Directional microphone

a directional microphone and microphone technology, applied in the direction of frequency/directions obtaining arrangements, transducer types, electrical equipment, etc., can solve the problems of very high demands on the amplitude and phase compensation of the microphone, and the arrangement has a clearly reduced directional effect, so as to achieve good directional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

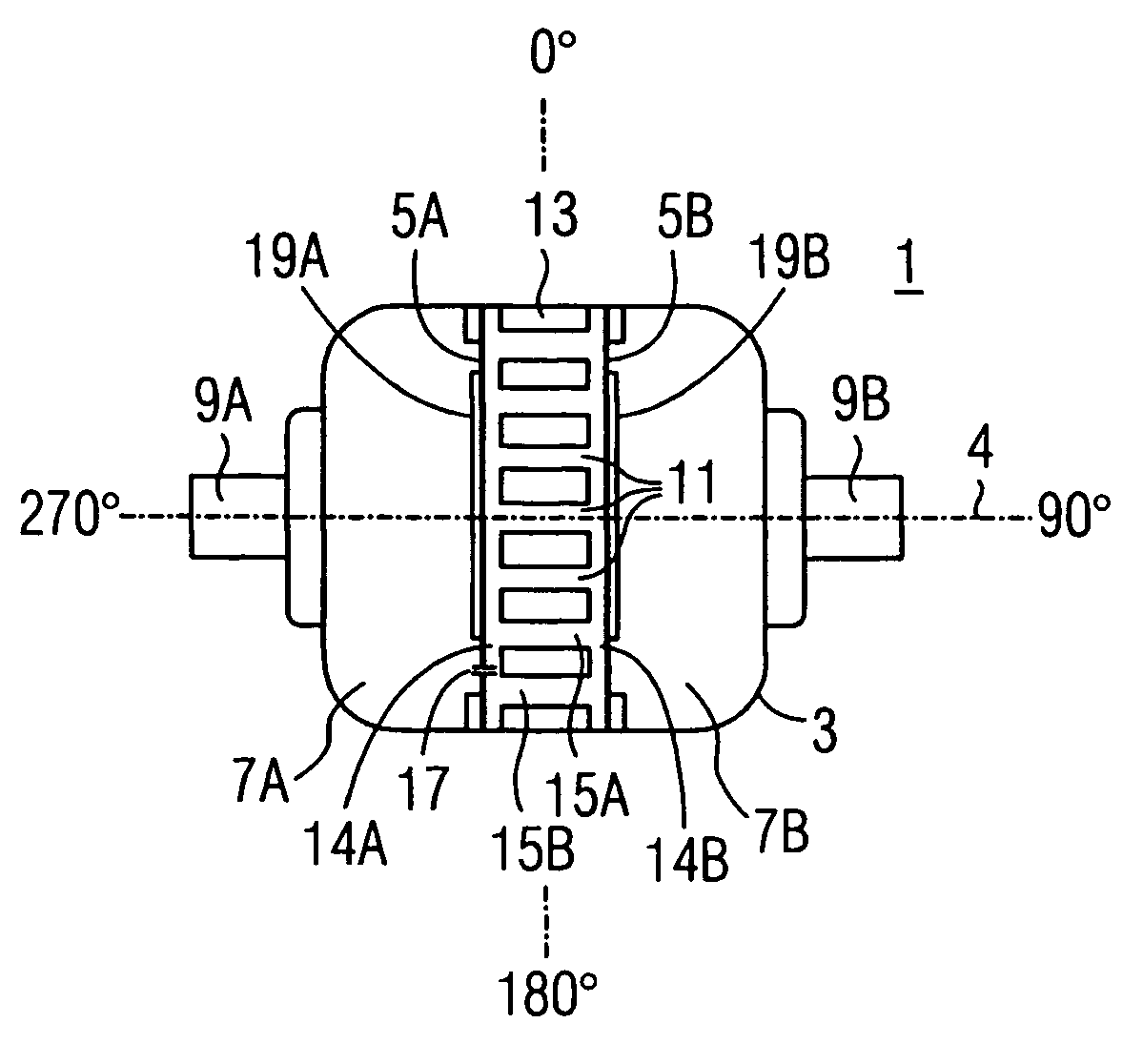

[0023]FIG. 1 shows a schematic assembly of an embodiment of a directional microphone 1 with a cylindrically formed housing 3 in the section along the cylinder axis 4. Located in the housing 3 are two membranes 5A, 5B, preferably arranged perpendicular to the cylinder axis 4, that are preferably attached air-tight to the housing 3 via mountings. The membranes 5A, 5B are in contact with air volumes 7A, 7B. If a sound wave impinges on the sound entrance ports 9A, 9B, it arrives in the air volumes 7A, 7B and effects an oscillation (vibration) of the membranes 5A, 5B, due to the pressure changed by the sound wave.

[0024]A third air volume 11 and a backplate electrode 13 are located between the two membranes 5A, 5B. The air volume 11 is comprised of two air gaps 14A, 14B that exist between the backplate electrode 13 and the two membranes 5A, 5B, as well as of air ducts 15A, 15B which infuse the backplate electrode 13. The air ducts 15A, 15B are, for example, round air channels running para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com