enhance uniform illumination and brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

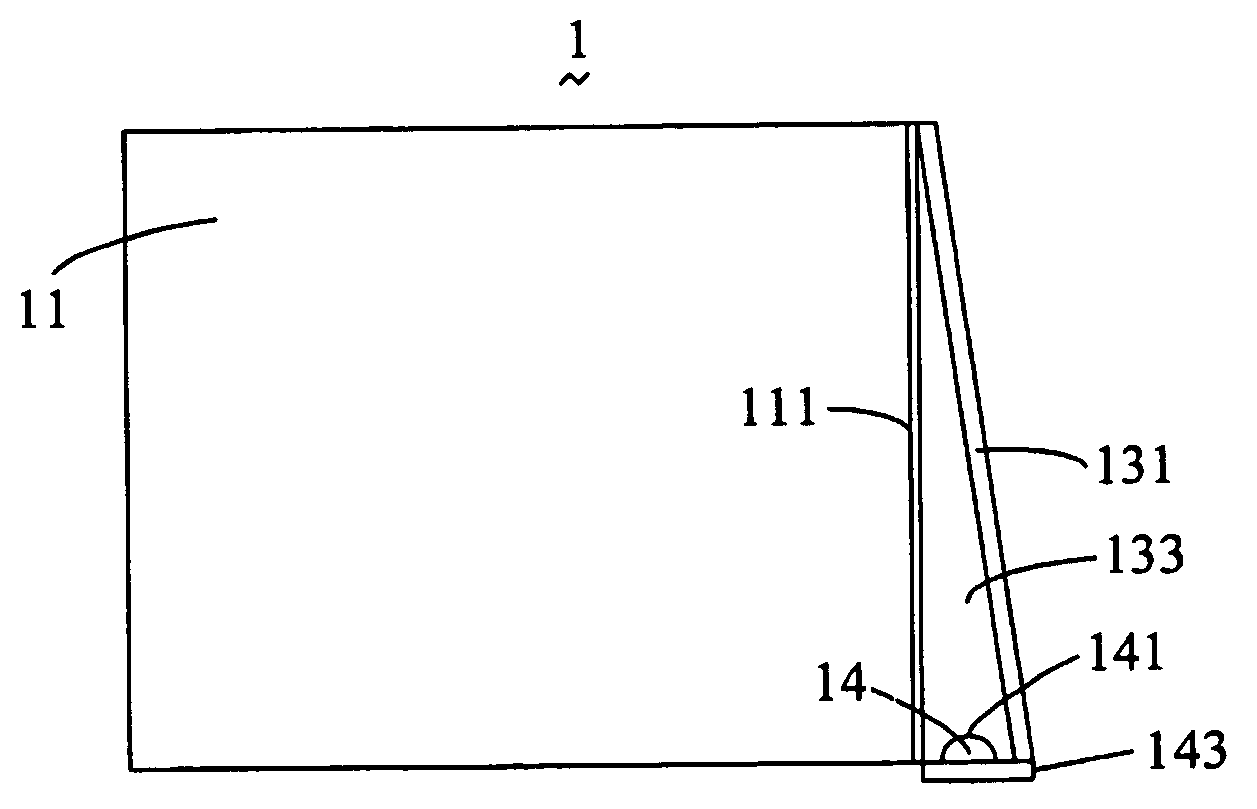

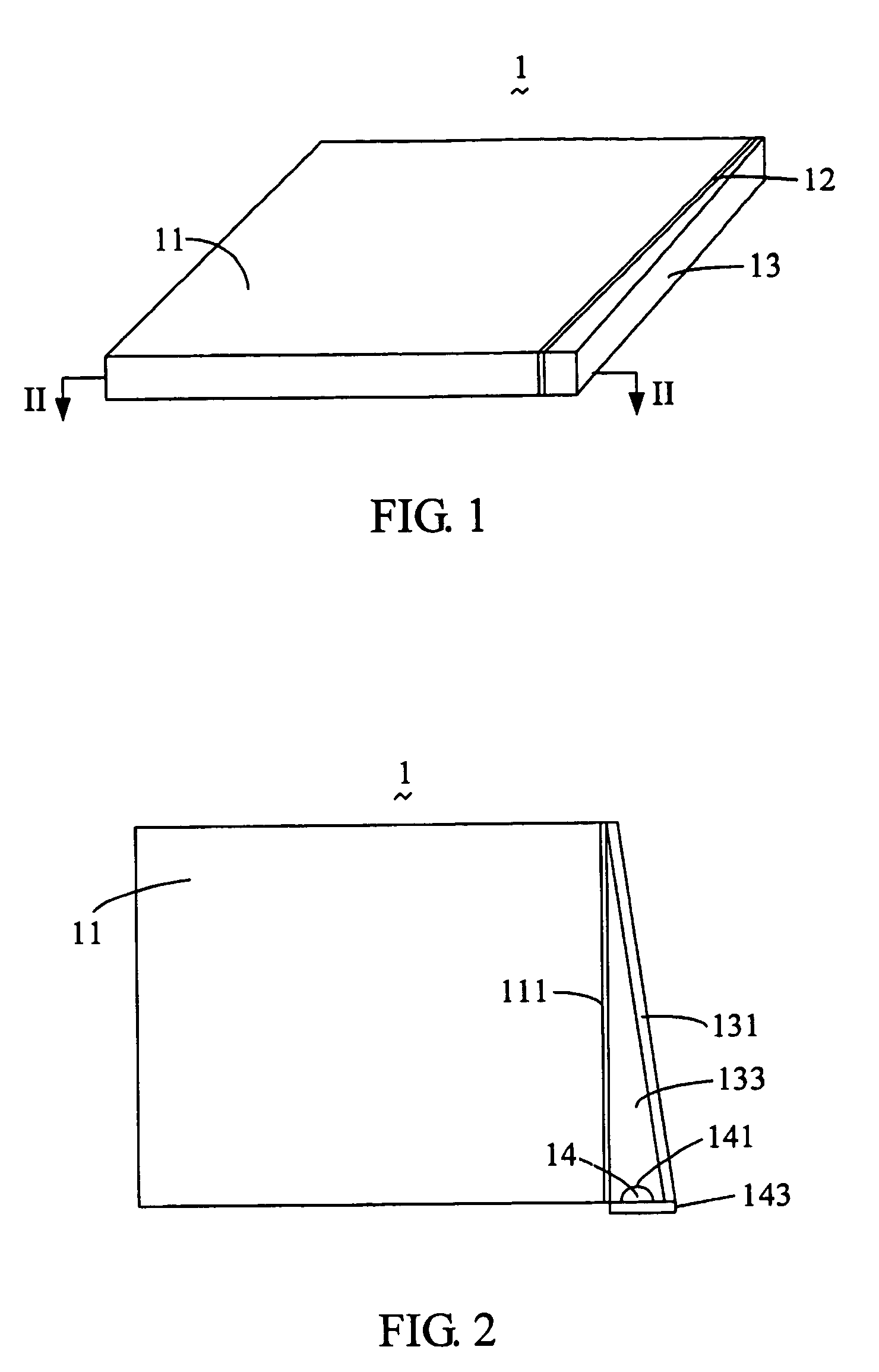

[0019]Referring to FIGS. 1–2, a first surface lighting device 1 in accordance with the present invention is used to illuminate a liquid crystal display panel. The surface lighting device 1 comprises a light guide plate 11, a brightness enhancement film 12, a light reflector 13, and an LED 14 for providing light beams.

[0020]The light guide plate 11 is a rectangular slab of transparent material such as acrylic resin, polycarbonate resin, polyvinyl chloride, or glass. The light guide plate 11 comprises a light incident surface 111, a light output surface (not labeled) adjoining the light incident surface 111, and a bottom surface (not labeled) opposite to the light output surface. The light output surface and / or the bottom surface of the light guide plate 11 can be formed with a dot-pattern of light diffusers (not shown) or with V-cut grooves (not shown), for scattering incident light and improving a brightness and uniformity of the light guide plate 11.

[0021]The brightness enhancement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com