Asphalt tamper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

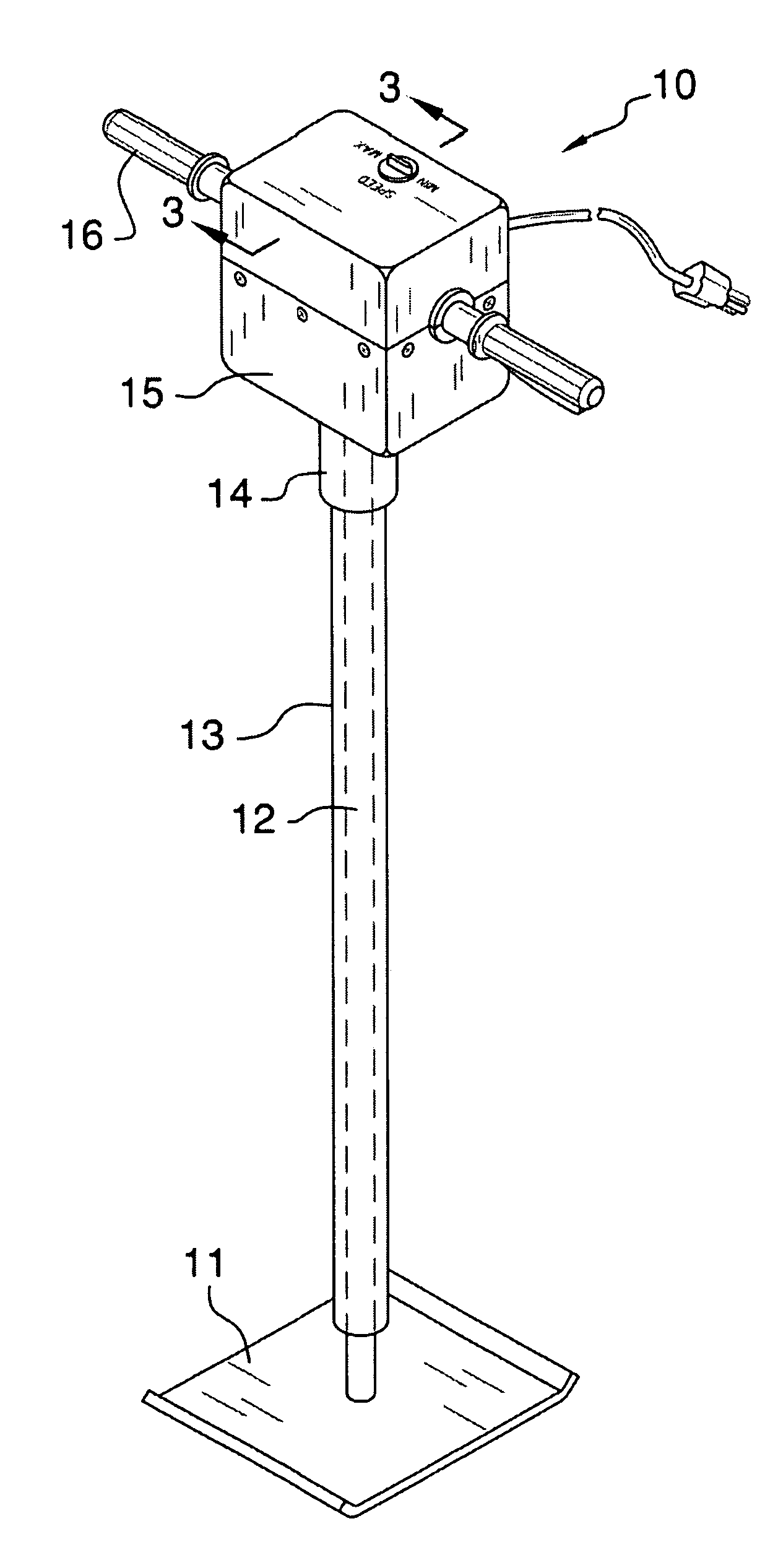

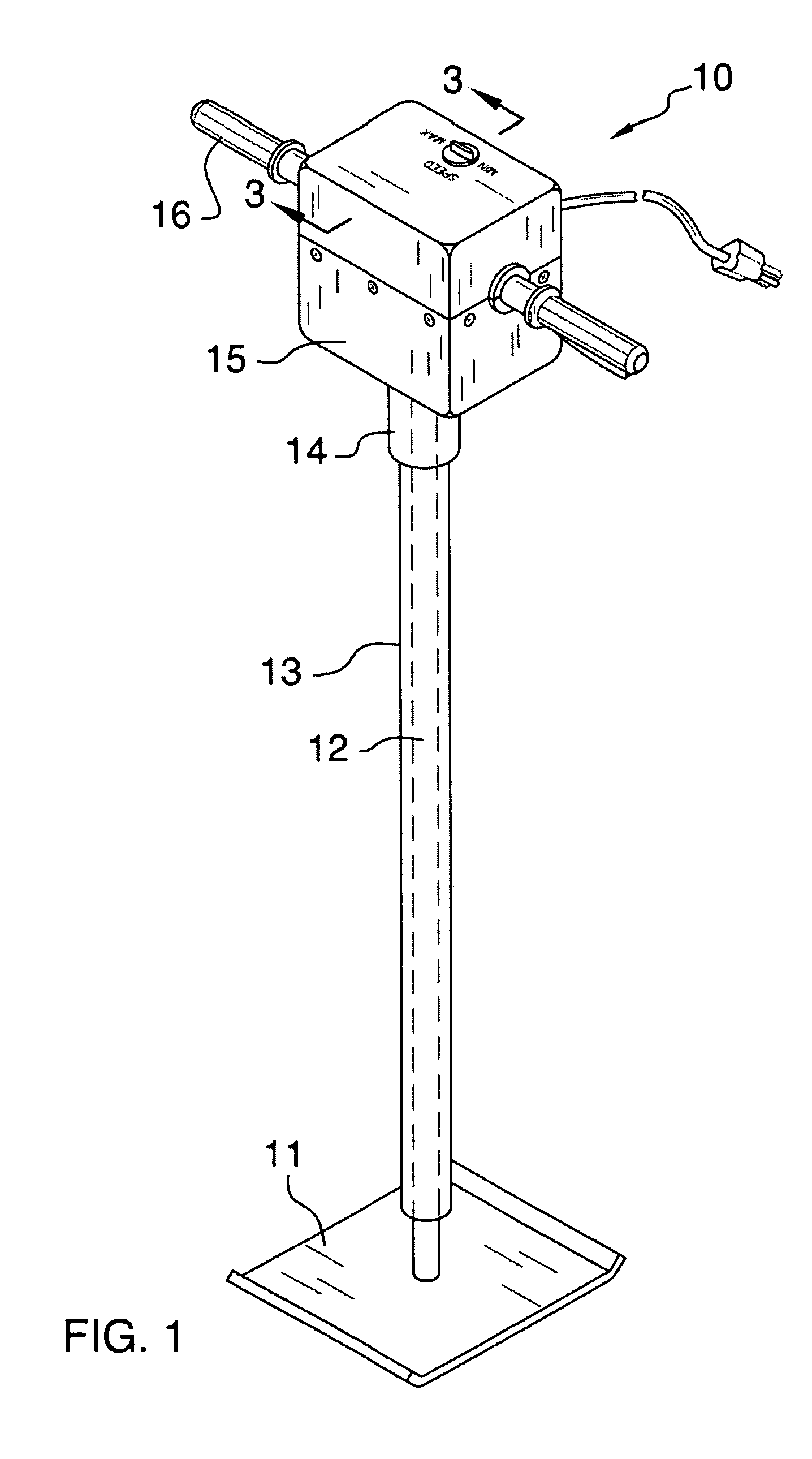

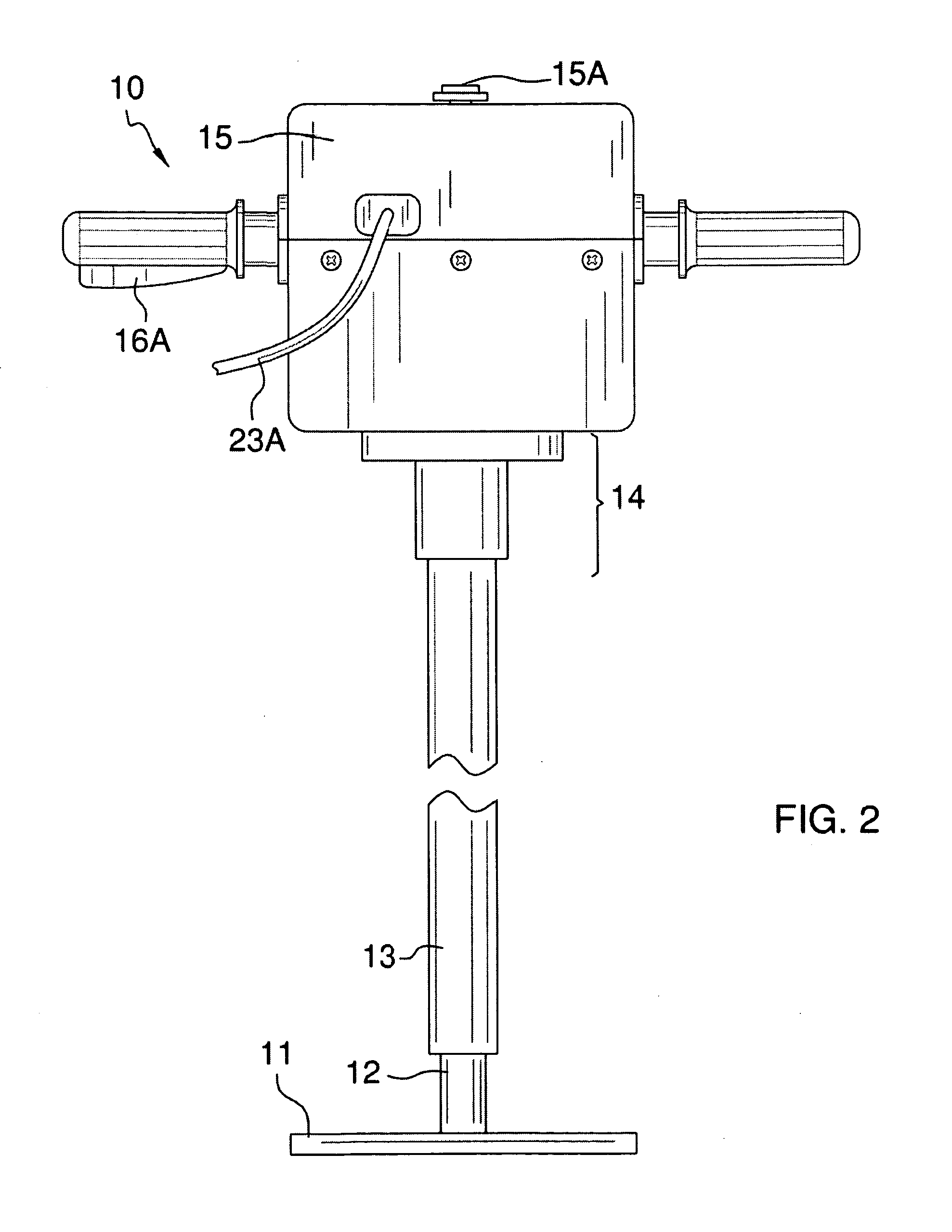

[0027]Detailed reference will now be made to the preferred embodiment of the invention, examples of which are illustrated in FIGS. 1-3. A tamping device 10 (hereinafter invention) comprises a tamping plate 11, reciprocating rod 12, sleeve 13, sub-housing 14, housing 15, and handles 16.

[0028]The sleeve 13 runs along the reciprocating rod 12 and protects the reciprocating rod 12. The sleeve 13 is made of a material comprising a metal, rubber, plastic, or carbon fiber composite. The reciprocating plate 12 shall be no less than 3 feet in overall length. The reciprocating rod 12 shall have the ability to move back and forth within both the sub-housing 14 and the housing 15 via openings 14A / 15B, respectively. A plurality of bushings 148 are included within the sub-housing 14 to enable a means of sealing off the openings 14A / 15B from outside debris while reducing friction between the reciprocating rod and the sub-housing 14.

[0029]The reciprocating plate 12 and the tamping plate 11 are made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com