Sample carrier having sample tube blocking member

a sample carrier and blocker technology, applied in the field of sample carriers, can solve the problems of removing the seal which exerts too great retention force against the fluid transfer device, and achieves the effect of minimizing the chance of contaminating the sample carrier and its contents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054]While the present invention may be embodied in a variety of forms, the following description and accompanying drawings are merely intended to disclose some of those forms as specific examples of the present invention. Accordingly, the present invention is not intended to be limited to the forms or embodiments so described and illustrated. Instead, the full scope of the present invention is set forth in the appended claims.

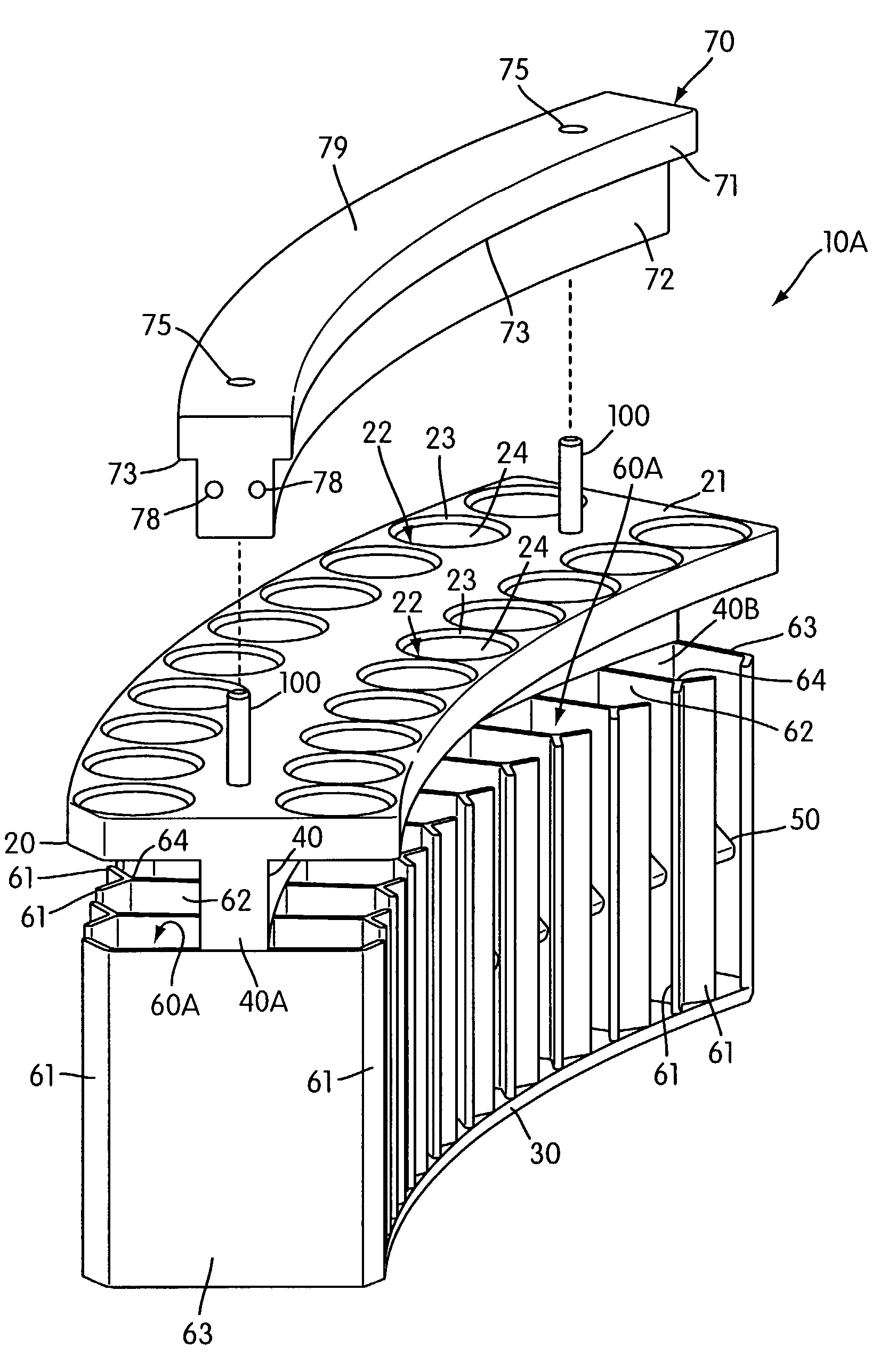

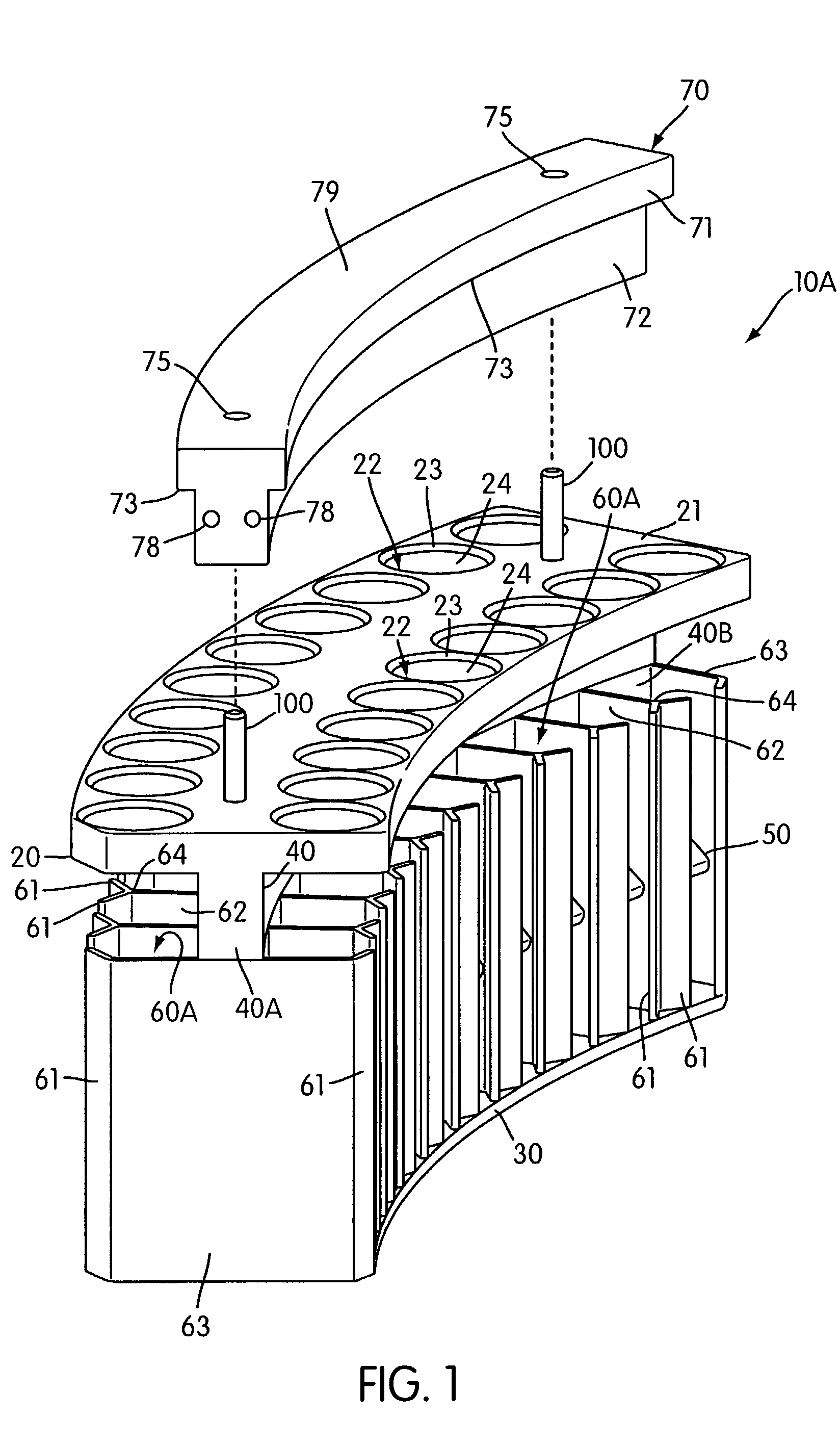

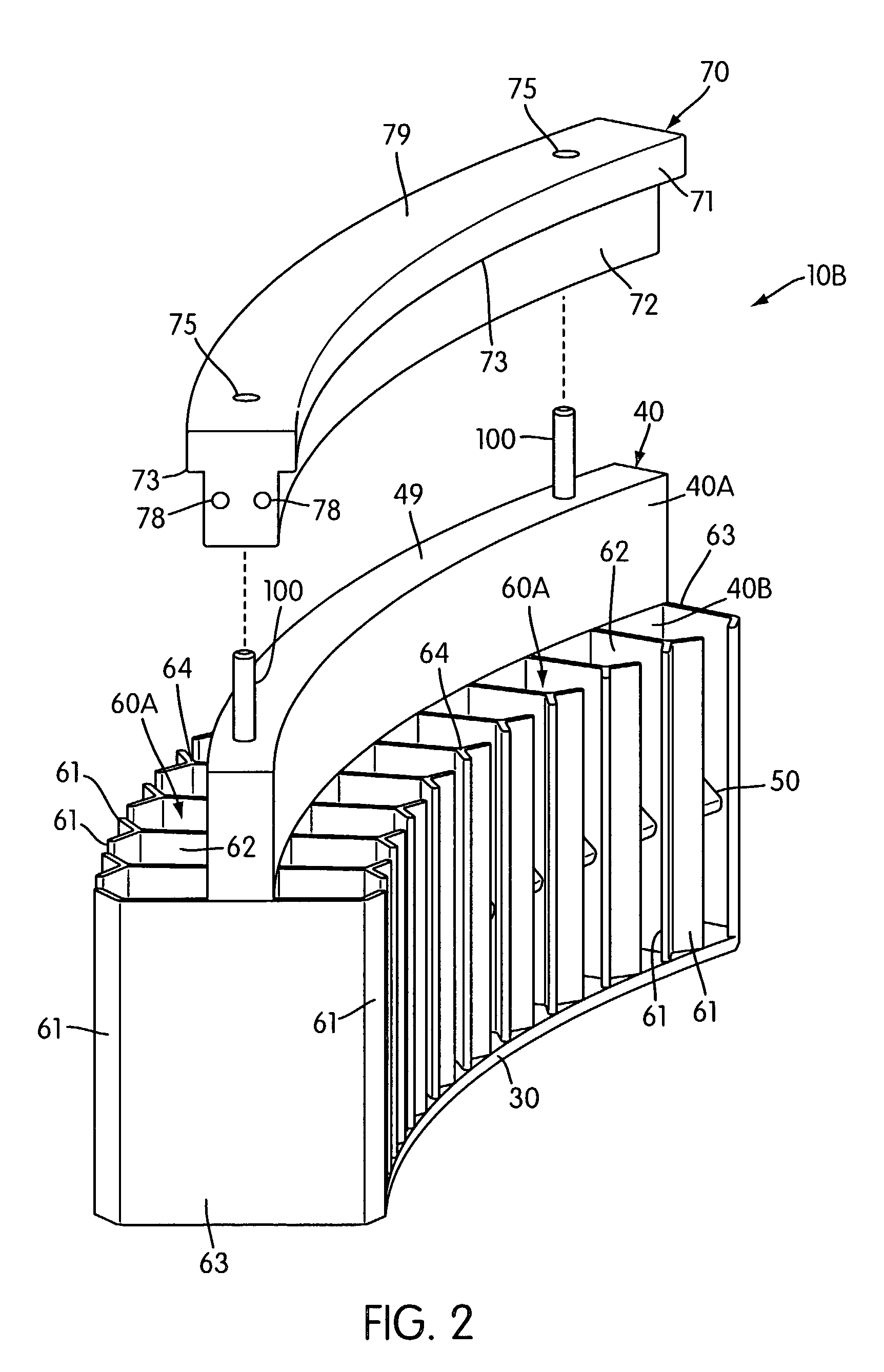

[0055]With reference to the figures, preferred sample carriers 10 of the present invention are shown alone or in combination with a drip shield 200 for protecting against cross-contamination between sample tubes 300 carried by the sample carriers and for limiting vertical movement of the sample carriers when sample is being removed from any of the sample tubes. (Reference herein to a “sample carrier 10” is a general reference of to any of the illustrated sample carriers 10A-D.) Sample carriers 10 of the present invention are preferably used in combination wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com