Method for producing a coupling on a pipe and device for producing said coupling

a technology of pipe and socket, which is applied in the field of making sockets on pipes, can solve the problems of saving significant material expenses, the fitting is exposed to the greatest stress, etc., and achieves the effects of increasing material expenses, increasing wall thickness inherently, and increasing wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

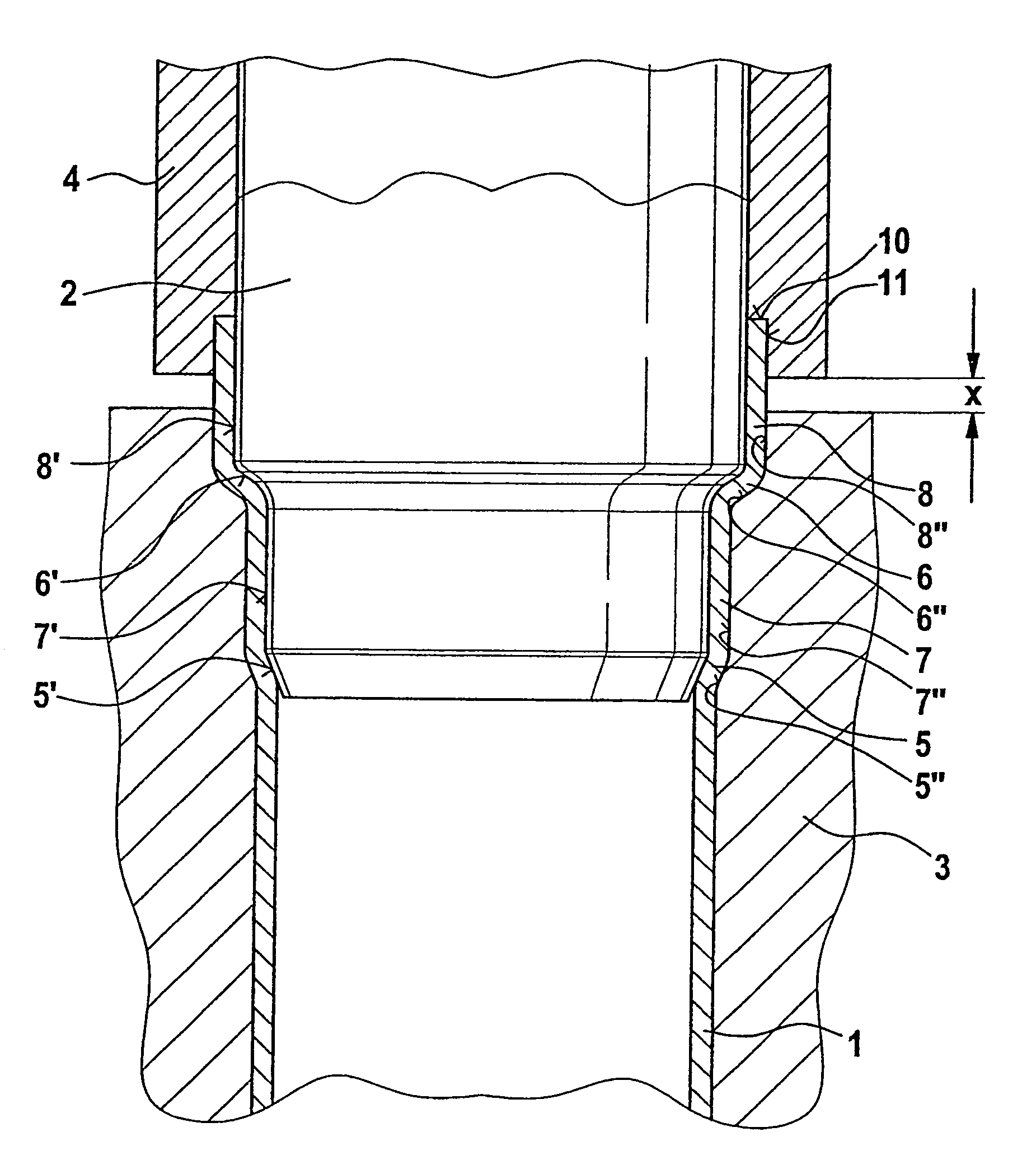

[0012]The finished pipe 1 shown in FIG. 1 has a wall thickness d1 which corresponds to the wall thickness of the original pipe material. Following a two-step expansion, the pipe has a first conical part 5, an adjoining first cylindrical part 7 having a wall thickness d7 which is reduced with respect to the wall thickness d1 in accordance with the extent of the expansion, a second conical part 6, an adjoining second cylindrical part 8 and an inwardly bent flange 9. The second cylindrical part 8 has a wall thickness d8 which, prior to providing the flange 9, was increased to the required extent by means of the upsetting step according to the invention. The wall thickness d8 should at least equal the wall thickness d7. It has even been found advantageous to bring the wall thickness up to the wall thickness d1.

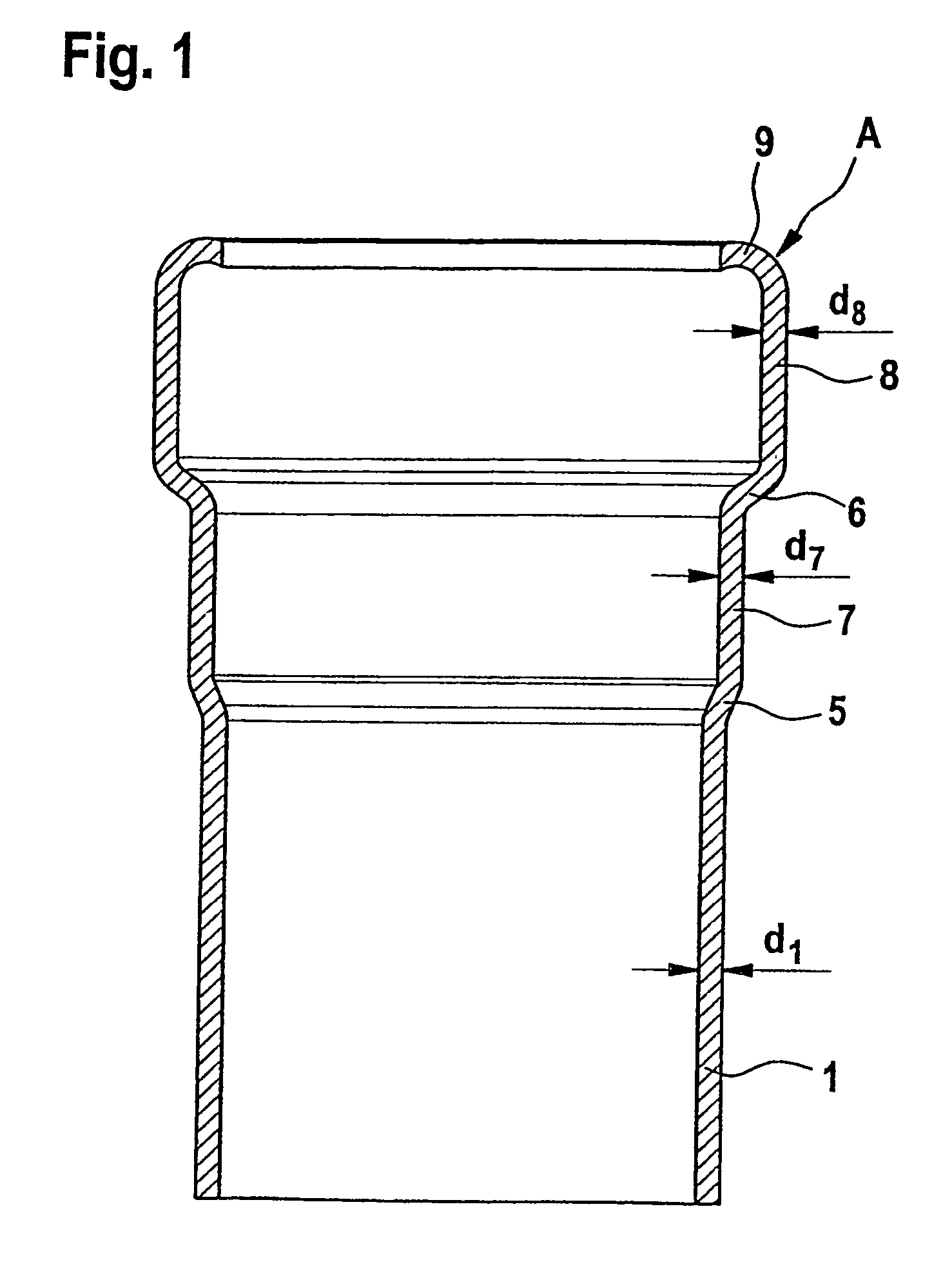

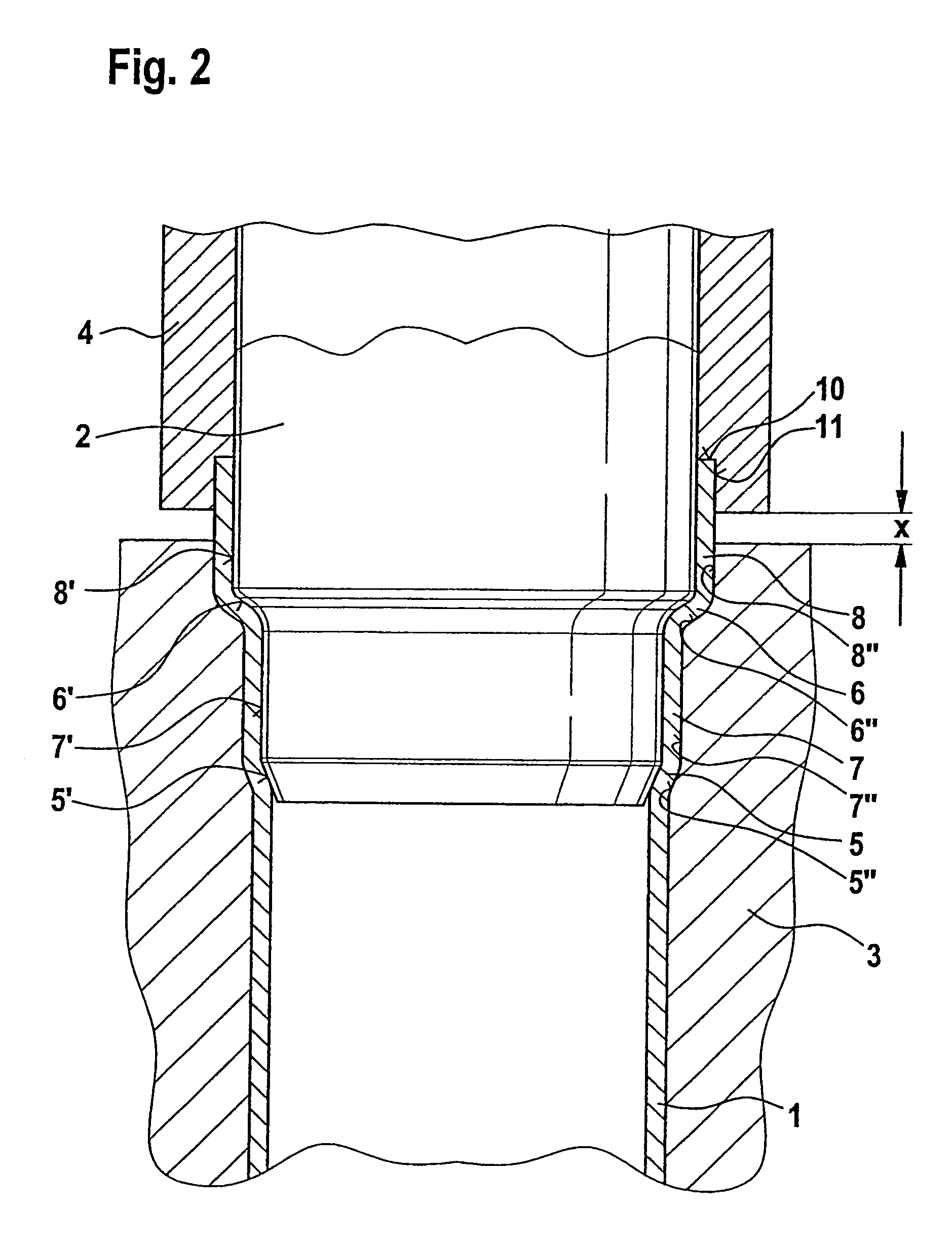

[0013]In FIG. 2 the multi-step expansion tool 2 has already been axially pressed into the pipe end. The shape of the socket having parts 5 to 8 is formed on the inside by the part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com