Cushion pad structure for a carpet installation tool

a technology for installing tools and cushion pads, which is applied in the direction of floor fabrics, constructions, wire tools, etc., can solve the problems of re-installing the entire carpet, presenting pattern matching problems, and uncoordinated patterns on walls or furnitur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

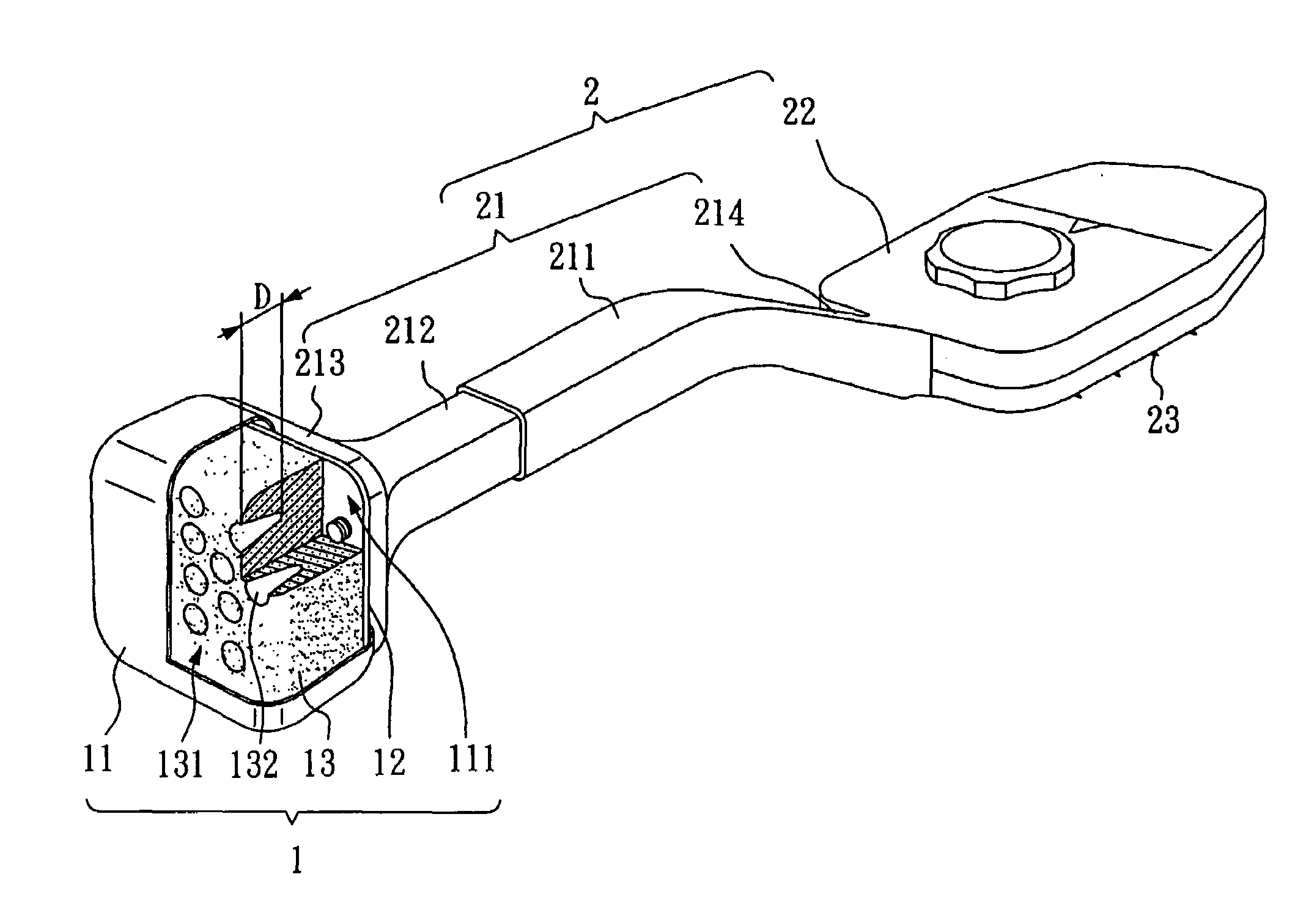

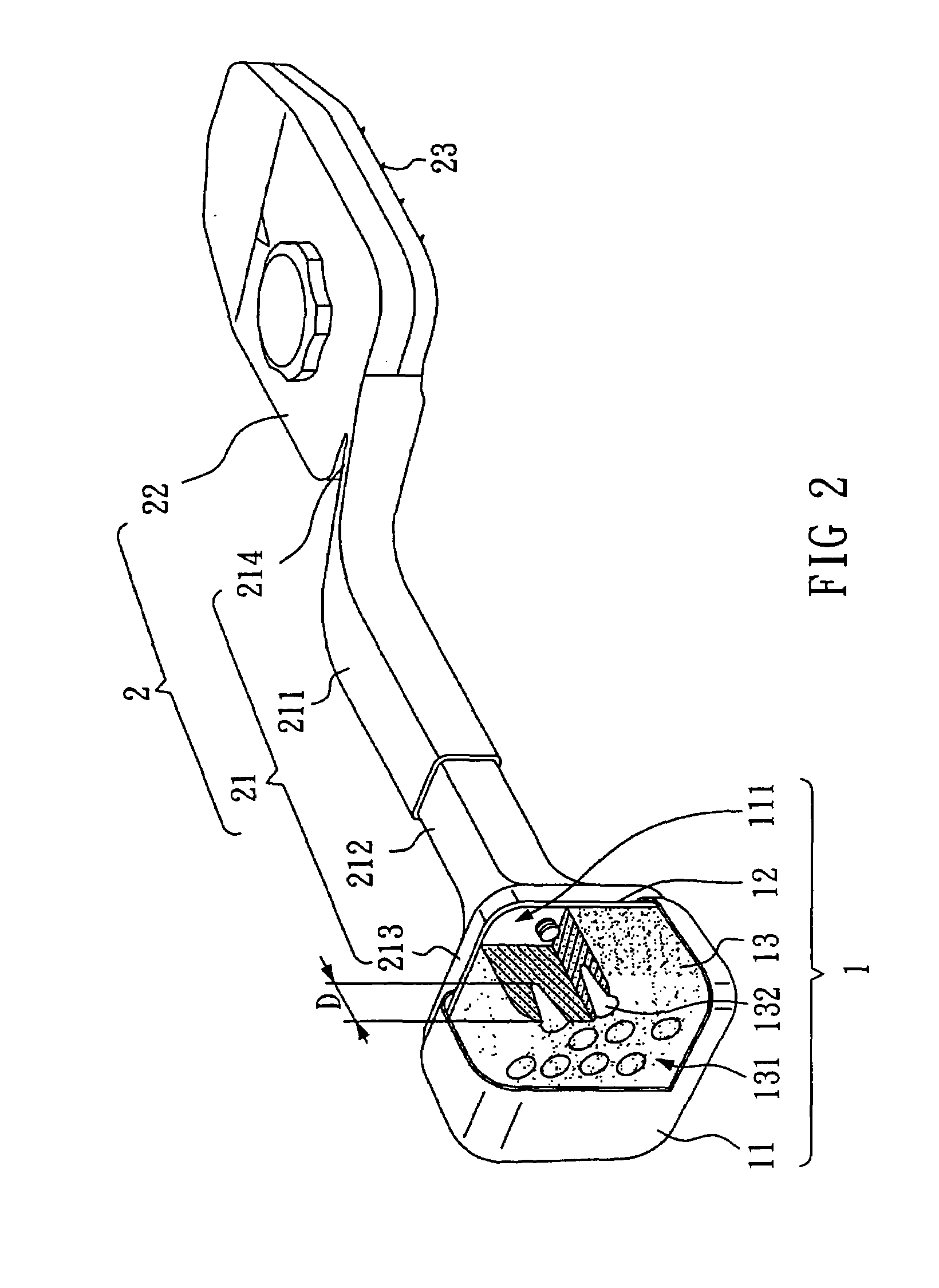

[0029]Please refer to FIG. 2 and FIG. 3. FIG. 2 provides a perspective view of a first embodiment of the present invention. FIG. 3 is a local exploded view of the first embodiment of the present invention. As shown in FIG. 2, a cushion pad 1 of the present invention is mounted at the rear end of a carpet installation tool 2.

[0030]The carpet installation tool 2 comprises a connecting arm 21 and a claw disk 22. As shown in FIG. 2, the connecting arm 21 comprises a front arm 211 and a rear arm 212. One end 214 of the front arm 211 is connected to the claw disk 22, and the claw disk 22 has a plurality of claws 23 extending down and forward (only four claws 23 are shown in the drawing due to the viewing angle). The rear arm 212 is disposed in the front arm 211 so that the length of the connecting arm 21 can be adjusted by the technician. One end 213 of the rear arm 212 is a locking end, which has a cushion pad 1.

[0031]As shown in FIG. 2, the cushion pad 1 comprises a covering layer 11, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com